Hollow electric-rotating connector

A technology of rotary connectors and electrical connectors, applied in the direction of rotary collectors, connections, collectors, etc., can solve the problems that the slip ring sleeve of the electrical rotary connector cannot be installed with other parts, and cannot be connected with equipment, etc., to achieve Reduce heat generation, facilitate disassembly, increase the effect of signal and current channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

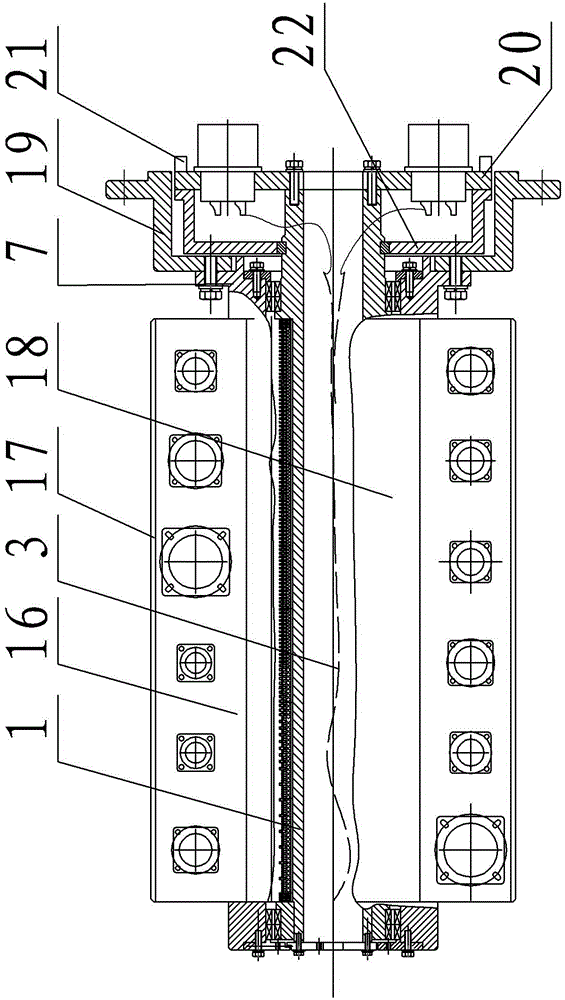

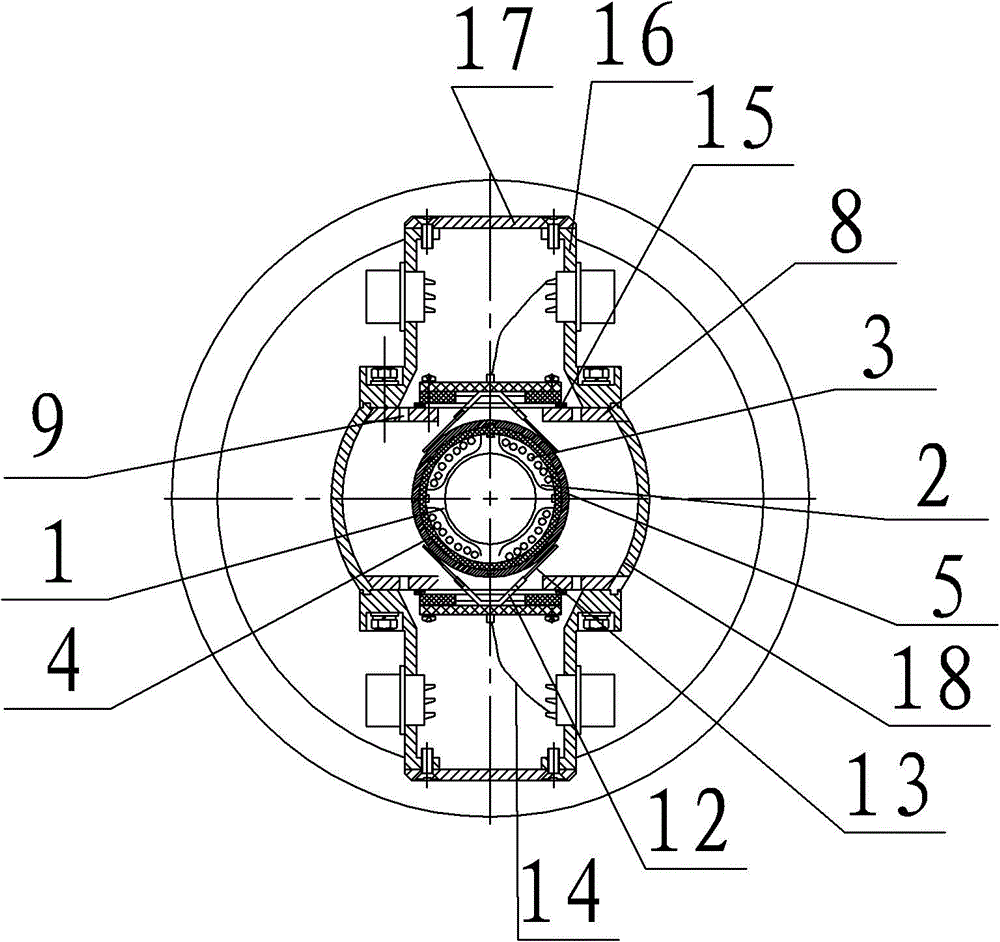

[0018] Such as figure 1 with figure 2As shown, an embodiment of the hollow electric rotary connector of the present invention, the outer wall of the slip ring sleeve 1 is provided with a wire groove 2, the wire groove 2 is provided with a slip ring wire 3, and the outer periphery of the slip ring sleeve 1 is provided with Insulating sleeve 4, the outer circumference of insulating sleeve 4 is provided with a group of electric slip rings 5 in sequence along the axial direction of slip ring sleeve 1, convex keys are arranged on the inner and outer walls of insulating sleeve 4, and the adjacent wires on slip ring sleeve 1 The ribs between the grooves are provided with key grooves corresponding to the convex keys on the inner wall of the insulating sleeve 4, and the inner wall of the electric slip ring 5 is provided with key grooves corresponding to the convex keys on the outer wall of the insulating sleeve 4. The slip ring sleeve 1 and the electric slip ring 5 and the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com