Knee joint including manual lock mechanism and artificial thigh

A technology of locking mechanism and coupler, applied in artificial legs, medical science, prosthesis, etc., can solve the problems of difficult to realize compact structure of knee coupler and prosthesis, many components, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

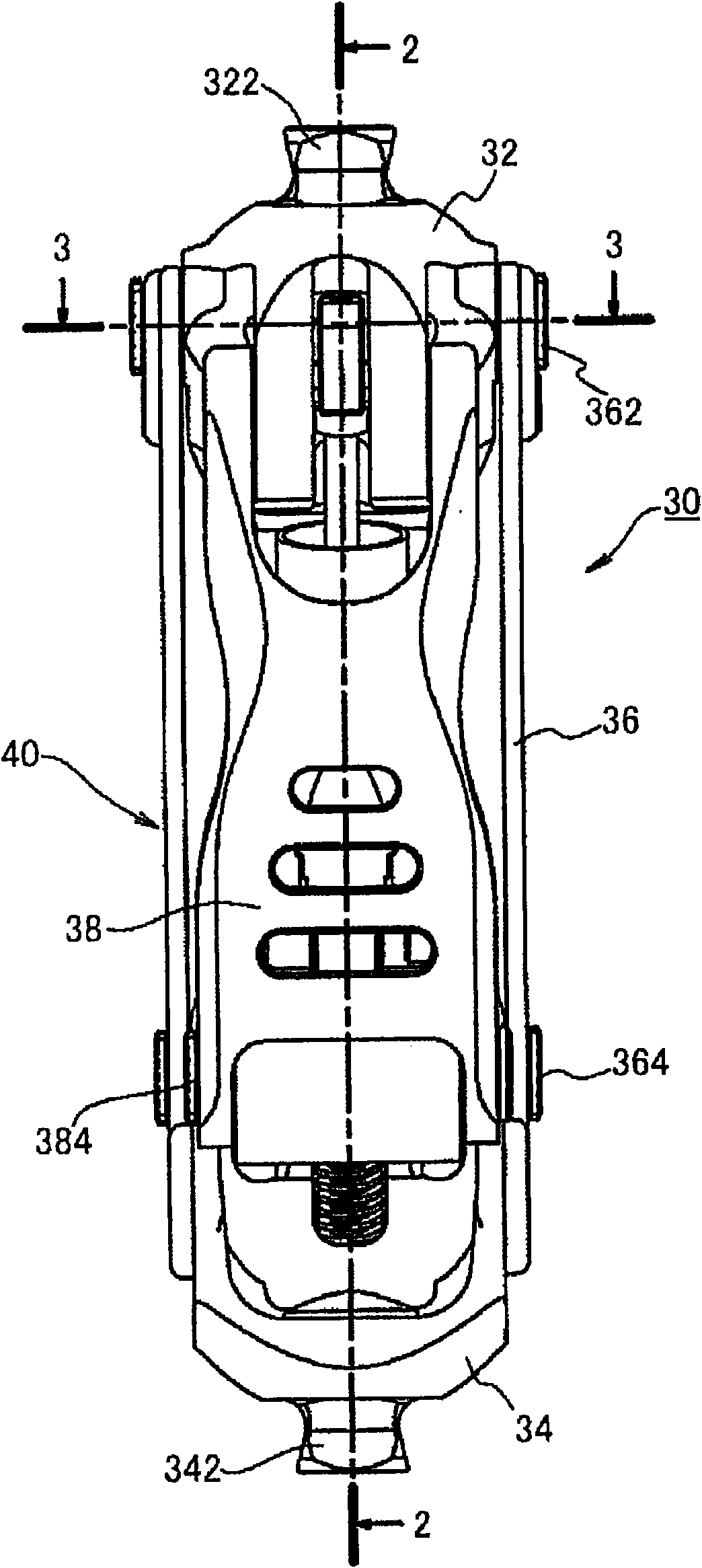

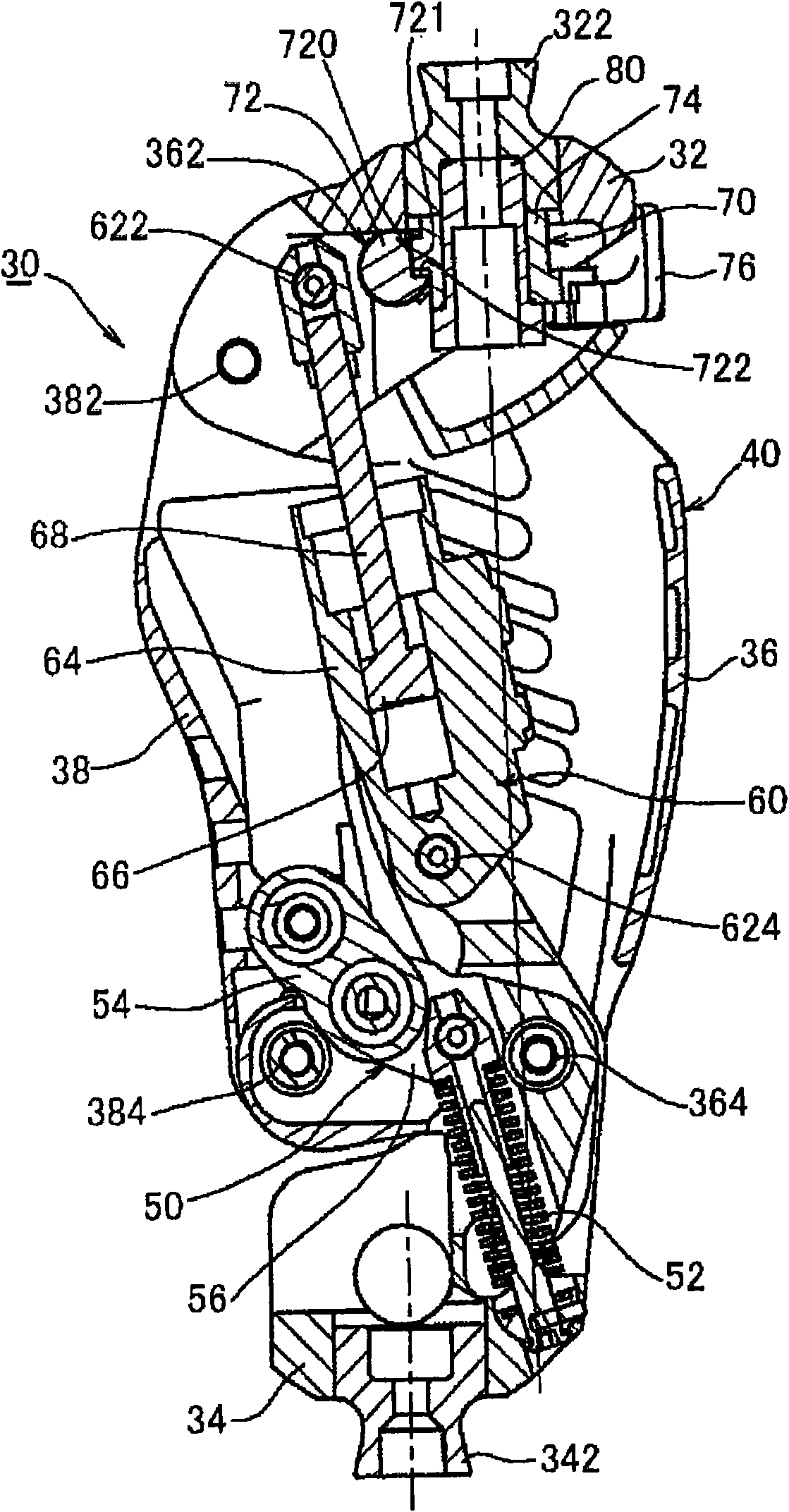

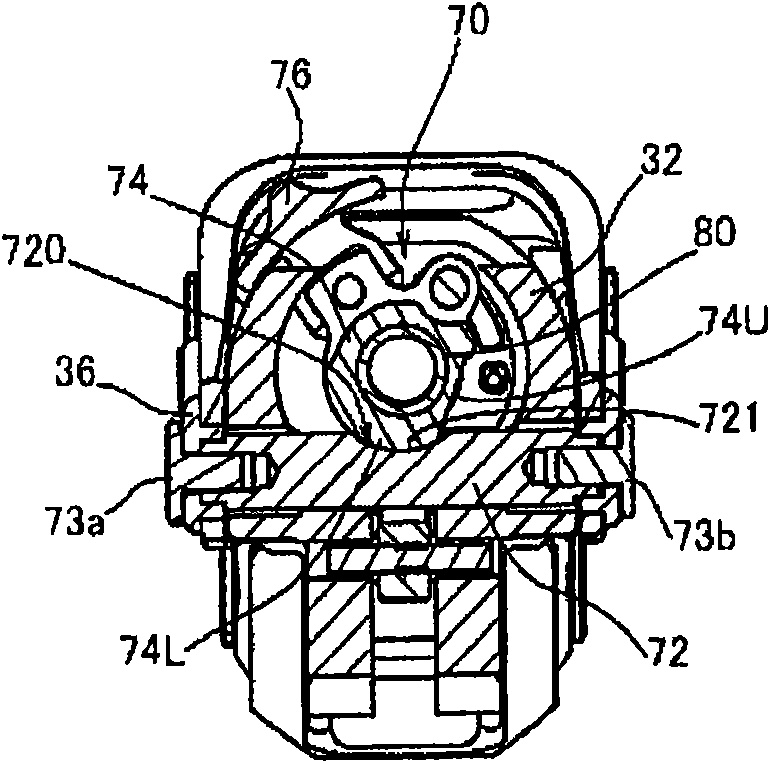

[0067] Figure 1 ~ Figure 3 This is the first embodiment of applying the present invention to a multi-axis knee joint. The knee coupler 30 of the first embodiment includes an upper member 32 located on the upper side of the knee, and a lower member 34 located on the lower side of the knee and swingably connected to the upper member 32 to allow the knee to bend. The upper member 32 integrally supports the positioning block 322 at the upper central part. The positioning block 322 is a part to which a sleeve (not shown) is attached, and supports the load of the prosthetic user by inserting the thigh of the sleeve. On the other hand, another positioning block 342 is also provided in the lower center of the lower member 34. The positioning block 342 is a part where a foot member for supporting the foot is installed. Thus, the knee coupling 30 constitutes the main part of the thigh prosthesis.

[0068] The multi-axis connecting device 40 connects the upper member 30 and the lower me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com