Peanut combine

A technology for combine harvesters and peanuts, which is applied in the direction of excavator harvesters, harvesters, agricultural machinery and implements, etc., which can solve the problem of too much soil at the root of clamping and conveying, poor cleaning effect of vibrating screen, and poor feeding performance. ideals etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

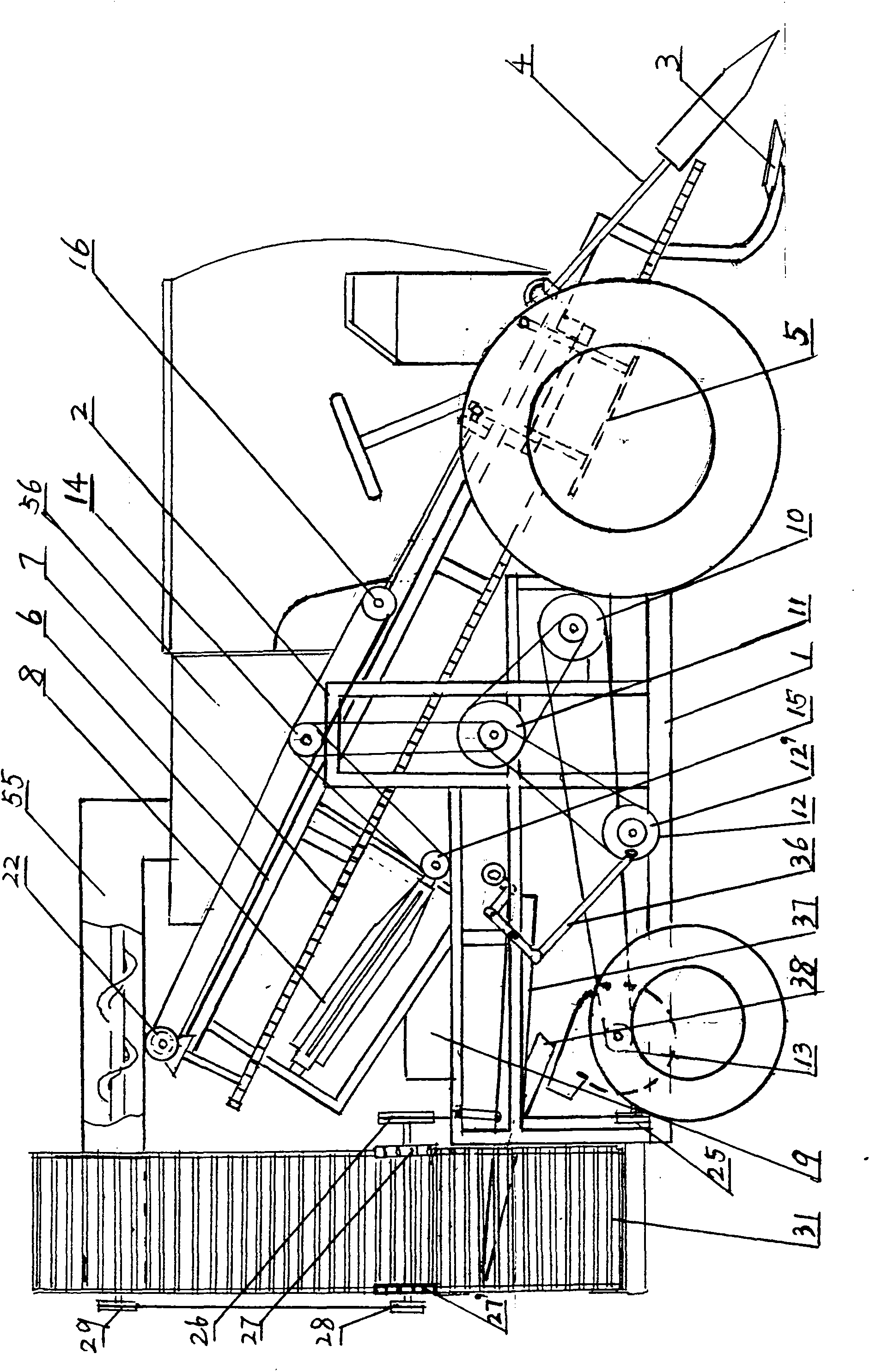

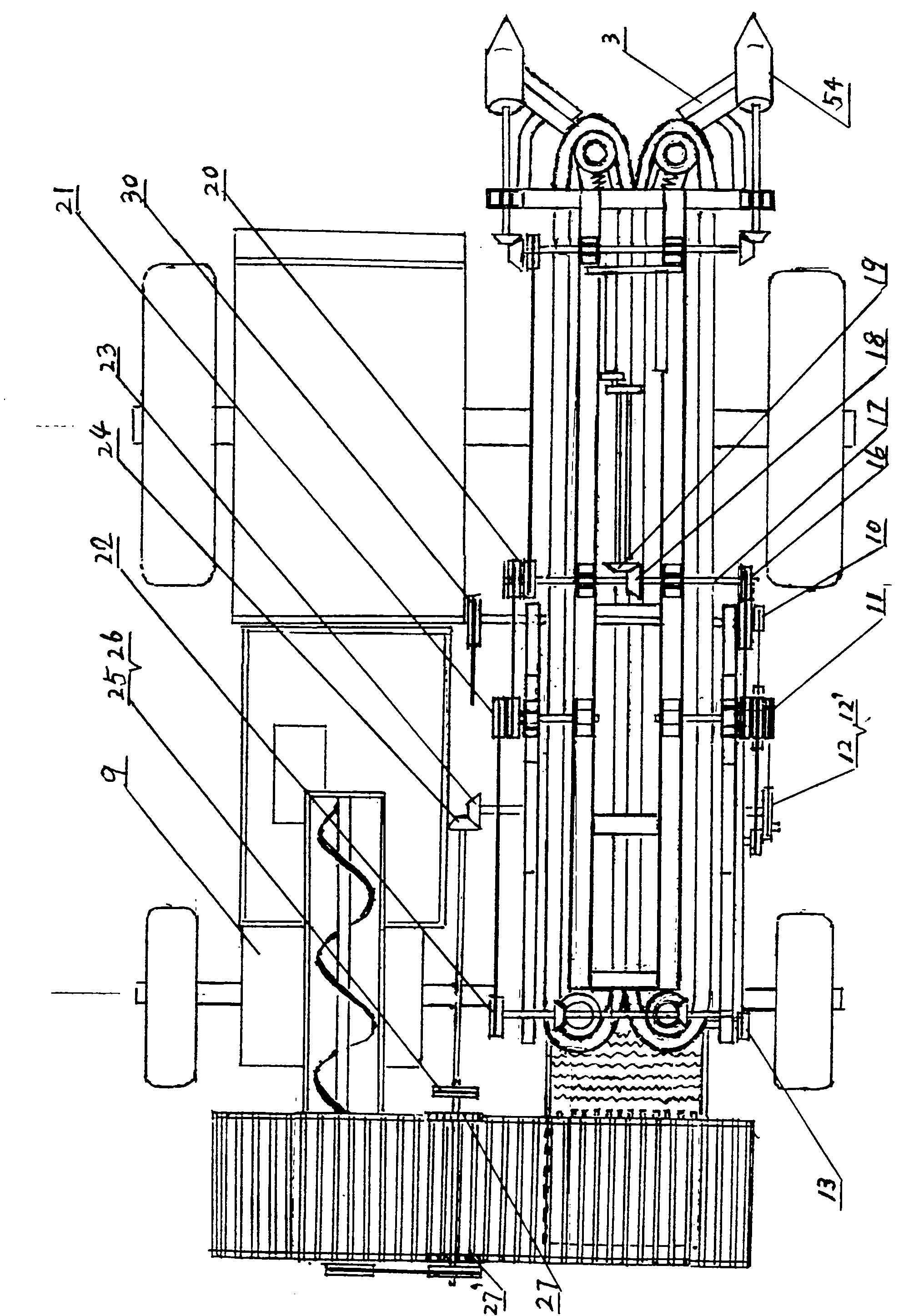

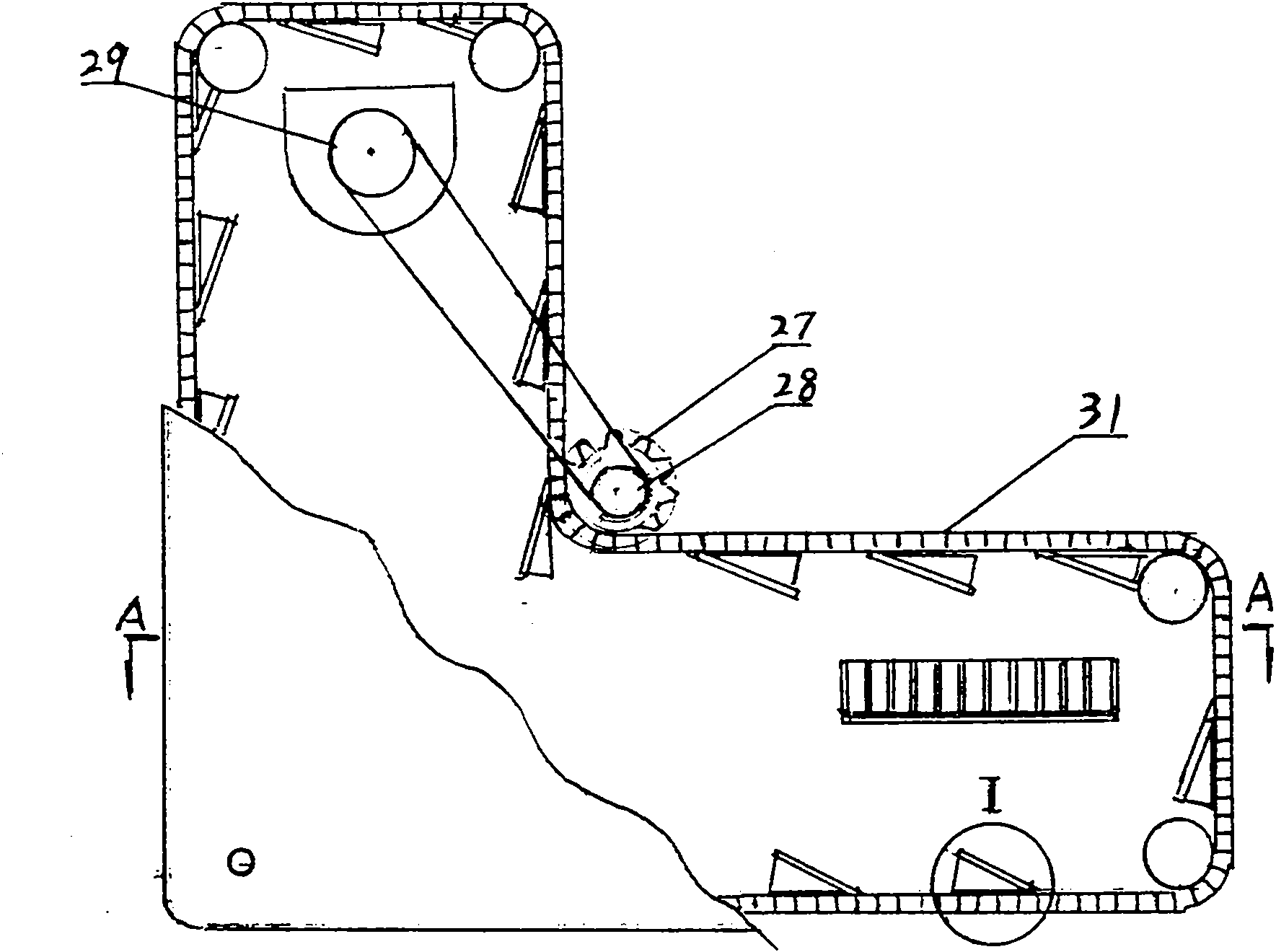

[0015] Above-mentioned accompanying drawing has provided a kind of specific embodiment of the present invention, below in conjunction with accompanying drawing the content of the present invention is described in detail as follows: the present invention comprises the running mechanism that is made of road wheel and chassis 1, and one side is provided with engine 9 on the chassis With the power take-off wheel 30 that is connected with the engine power output, the engine power output is also connected with the transmission box to provide walking power simultaneously, before the engine is the driving operation room, and the upper part of the engine is provided with a collection fruit box 56 to be connected with the stirring cage 55. The other side of the chassis is provided with a combined peanut harvesting device, including a power transmission system composed of a driving wheel 10 and a drive wheel; The side fulcrum shaft (that is, the fulcrum half shaft on which the fulcrum dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com