Processing method of cigarettes with low crotonaldehyde content

A processing technology, soybean aldehyde technology, applied in the direction of tobacco, tobacco preparation, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

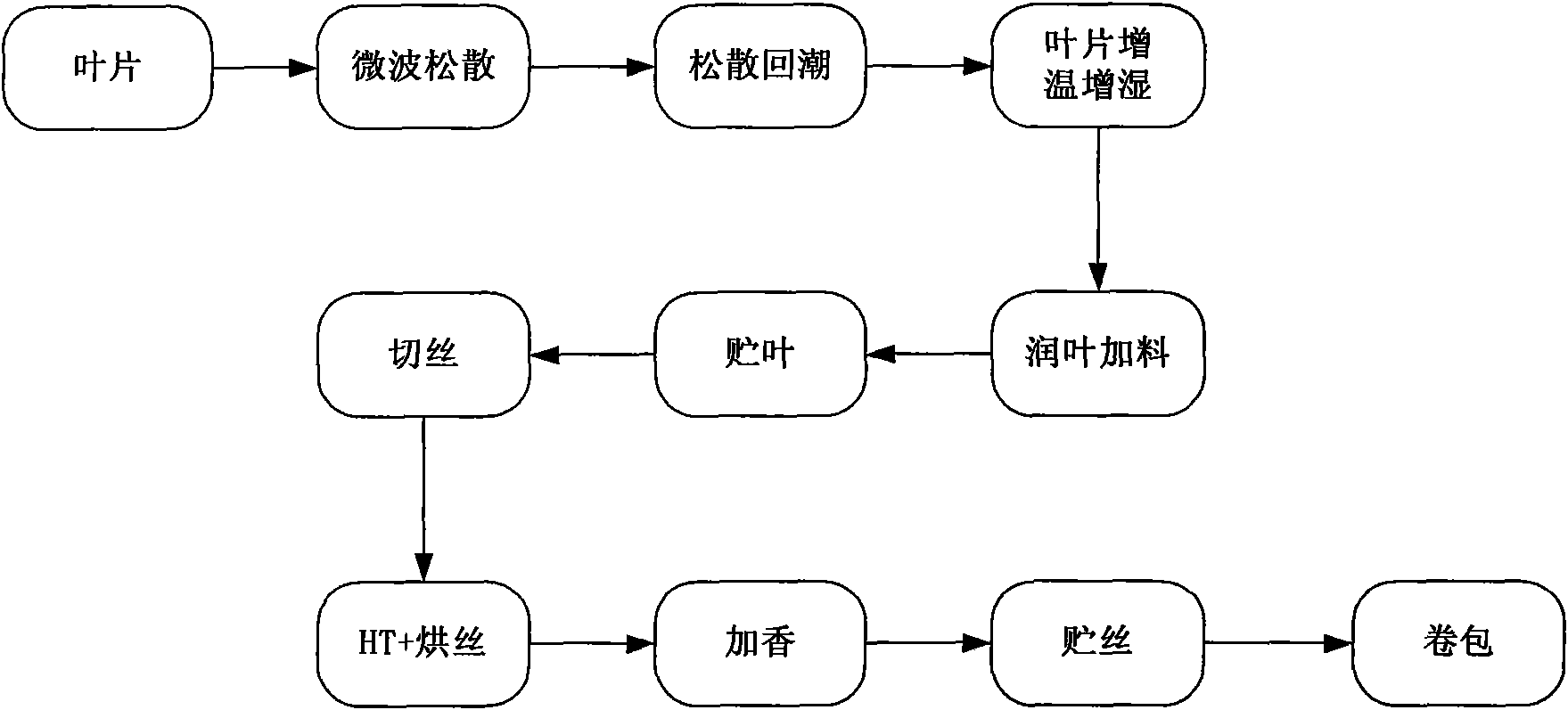

Method used

Image

Examples

Embodiment 1

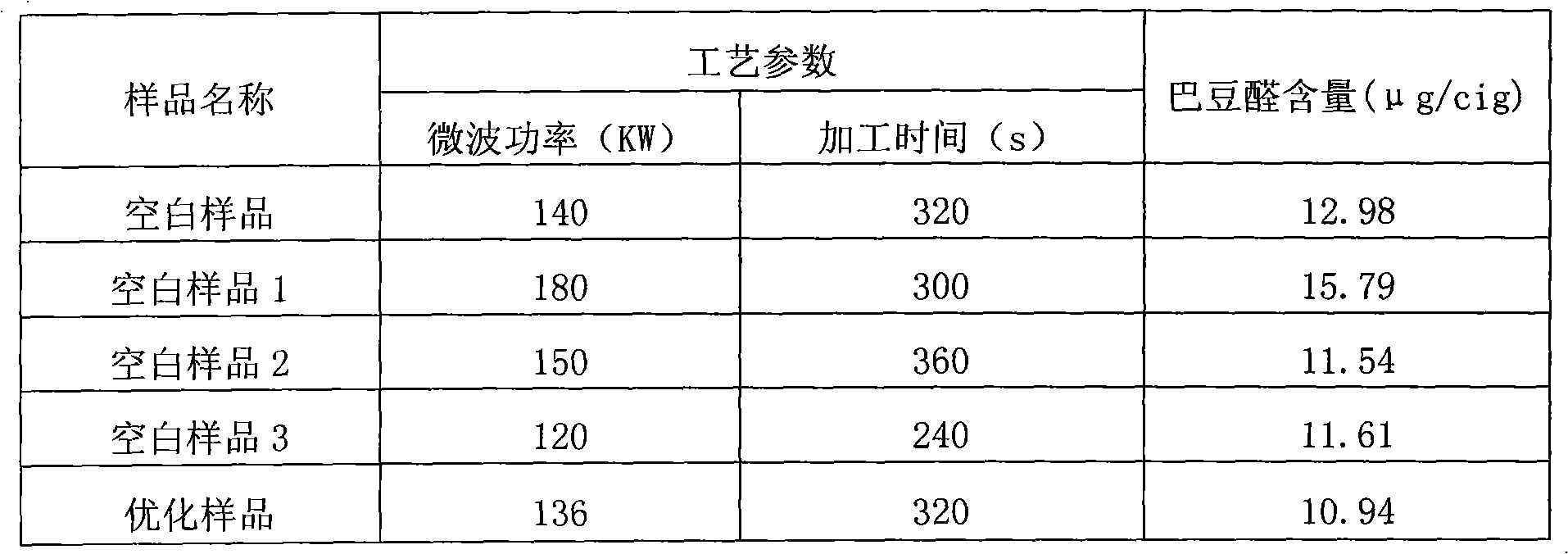

[0018] The tobacco sample produced according to the established cigarette shred process parameters was used as a blank sample; in the microwave loosening process, the process parameters were adjusted according to the combination of microwave power 136KW and processing time 320s, and the process parameters of other processes were unchanged, and the production obtained The tobacco samples of the two samples are optimized samples;

[0019] Table 1 Detection results of crotonaldehyde content in samples optimized for microwave loosening process and blank samples

[0020]

[0021] It can be seen from Table 1 that the crotonaldehyde content in the flue gas of the tobacco samples produced under the combination of microwave loose optimization process parameters is 15.72% lower than that of the blank sample, which has an obvious effect of reducing the crotonaldehyde content.

Embodiment 2

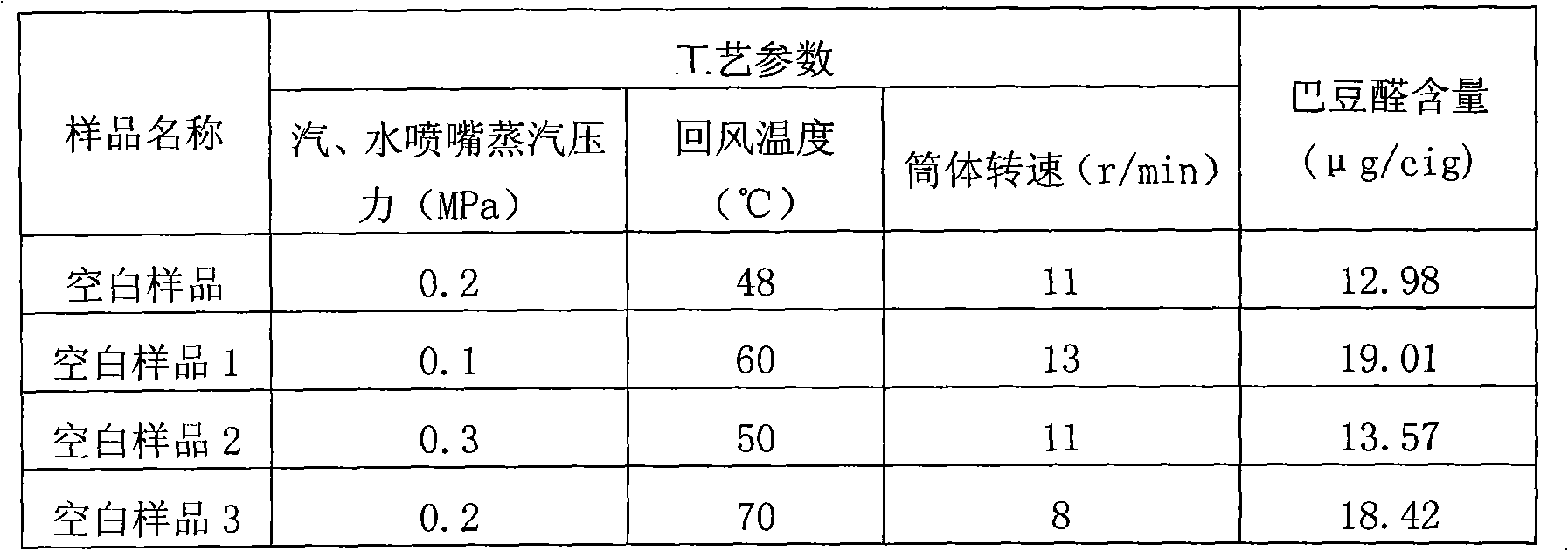

[0023] Tobacco samples produced according to the established cigarette shred process parameters were used as blank samples; in the loosening and moisture regaining process, the optimized processing parameters were based on the steam pressure of the steam and water nozzles of 0.3MPa, the return air temperature of 48°C, and the cylinder speed of 9r / min The process parameters were adjusted in combination, and the process parameters of the other processes were kept unchanged. The tobacco samples produced were optimized samples;

[0024] Table 2 Detection results of the content of crotonaldehyde in the optimized sample and the blank sample in the loose moisture regain process

[0025]

[0026]

[0027] It can be seen from Table 2 that the content of crotonaldehyde in the flue gas of the tobacco samples produced under the combination of loose moisture regain optimization process parameters is 14.64% lower than that of the blank sample, which has an obvious effect of reducing th...

Embodiment 3

[0029] The tobacco sample produced according to the established cigarette shred process parameters is used as a blank sample; in the HT + shred drying process, the working steam pressure of HT is 0.60MPa, the hot air temperature is 85°C, the moisture exhaust damper opening is 53%, and the hot air damper opening is 70 %, cylinder speed 9r / min optimized processing parameters combined to adjust the process parameters, the remaining process parameters remain unchanged, the tobacco sample produced is the optimized sample; the detection of the crotonaldehyde content in the smoke of the two samples is shown in Table 3.

[0030] Table 3 Detection results of crotonaldehyde content in samples optimized for HT+drying process and blank samples

[0031]

[0032] It can be seen from Table 3 that the content of crotonaldehyde in the flue gas of the tobacco samples produced under the combination of HT+shred drying optimization process parameters is 56.01% lower than that of the blank sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com