Improved structure for branch crusher

A shredder and branch technology, applied in grain processing, etc., can solve the problems of affecting the service life of blades, incomplete crushing of branches, easy blockage of chip removal, etc., to achieve sufficient chip removal, thorough crushing of branches, and low working noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

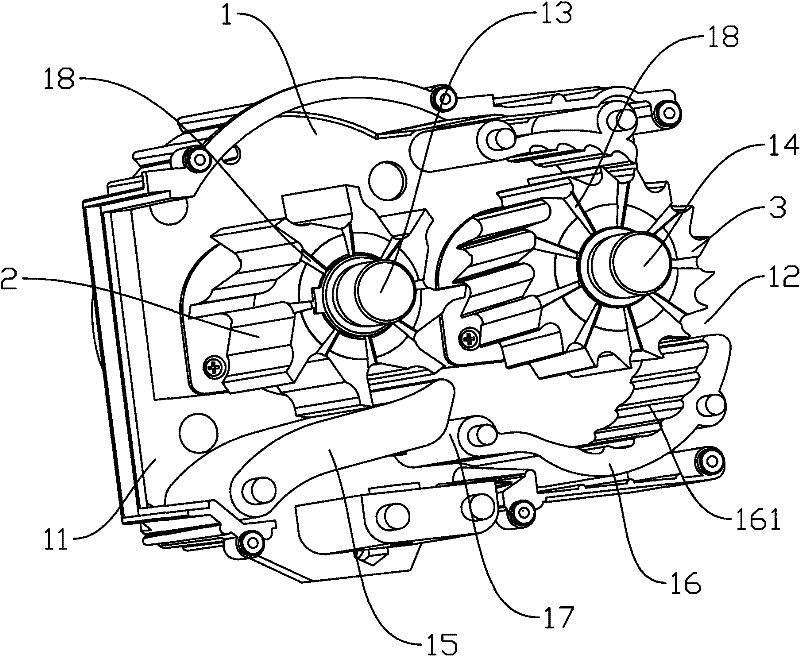

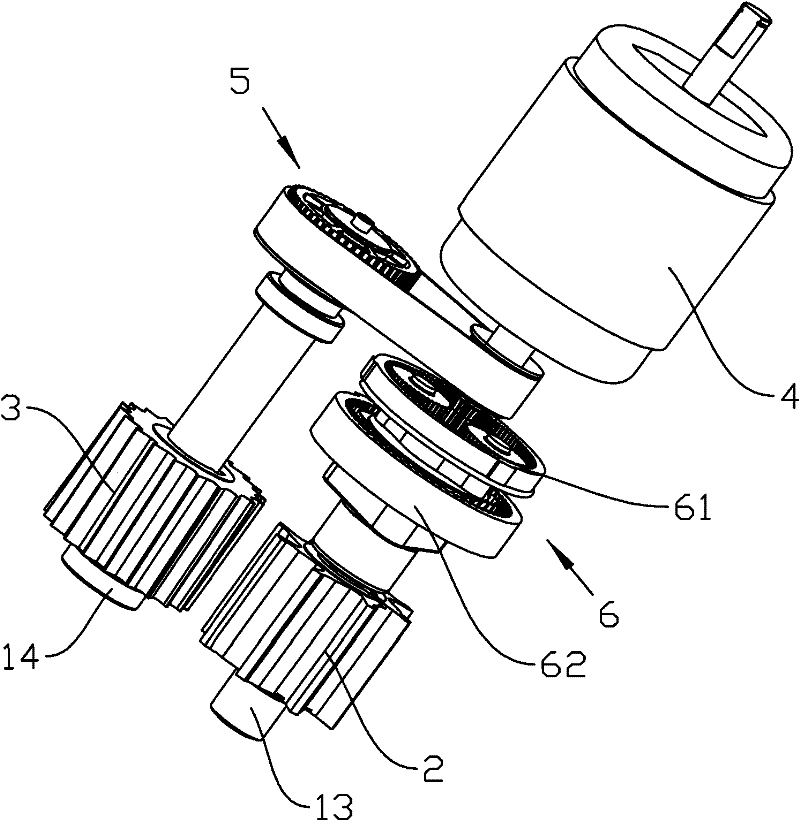

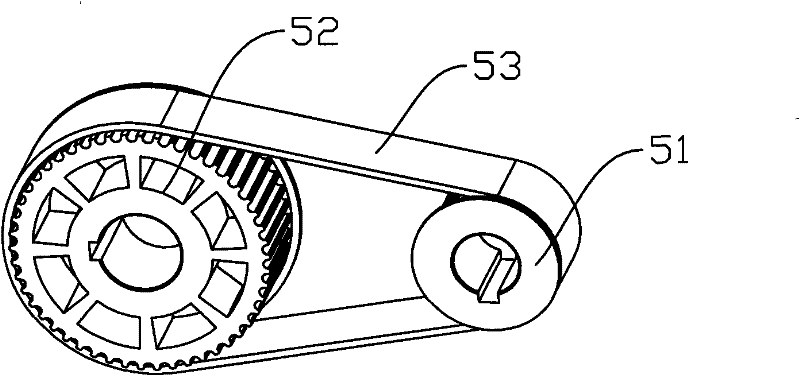

[0021] Such as Figures 1 to 5 Shown is a structural schematic diagram of an embodiment of the present invention, an improved structure of a branch crusher, comprising a housing 1, one end of the housing is provided with a material inlet 11, and the other end of the housing is provided with a material outlet 12, and the housing is provided with a material outlet 12. One side of the material inlet in the body is connected to the first-stage hob 2 through the first-stage hob shaft 13, and the second-stage hob 3 is connected to the side of the discharge port in the housing through the second-stage hob shaft 14. The first-stage hob The knife and the secondary hob are simultaneously driven by the drive motor 4 through the transmission mechanism and turn to the same direction. The transmission mechanism includes a belt drive assembly 5 connected to the secondary hob and a two-stage planetary transmission assembly 6 connected to the primary hob. Described belt transmission assembly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com