Pinion inner hole honing tool

A pinion and honing technology, applied in the field of mechanical parts processing, can solve problems such as small modulus, failure to meet the use requirements, unstable product quality, etc., achieve easy operation, improve convenience, accuracy and stability, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

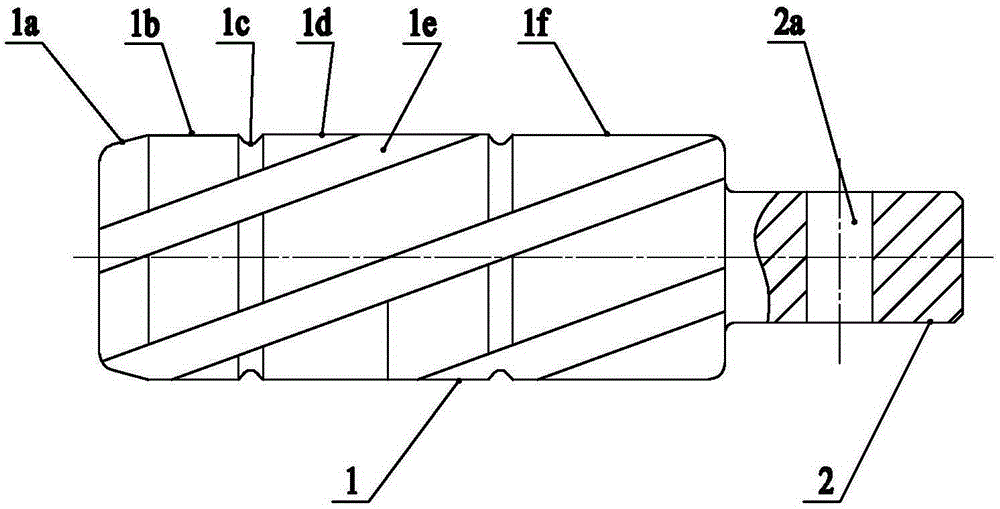

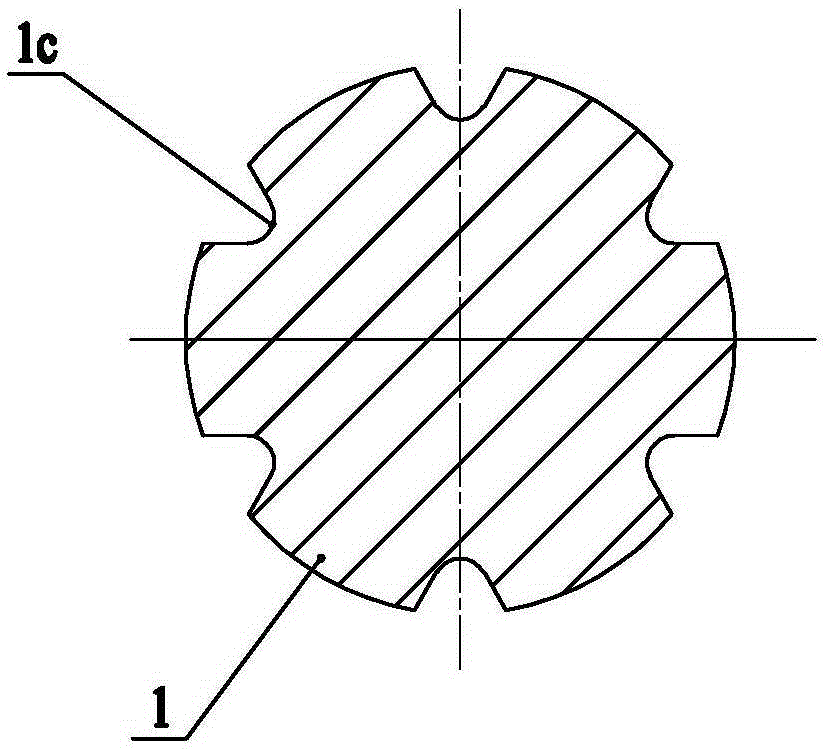

[0023] As shown in the figure: the pinion inner hole honing tool in the embodiment mainly includes a cutter body part 1 and a tool handle part 2, and several parallel spiral chip removal grooves 1e and 2 are milled on the outer surface of the cutter body part 1. Two mutually parallel annular grooves 1c, the cutter body 1 is divided into the cutter body front end 1b, the cutter body main body 1d and the cutter body rear end 1f by the two annular grooves 1c; There are pin holes 2a.

[0024] In the present invention, the material of the honing cutter is No. 45 steel, which is readily available and cheap.

[0025] Such as figure 1 As shown, in the present invention, the front end portion 1b of the cutter body plays a stabilizing role during reaming, making the reaming process more stable. The front end of the front end portion 1b of the cutter body is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com