Laser tailor-welded weld rolling preforming combined pressing wheel

A technology of preforming and rolling wheels, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing equipment cost, reducing equipment operation efficiency, and the edge of steel plate cannot be accurate and straight, so as to eliminate the welding seam Clearance, increased rigidity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

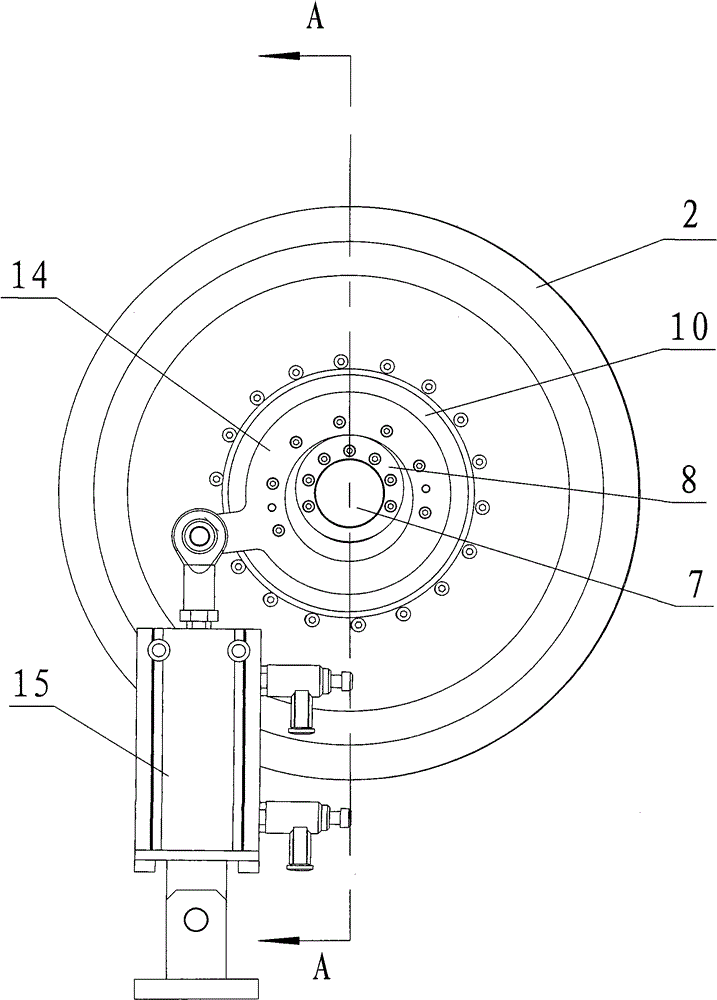

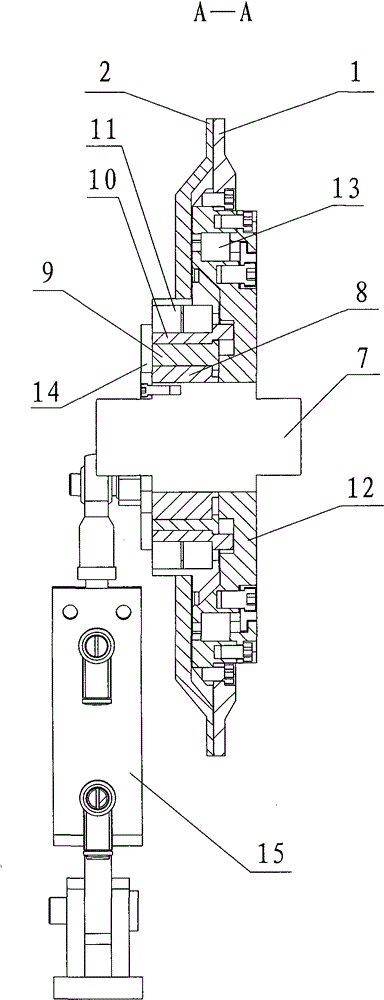

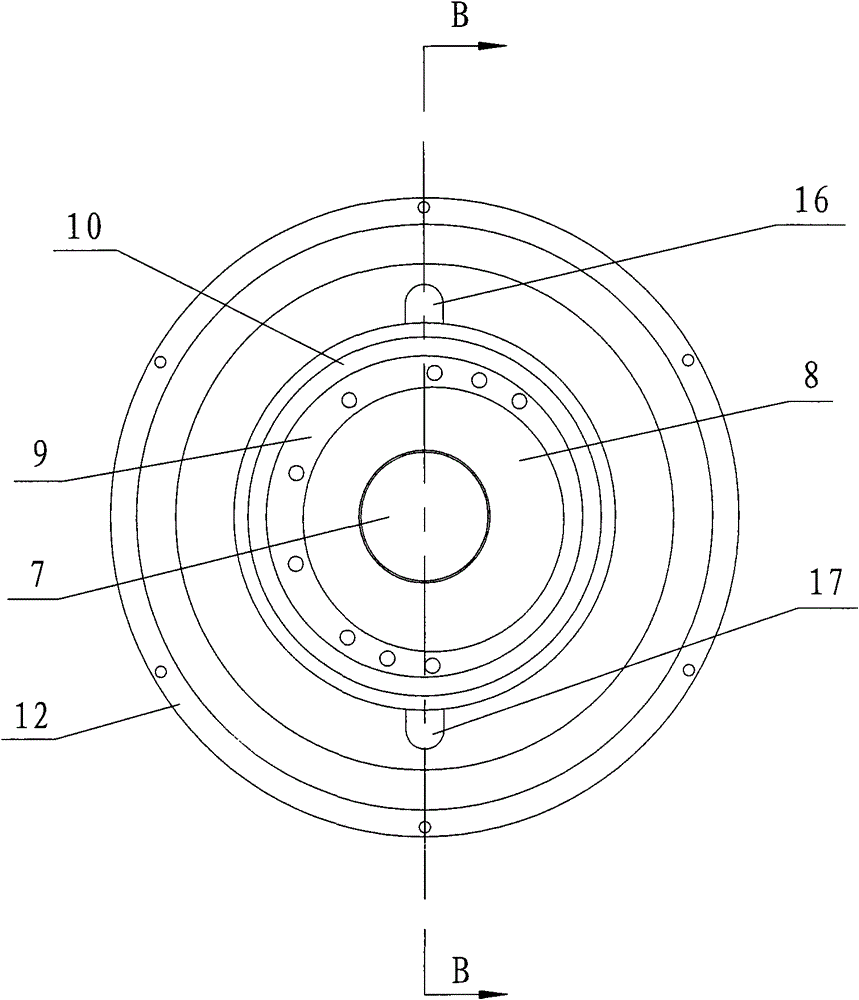

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Such as Figure 1~4 As shown, the present invention includes rolling wheel 1, pressing wheel 2, pressing wheel shaft 7, inner layer eccentric sleeve 8, outer layer eccentric sleeve 9, rotary sleeve 10, rear end cover 12, connecting cover 14 and drive cylinder 15, pressing The wheel shaft 7 is installed on the laser tailor welding machine. One side of the pressure wheel shaft 7 is set with an inner eccentric sleeve 8, an outer eccentric sleeve 9 and a rotary sleeve 10 in sequence from the inside to the outside, that is, the inner eccentric sleeve 8 is set on the pressure wheel shaft. 7, the outer eccentric sleeve 9 is set on the inner eccentric sleeve 8, and the outer eccentric sleeve 9 is provided with a rotary sleeve 10, and the other side of the pressing wheel shaft 7 is provided with a rear end cover 12; the rolling wheel 1 passes The rolling wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com