Gas film ice prevention structure of leading edge of nacelle of airplane

A nacelle and leading edge technology, applied in the aviation field, can solve the problems of hot air energy waste, poor timeliness of the outer wall, slow speed, etc., to achieve high heat utilization, high work reliability, and reduce head loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

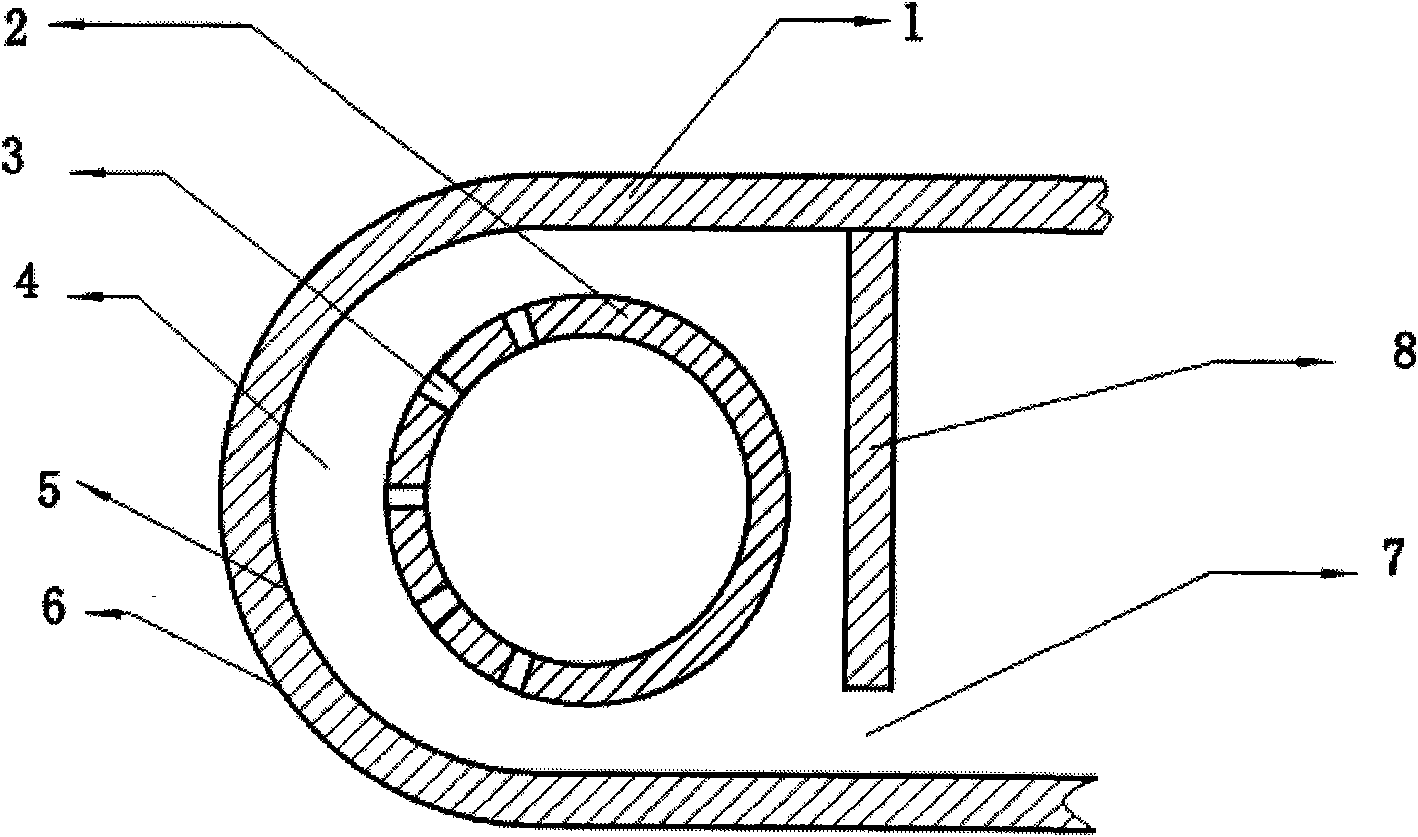

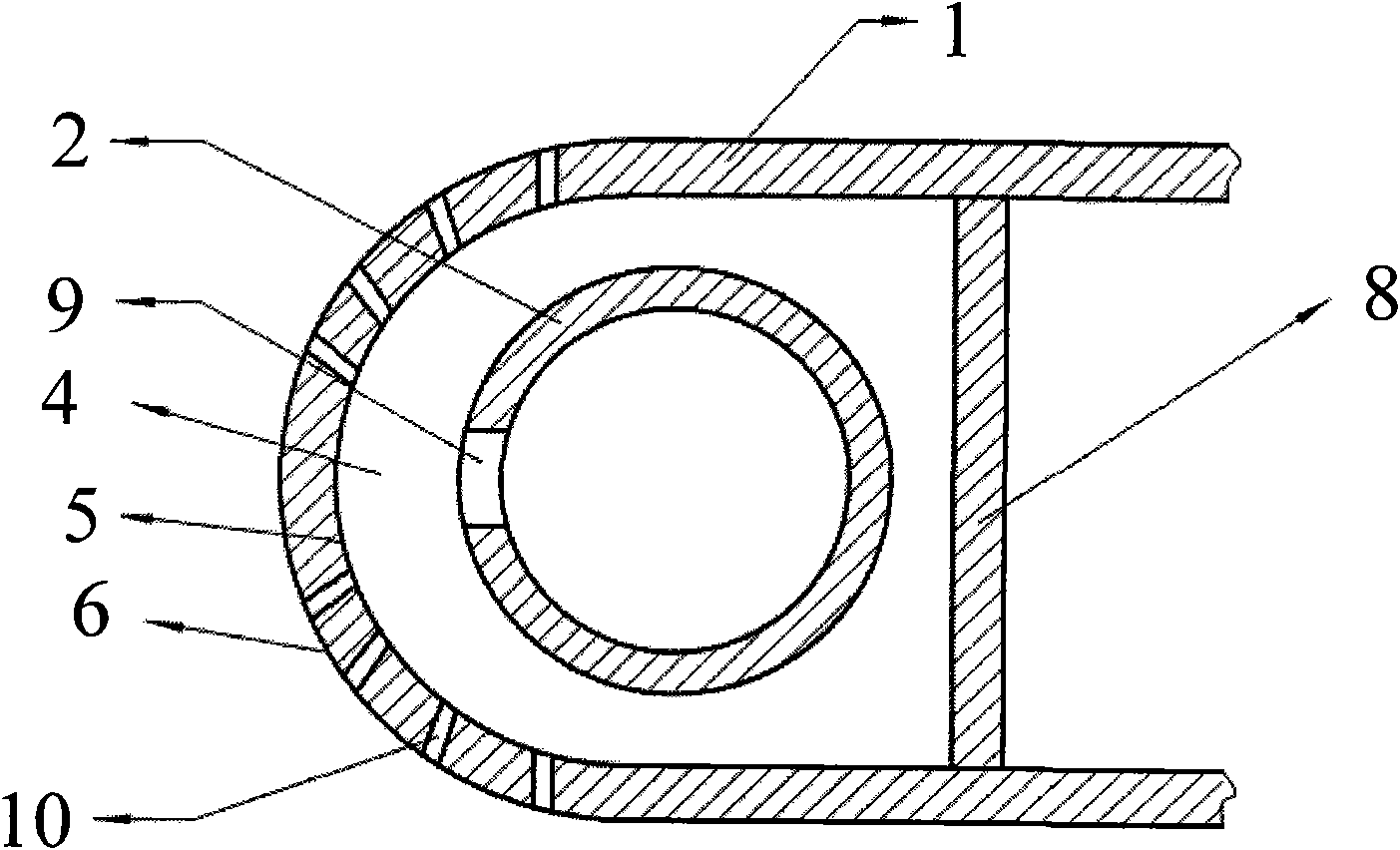

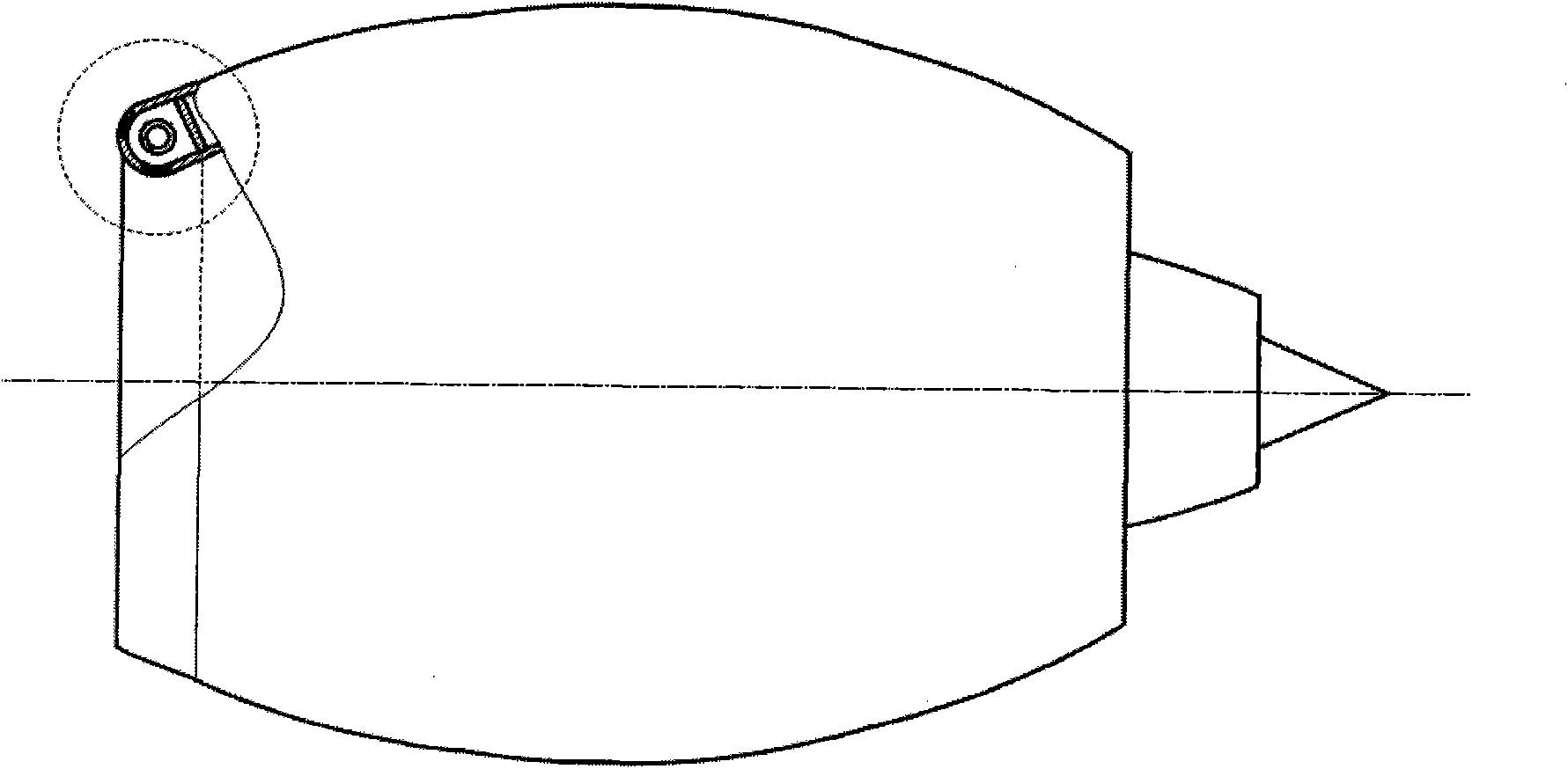

[0020] The present invention is an air film type anti-icing structure at the leading edge of an aircraft nacelle, such as figure 2 As shown, it includes a nacelle outer wall 1, an annular hot gas pipe 2 and a support plate 8.

[0021] The annular hot gas pipe 2 is located in the anti-icing cavity 4 formed by the outer wall 1 of the nacelle and the support plate 8. Both ends of the support plate 8 are fixedly connected to the outer wall 1 of the nacelle. Flow holes 9 and air film holes 10 are provided on the outer wall 1 of the nacelle.

[0022] The size of the outlet hole 9 in the annular hot gas pipe 2 is determined according to the size of the specific engine annular hot gas pipe 2, and the air film holes 10 are distributed along the circumferential direction and the entire circumferential direction of the front edge of the nacelle outer wall 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com