Catapult used on aircraft carrier

A technology of aircraft carrier and catapult, which is applied in the direction of launching/dragging transmission device, etc. It can solve the problems of high cost of operation and maintenance, reduced ejection force of catapult, and reduced rotation speed, etc., and achieves low ejection cost, high take-off speed, and strong explosive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

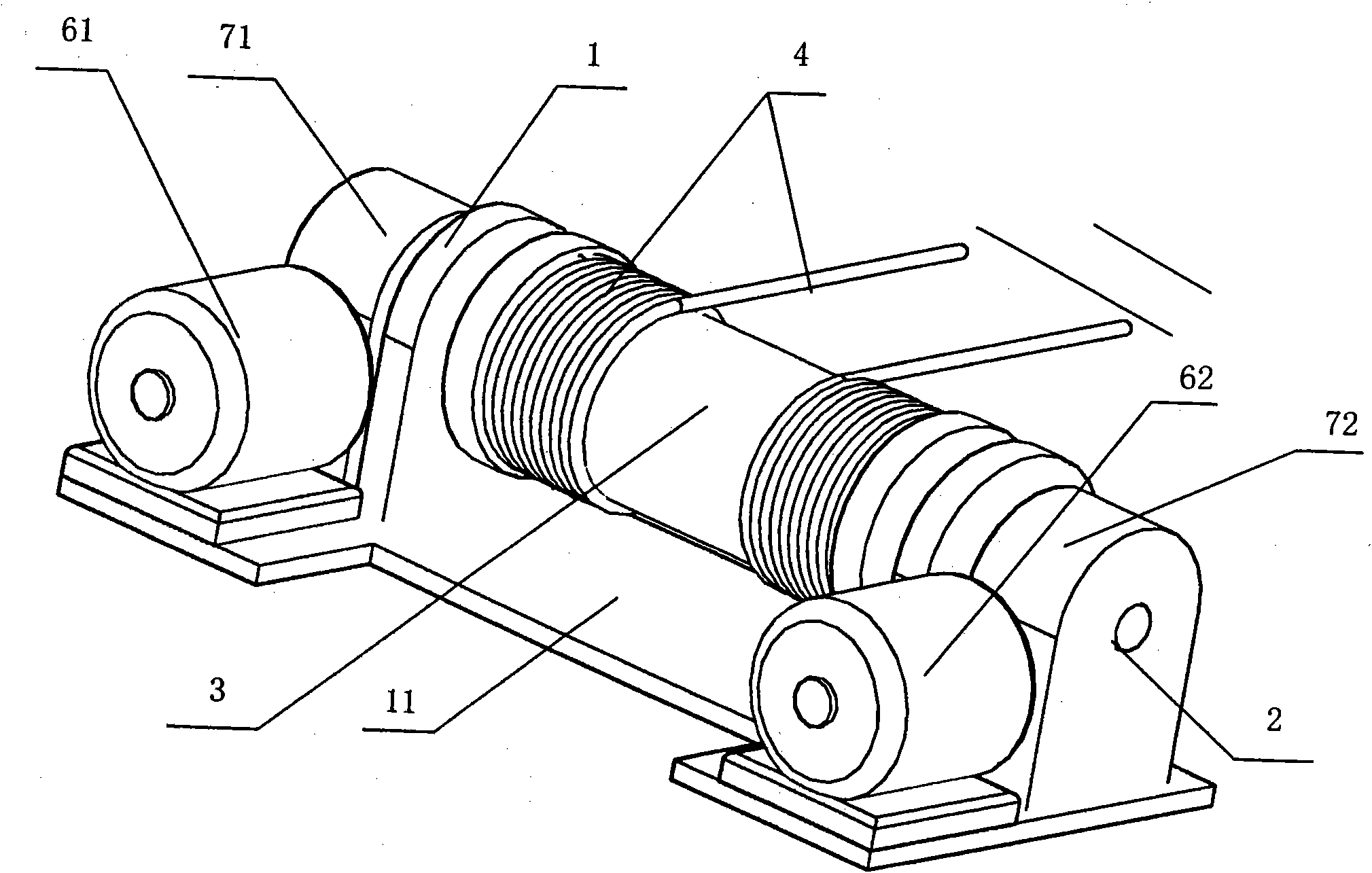

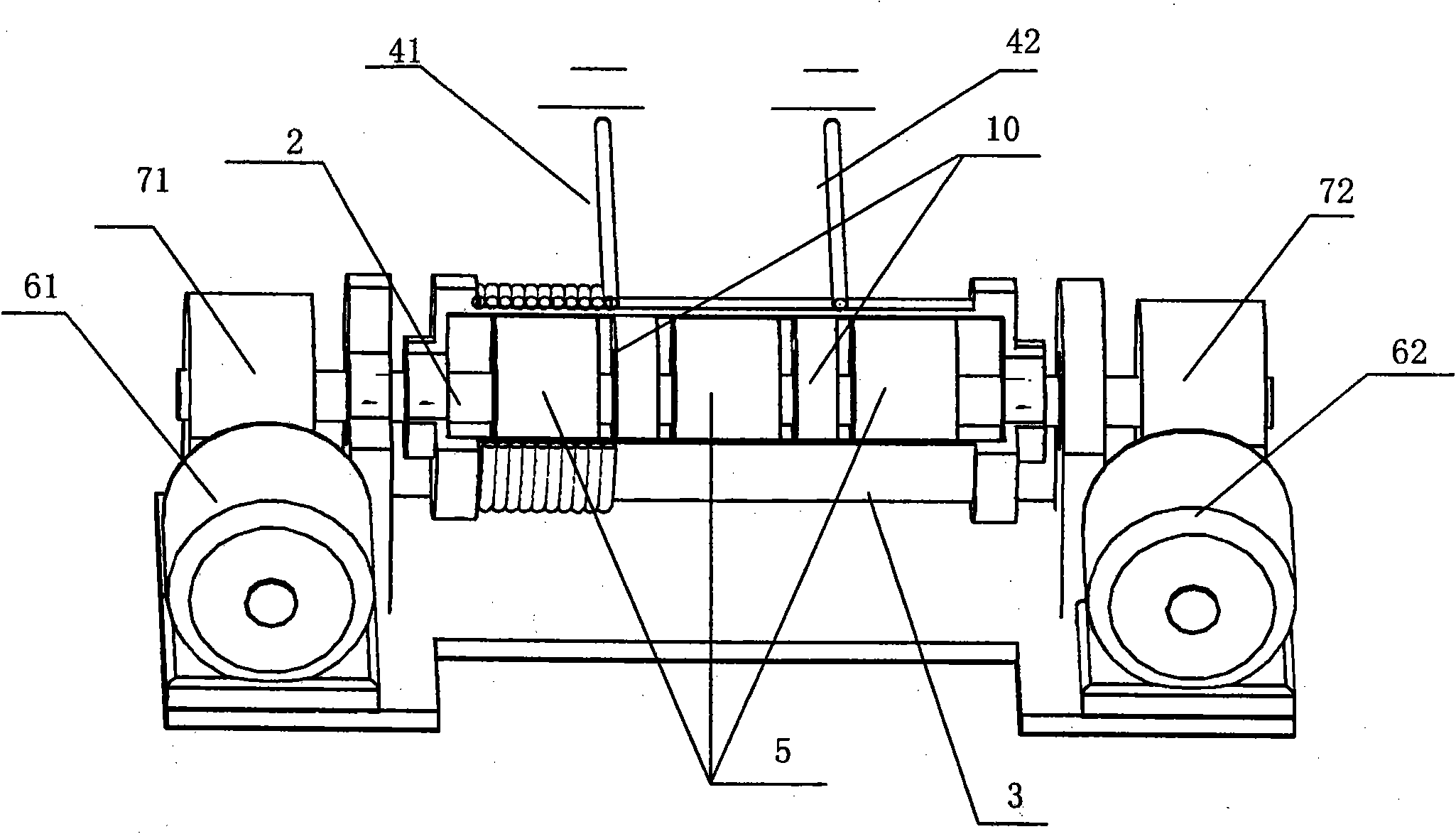

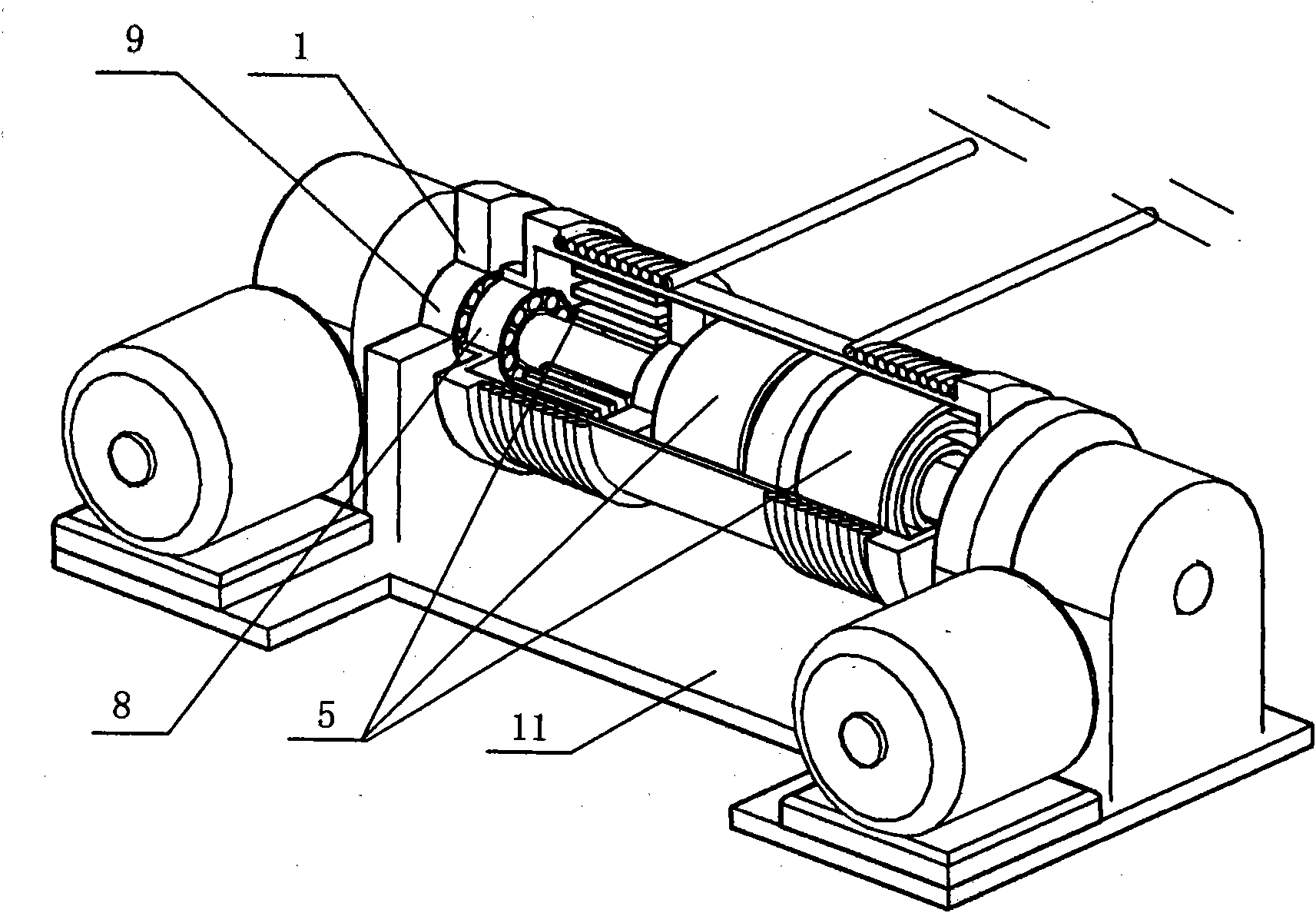

[0023] A catapult for an aircraft carrier, comprising a power system and a seat frame 1, a rotating shaft 2 is mounted on the seat frame 1, a cylinder 3 is arranged outside the rotating shaft 2, and at least one traction cable is wound around the cylinder 3 4. At least one spring-type steel plate 5 is arranged between the rotating shaft 2 and the inner wall of the cylinder 3 , the traction cable 4 is connected with a tractor (not shown in the figure), and the power system is connected with the rotating shaft 2 .

[0024] The power system includes two motors and two reducers, which are respectively the first motor 61, the second motor 62, the first reducer 71 and the second reducer 72, and the first motor 61 is connected to the rotating shaft 2 through the first reducer 71. One end is connected, and the second motor 62 is connected with the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com