Easily opened crown-shaped bottle cap and manufacturing method thereof

A crown-shaped bottle cap and a manufacturing method technology are applied in the field of easy-open crown-shaped bottle caps for glass bottles, which can solve the problems of glass bottle bursting danger, bottle mouth contusion, consumer inconvenience, etc., so as to improve the reuse rate and reduce explosion Bottle danger, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

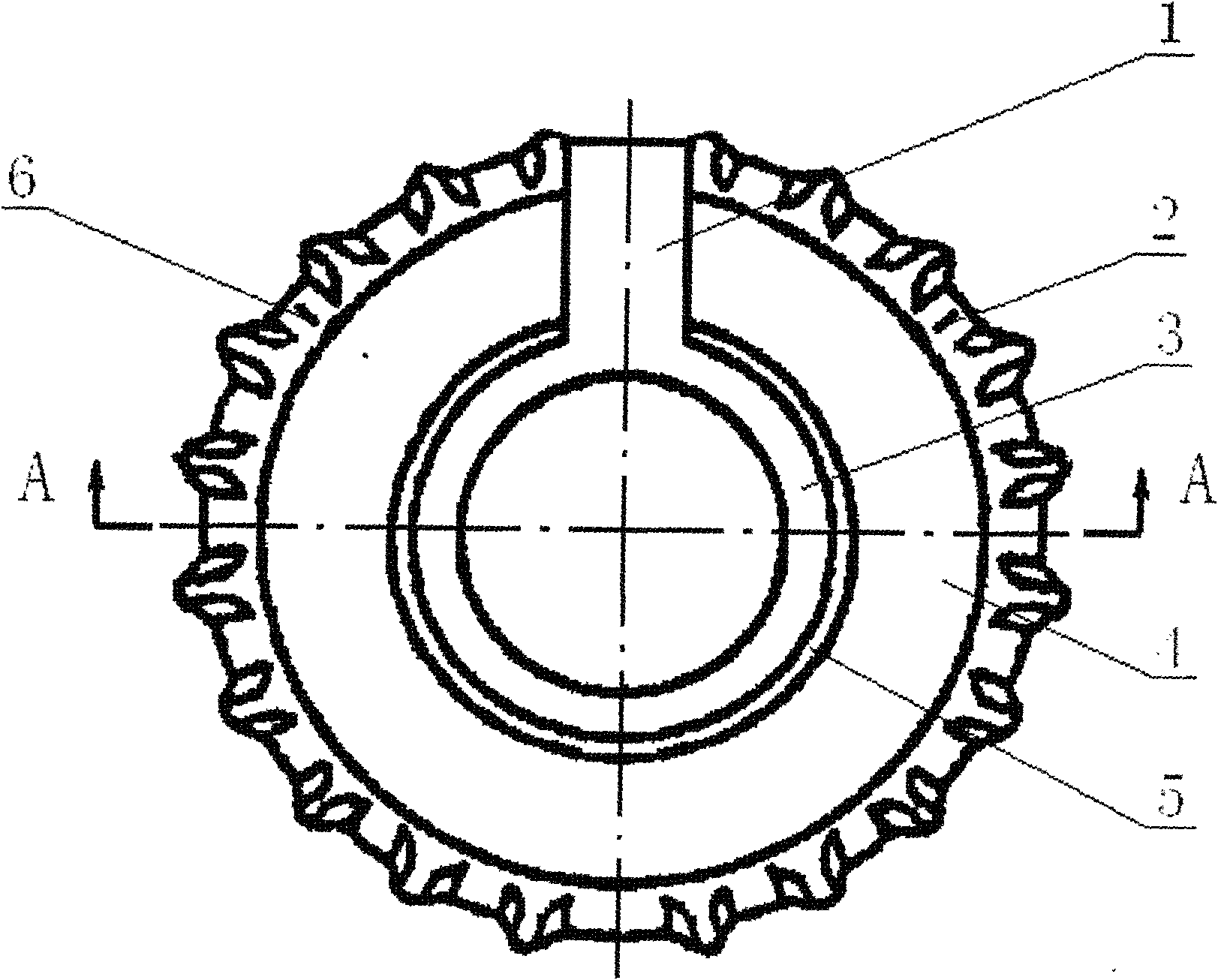

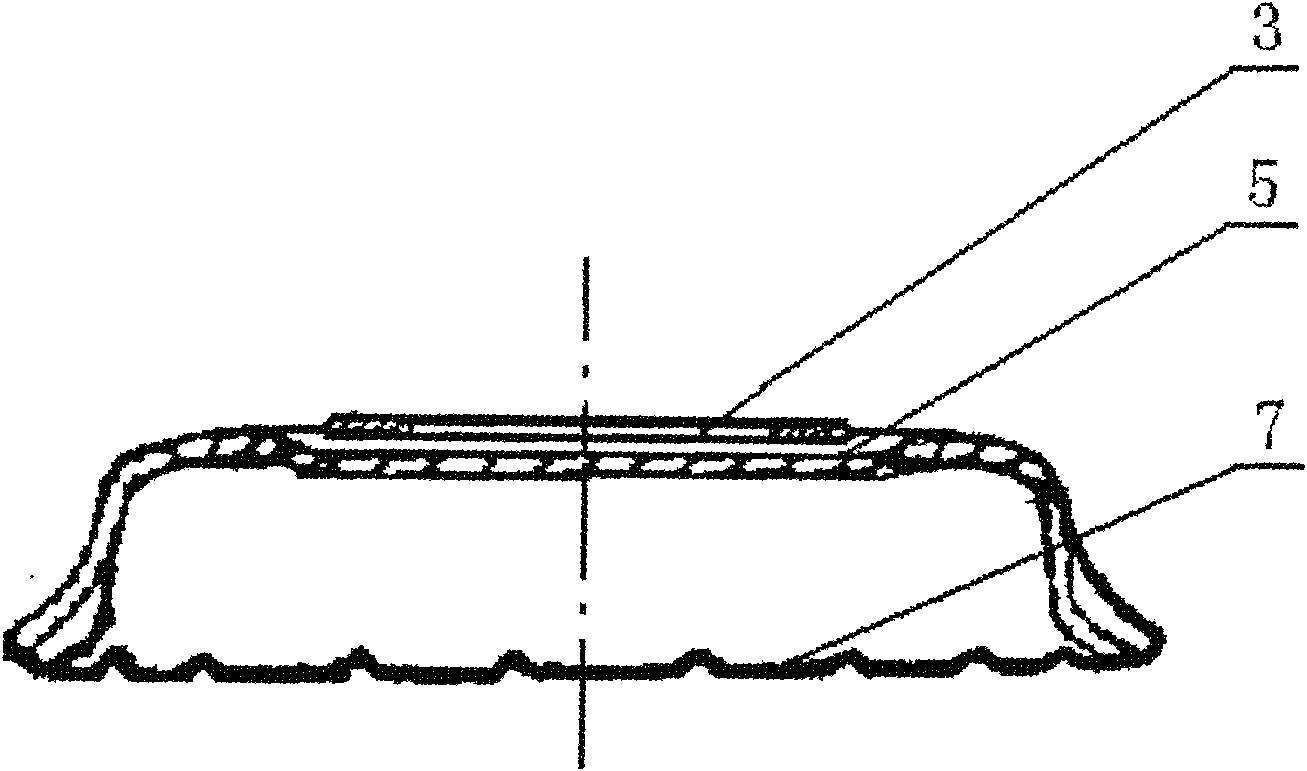

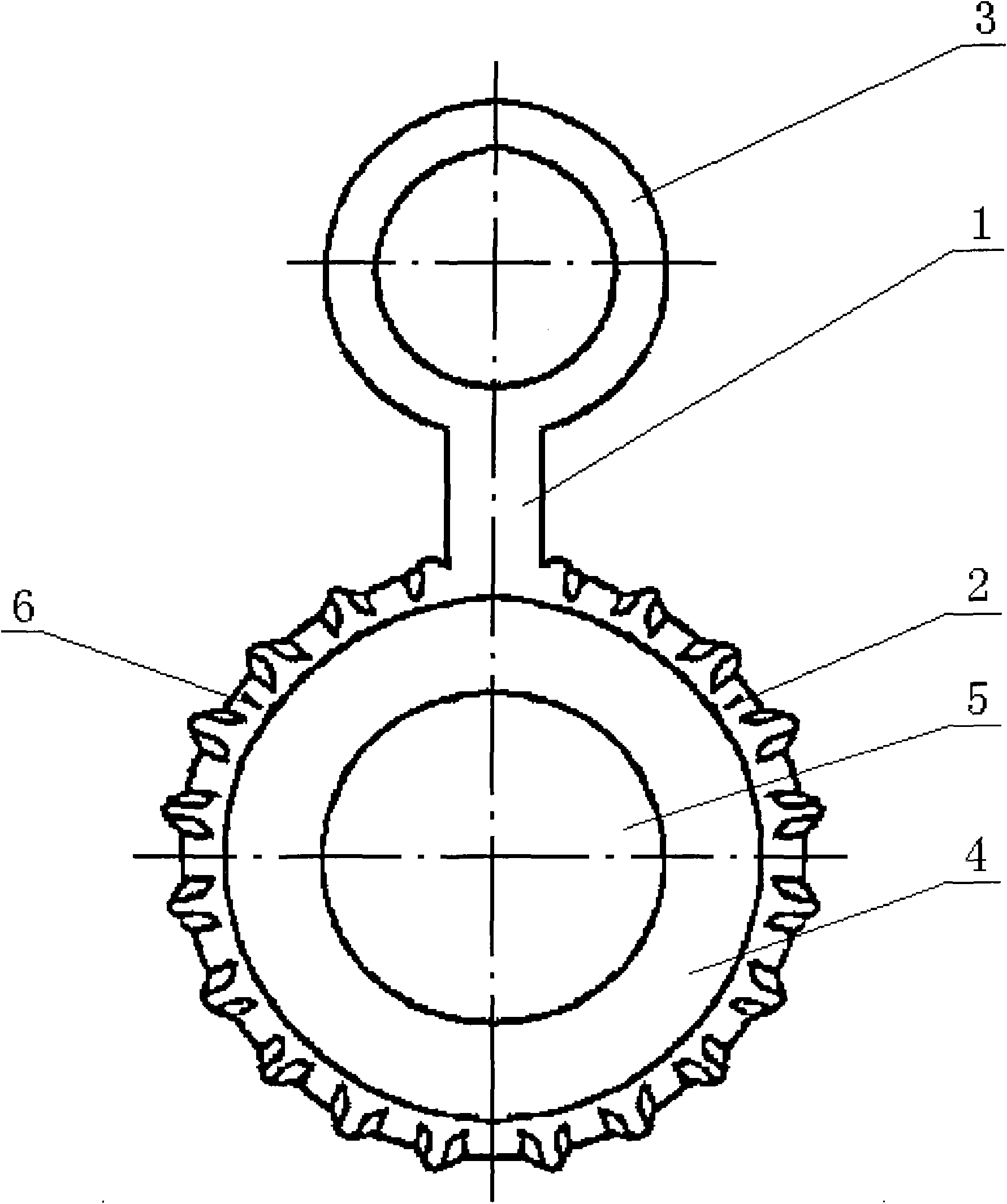

[0019] Such as figure 1 , figure 2 , image 3 As shown, the cap body 4 of the easy-open crown-shaped bottle cap is made up of a bottle cap top and a bottle cap side. There is a circular concave cavity 5 in the center of the top of the bottle cap, and a connecting strip 1 with a handle extends from the bottom edge 7 of the side of the bottle cap. The connecting strip 1 on the side of the bottle cap is symmetrically provided with a first longitudinal incision 2 and a second incision on both sides. 6. The first cutout 2 and the second cutout 6 are located between the side bottom edge 7 of the bottle cap and the top of the bottle cap. The length of the first slit 2 and the second slit 6 is 3 to 6 millimeters, and the interval between the first slit 2 and the bottom edge 7 of the bottle cap side and the interval between the second slit 6 and the bottom edge 7 of the bottle cap are 0.4 to 2 mm. mm, different intervals are adopted according to the material of the crown-shaped bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com