Discharge structure of glass kiln

A glass furnace and forehearth technology, applied in inorganic chemistry, non-metallic elements, halogen/halogen acid, etc., can solve the problems of large flow, uncontrollable flow, increased flow, etc., achieving simple operation, favorable promotion, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

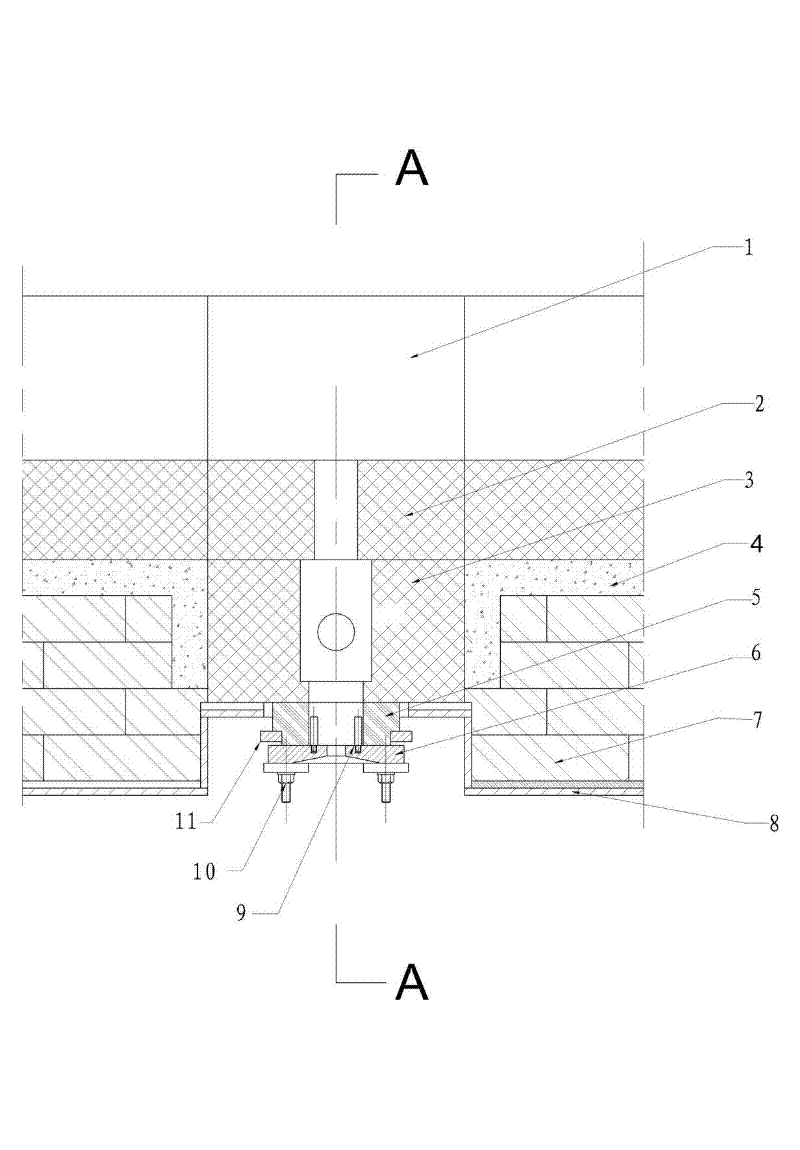

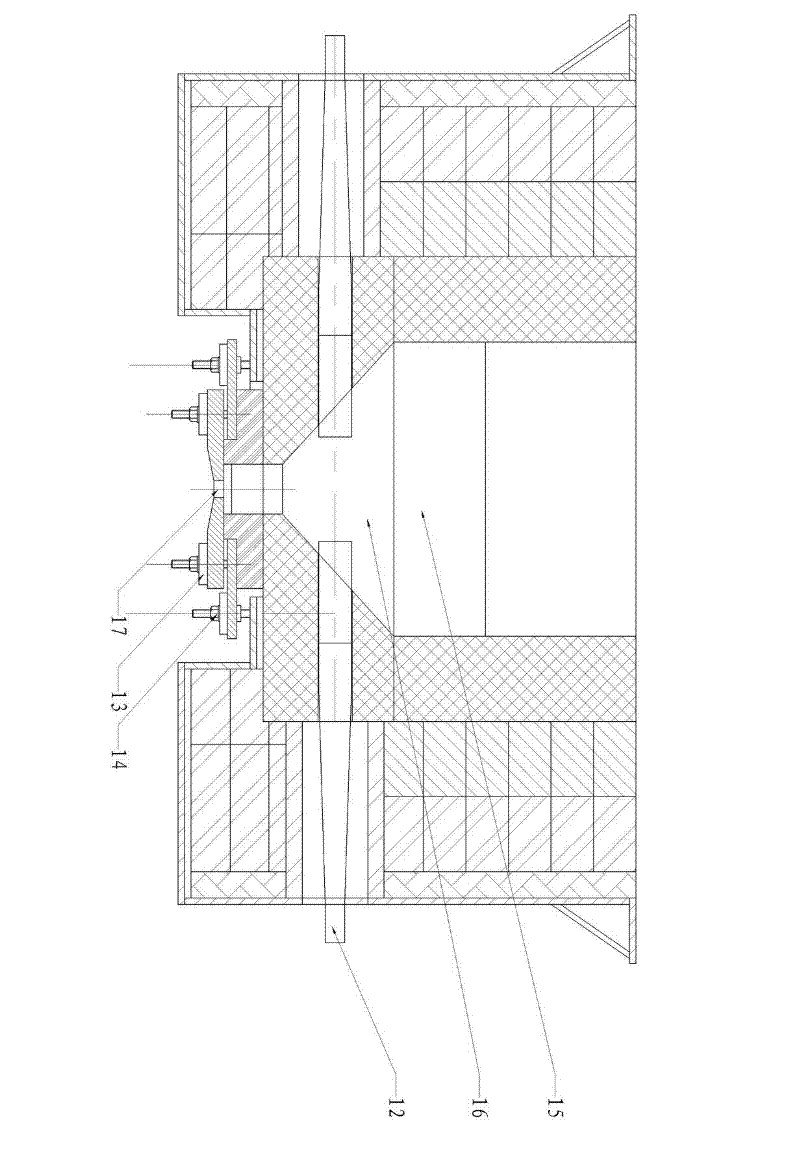

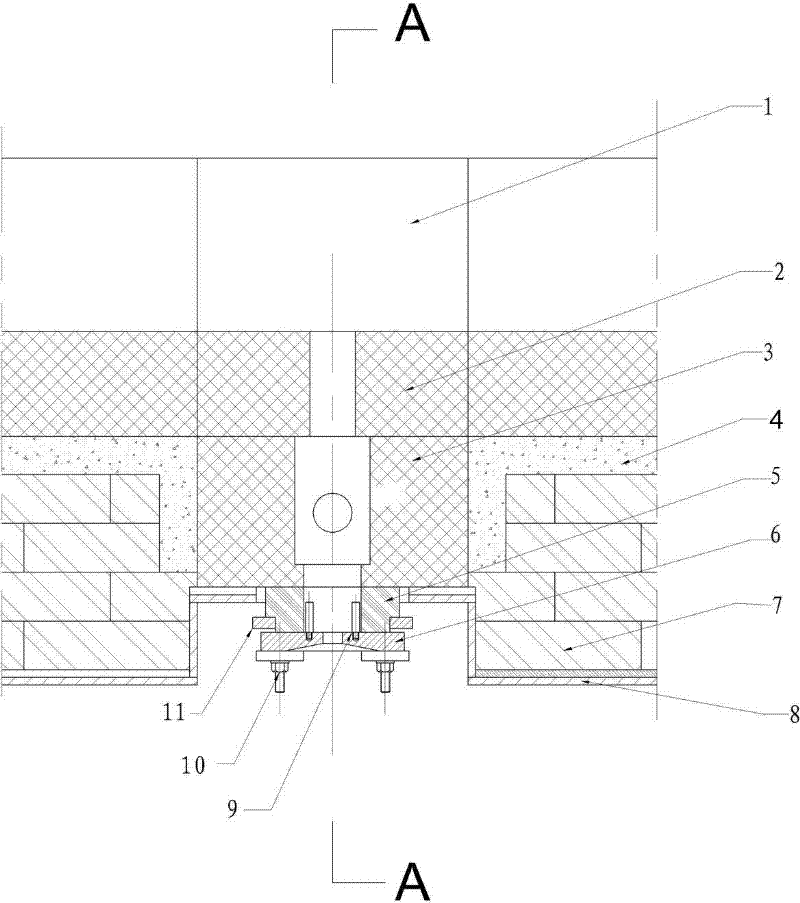

[0022] Reference attached figure 1 , 2 , a glass kiln discharging structure, the glass kiln includes a forehearth shell 8 with a discharge hole at the bottom, a forehearth 1 inside the forehearth shell 8 and a clay at the bottom of the forehearth shell 8 Brick 7, the discharge structure of the glass kiln is a cuboid structure as a whole, which includes the discharge bottom brick 2, discharge brick 3, spacer brick 5, connecting Plate 11 and heat-resistant orifice plate 6; the discharge bottom brick 2, discharge brick 3 and heat-resistant orifice plate 6 are respectively provided with a first blanking part 15, a second blanking part 16 and a third blanking part Molybdenum electrodes 12 are installed on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com