Tunnel construction method based on steel tube arch-rib supporting structure

A technology of steel tube arch rib and support structure, which is applied in tunnels, tunnel lining, earth-moving drilling, etc., can solve the problems of expensive construction equipment, cannot be widely used, cannot be reused, etc., and achieves short construction period and saves construction costs. , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

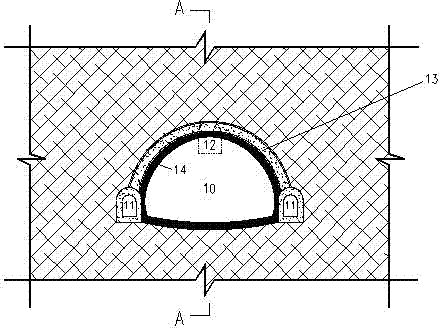

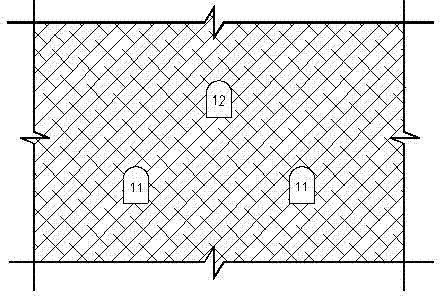

[0018] (1) if image 3 As shown, during construction, along the tunneling direction of the tunnel 10 to be excavated, two smaller leading pilot pits 11 are constructed at the arch feet, and a central pilot pit 12 is constructed at the vault top.

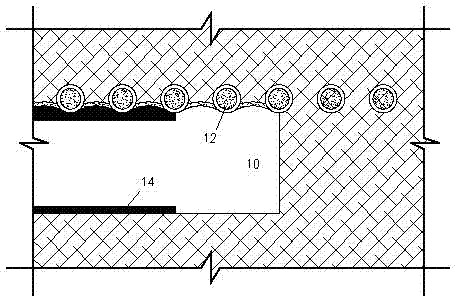

[0019] (2) Excavate circumferentially spaced arc-shaped pilot pits from the central pilot pit along multiple longitudinal working faces; lower the steel pipes in the arc-shaped pilot pits, and fill the steel pipes with concrete to form such Figure 4 The shown high-strength, high-capacity concrete-filled steel tube arch-rib support structure 13 .

[0020] (3) if Figure 5 As shown, the main tunnel 10 is excavated under the protection of the previously formed steel tube concrete arch rib support structure 13 . Arc grid arch support is used between the circumferential arch ribs, the longitudinal section is as follows Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com