End cover, valve body matched therewith, main valve of four-way reversing valve, and four-way reversing valve

A four-way reversing valve and matching technology, applied in the direction of valve details, multi-way valves, safety valves, etc., can solve the problems of welding gaps affecting welding quality, etc., and achieve the effect of avoiding low welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0030] The orientation words involved in this article, such as up, down, left, right, outside and inside, are defined based on the pictorial position of the four-way reversing valve in the attached drawing. It should be understood that the orientation words used in this article should not be limited. protection scope of this patent.

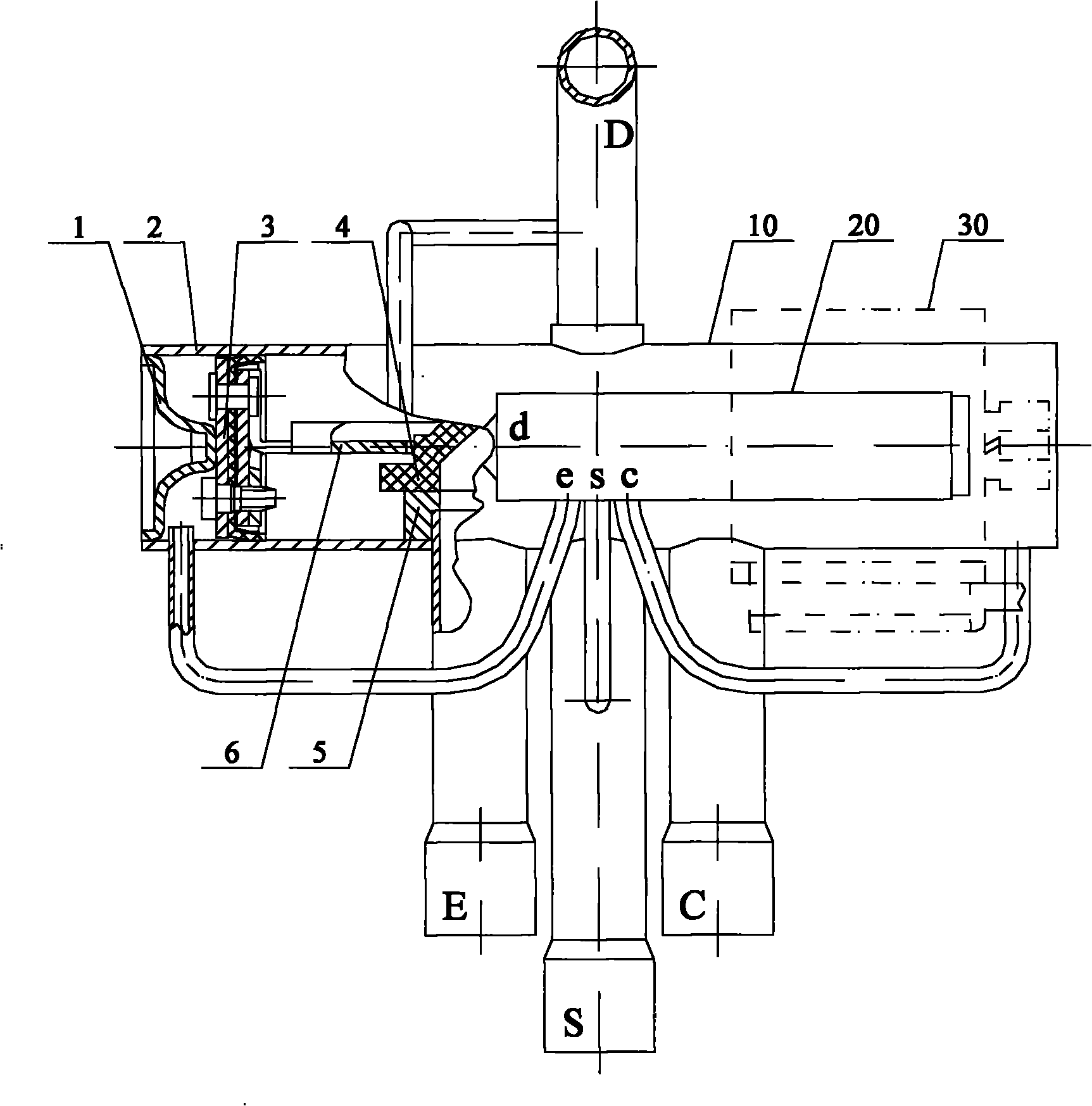

[0031] see image 3 . This figure is a schematic diagram of the overall structure of the four-way reversing valve described in this embodiment.

[0032] Such as image 3 As shown, the four-way reversing valve in this embodiment is mainly composed of a main valve 10 , a pilot valve 20 and an electromagnetic coil 30 .

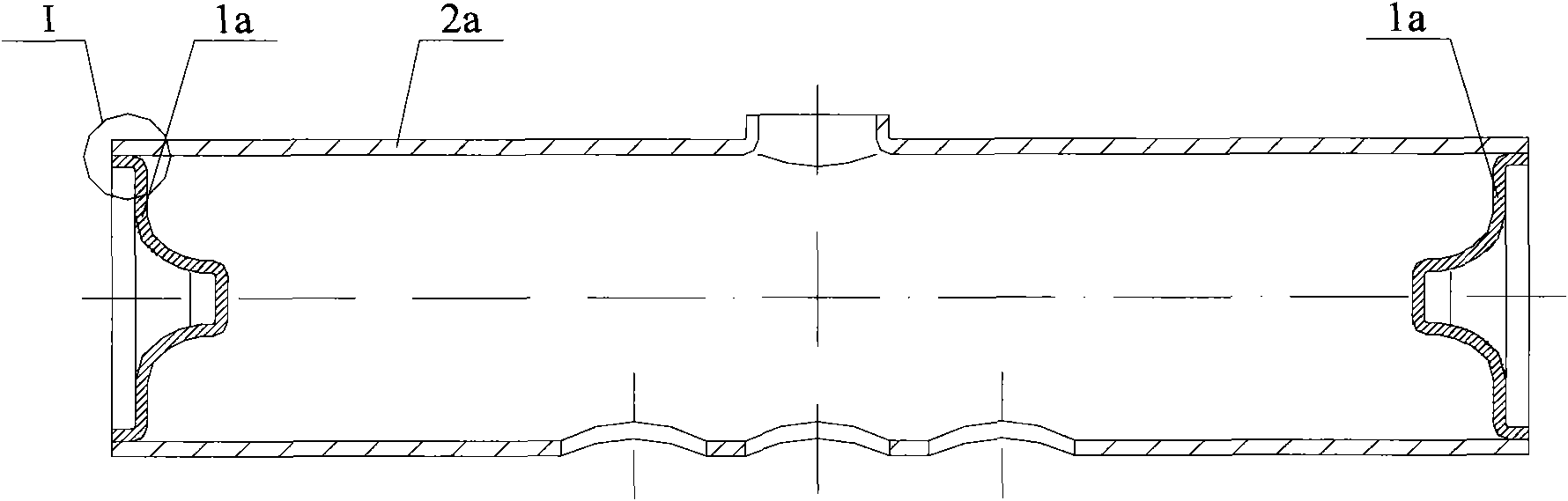

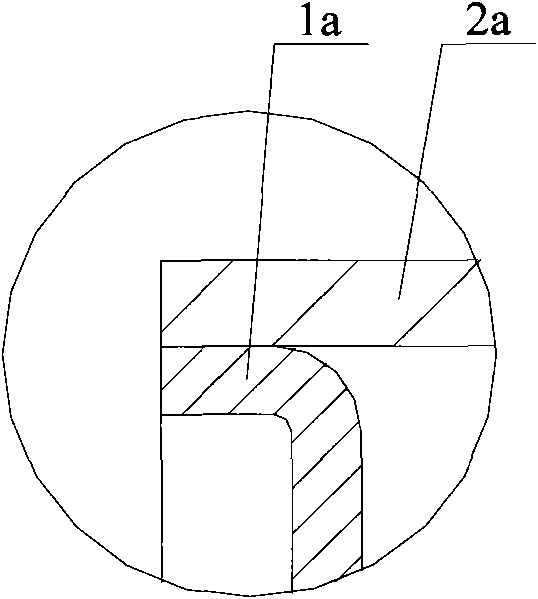

[0033] The main valve 10 of the four-way reversing valve is mainly composed of a valve body 2, an end cover 1 sealed and connected to both sides of the valve body, a valve seat 5 fixedly arranged in the inner cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com