Bonding equipment

一种贴合设备、贴合装置的技术,应用在仪器、化学仪器和方法、电气元件等方向,能够解决影响设备利用率贴合的效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The laminating equipment provided by the present invention will be described in further detail below in conjunction with the drawings and embodiments.

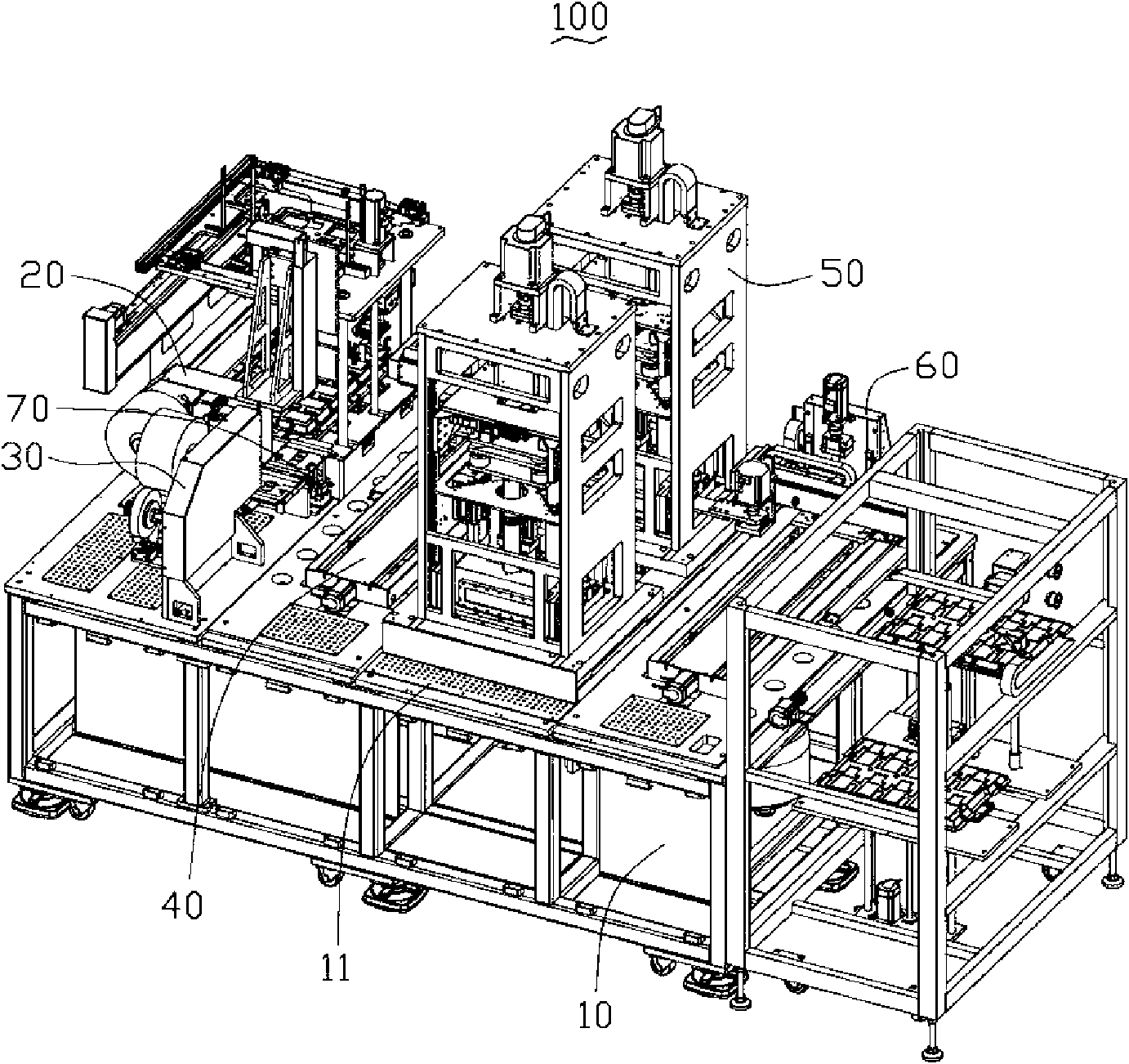

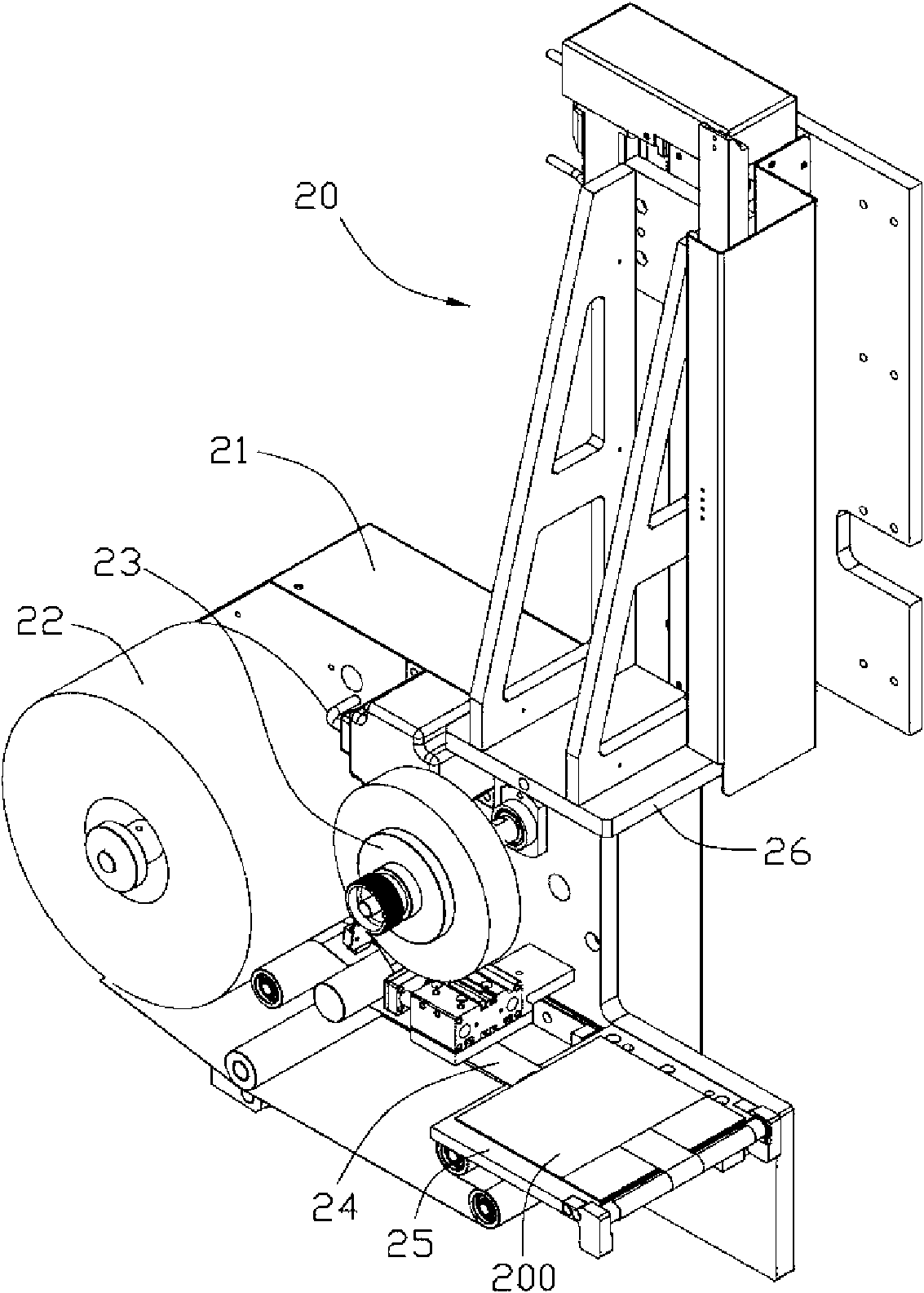

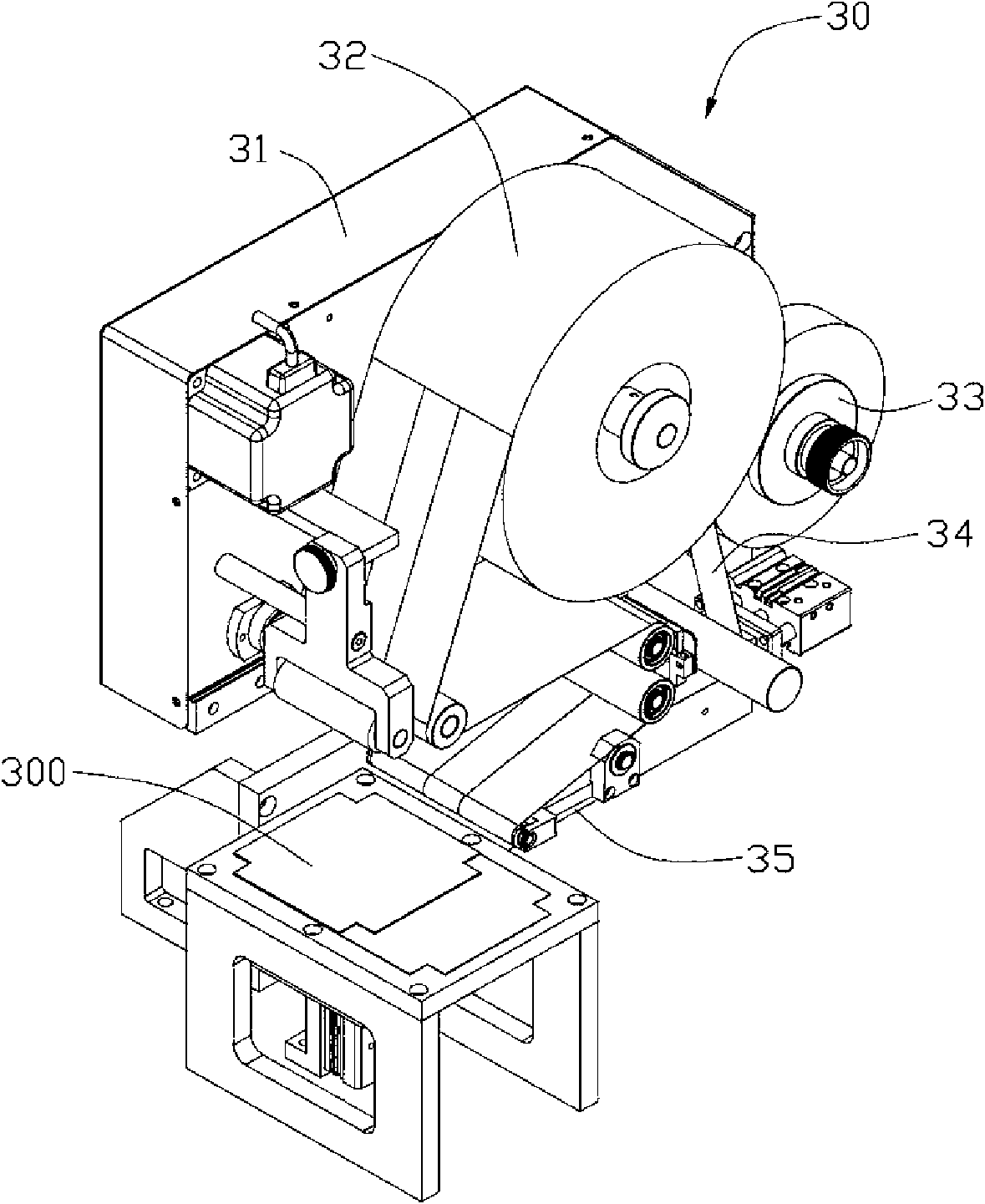

[0017] See figure 1 , The laminating device 100 provided by the embodiment of the present invention is used for the first substrate 200 (such as figure 2 Shown) and the second substrate 300 (as image 3 Shown) for bonding. The laminating equipment 100 includes a base 10, a first tearing device 20 fixed on the base 10, a second tearing device 30, a feeding mechanism 40, at least two vacuum laminating devices 50, an unloading mechanism 60, and positioning Agency 70. The feeding mechanism 40 and the unloading mechanism 60 are respectively located on opposite sides of the vacuum laminating device 50.

[0018] See also figure 2 with image 3 The first substrate 200 and the second substrate 300 may be glass plates used to manufacture touch panels and liquid crystal displays, or may be components used to manufacture devices such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com