Arc plate-shaped display module, manufacturing method thereof and used manufacturing device

A manufacturing method and display module technology, applied in the field of manufacturing devices, can solve problems such as difficult control of display panel production yield, damage or wear, and display panel 10 arc changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

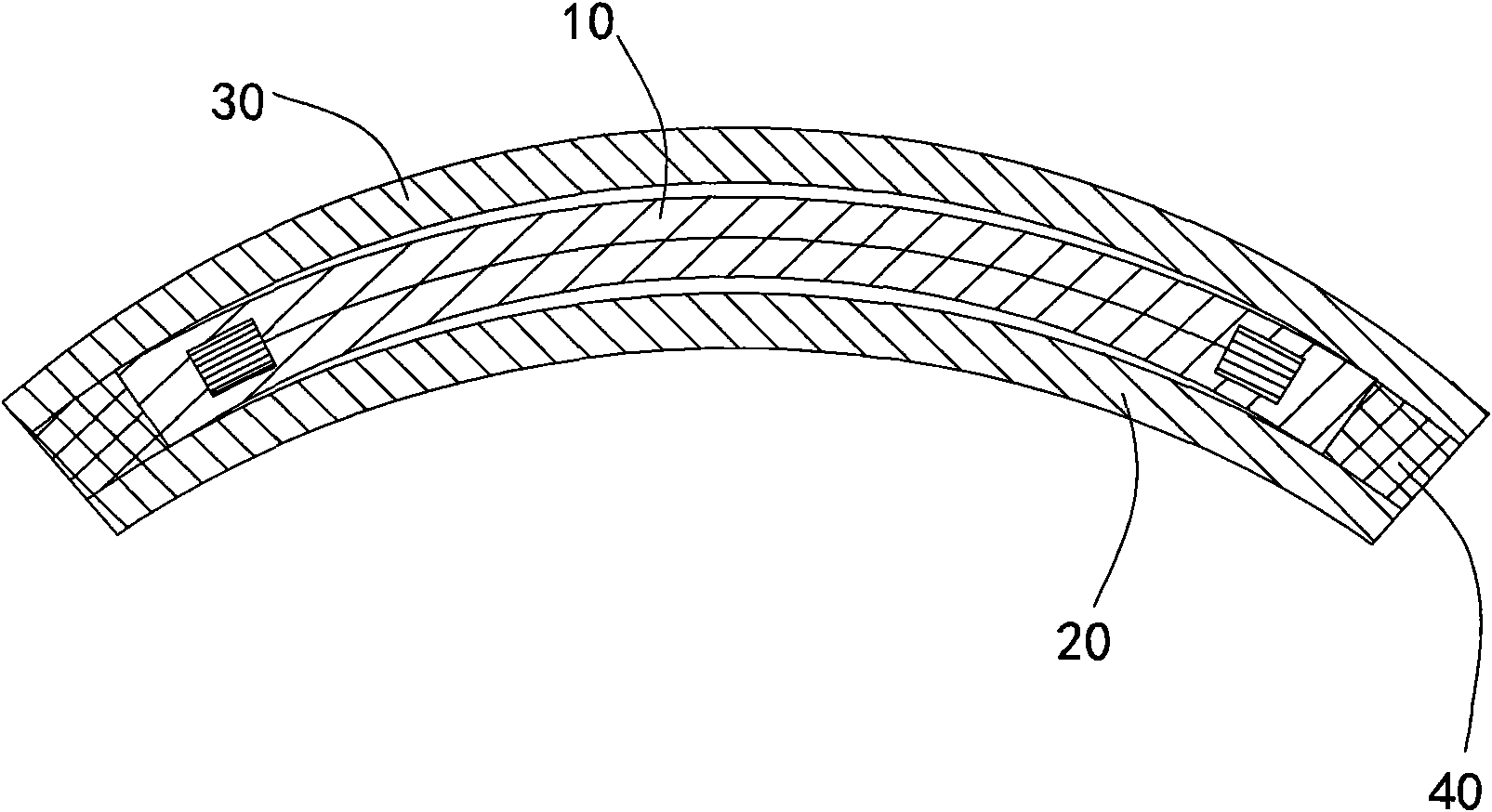

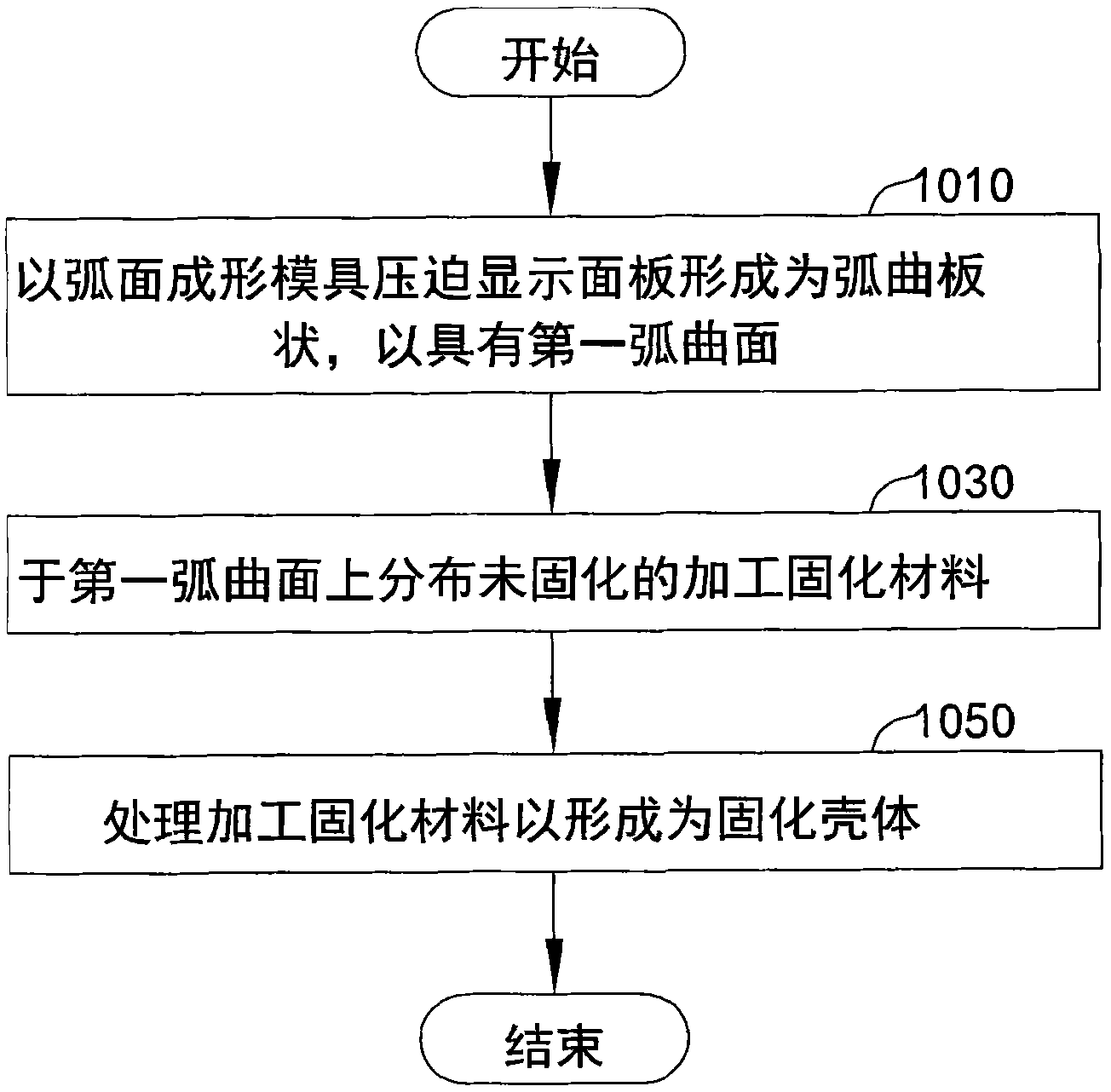

[0069] The invention provides a display module with a curved plate shape, a manufacturing method thereof and a manufacturing device used in the manufacturing method. The display module is manufactured by processing a display panel; in a preferred embodiment, the display panel preferably includes a liquid crystal display device, an organic light emitting diode display device, an electrophoretic display device or other flexible flat display devices. The present invention maintains the shape of the display module after bending by using process-cured material. The processing and curing material is preferably light-curing resin, thermosetting resin, self-drying resin or other transparent or opaque processing materials.

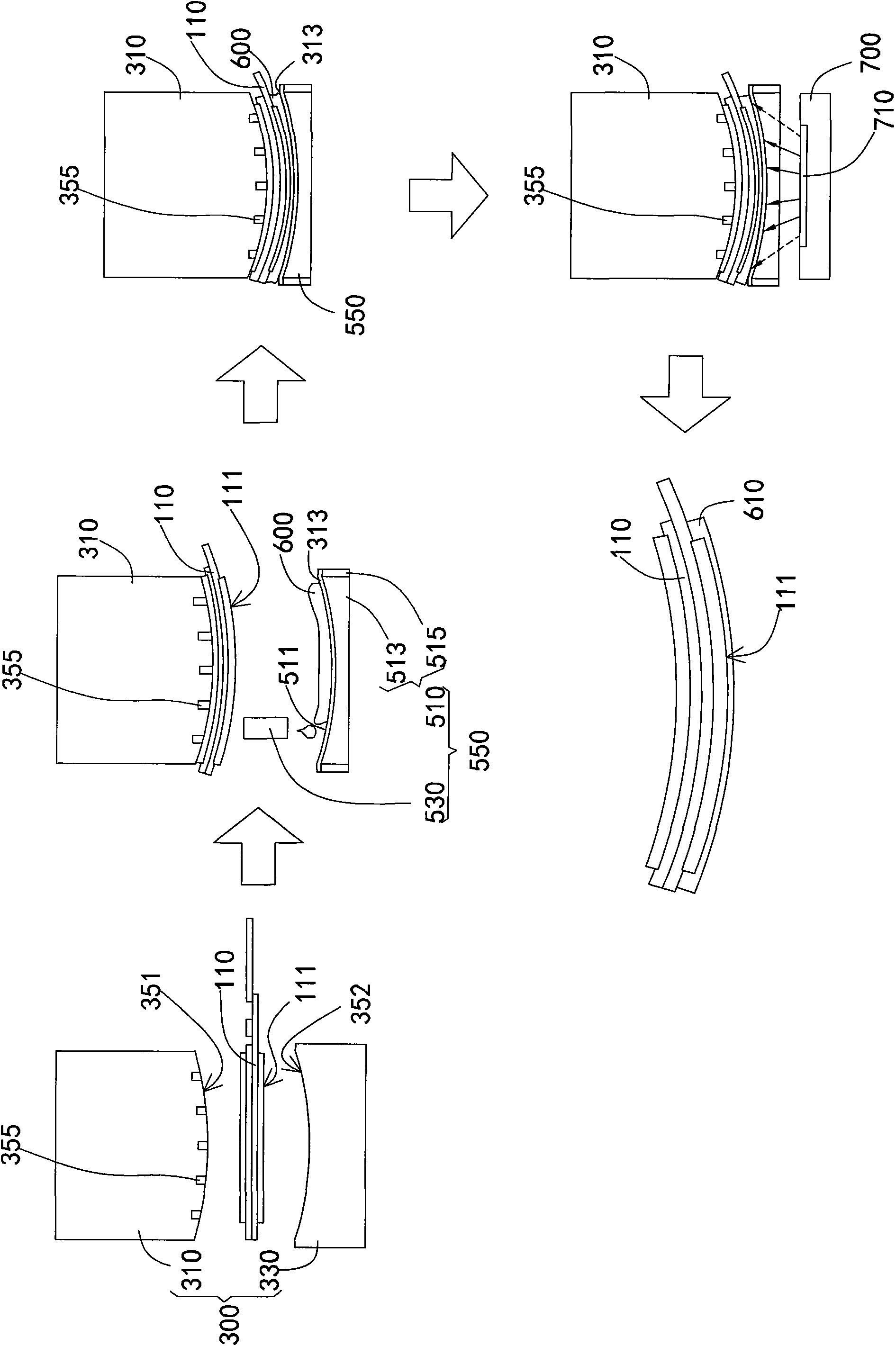

[0070] exist figure 2 In the illustrated embodiment, the display module manufacturing device mainly includes a curved surface forming mold 300 , a processing and curing material distribution device 500 and a processing and curing device 700 . The curved surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com