Socket with integrated connected plug bush

An integrated, plug-in technology, applied in the direction of connection, contact parts, electrical components, etc., can solve the problems of large occupied size, false welding and false welding, large occupied space, etc., to achieve small occupied space, reduced area, and reasonable distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

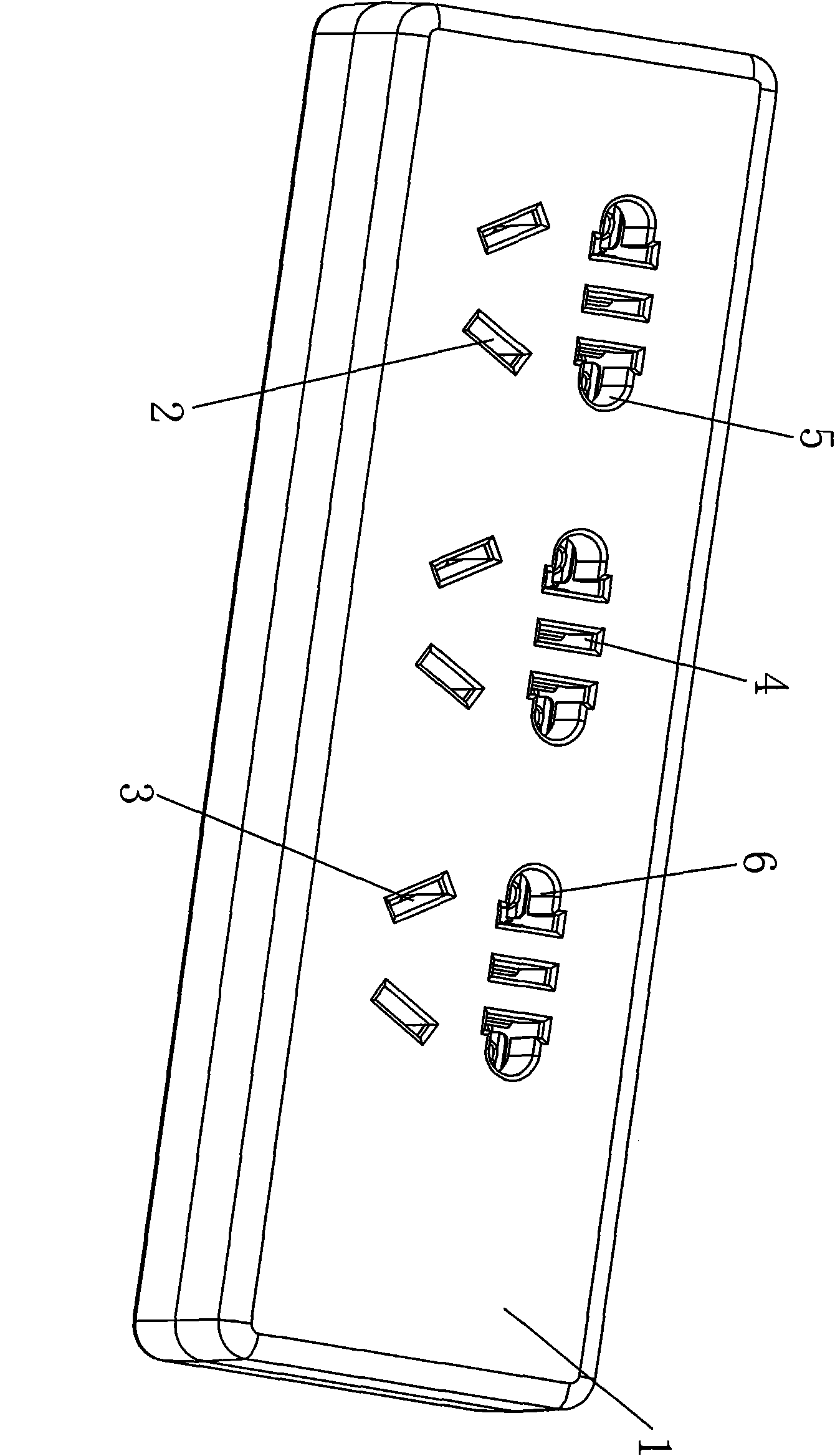

[0020] refer to figure 1 , figure 2 , a socket with an integrated one-piece socket, including a housing 1, the housing 1 is provided with jacks, and the jacks include a three-pole L-level jack 2 and a three-pole N-level jack 3. E-level jack 4, and two-pole L-level jack 5 and two-pole N-level jack 6, the E-level jack 4 is located between the two-pole L-level jack 5 and the two-pole N-level jack 6 .

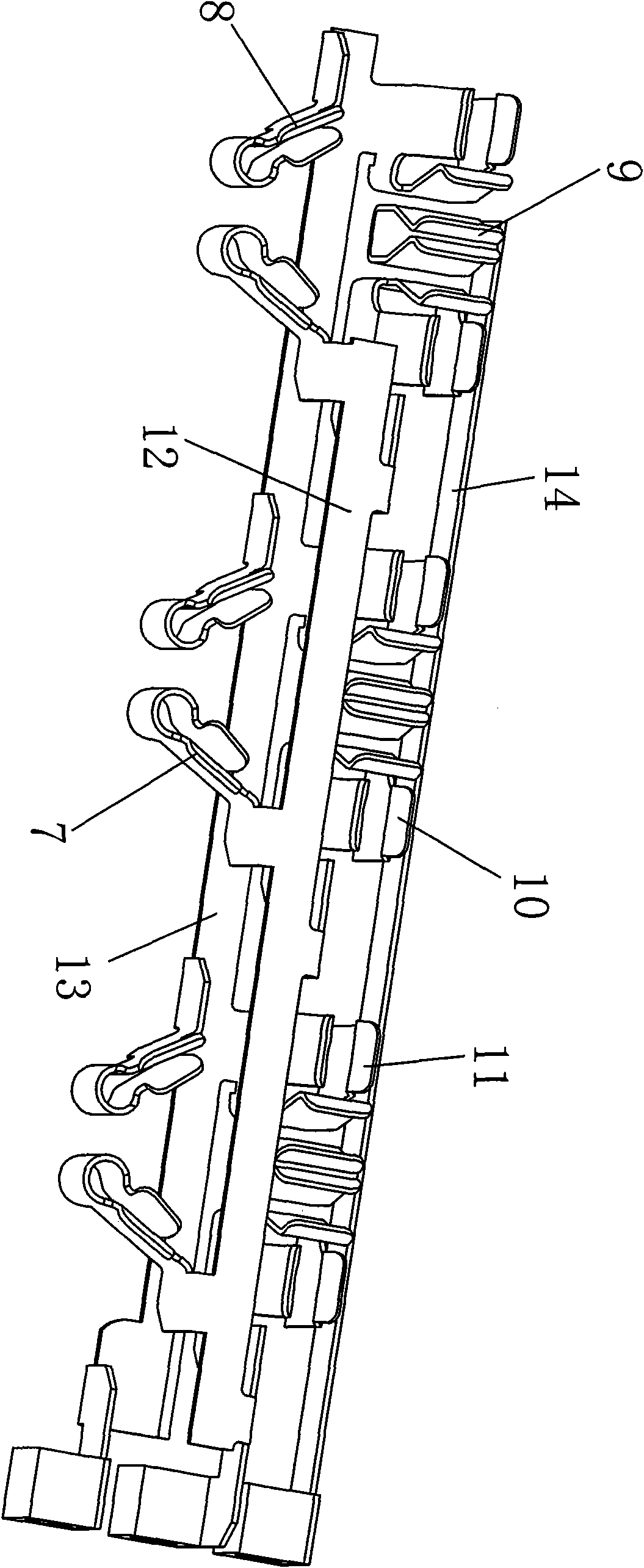

[0021] The housing 1 is provided with a three-pole L-level socket 7 corresponding to the three-pole L-level socket 2 and a three-pole N-level socket 8 corresponding to the three-pole N-level socket 3 , the E-level socket 9 corresponding to the E-level socket 4, the two-pole L-level socket 10 corresponding to the two-pole L-level socket 5, and the two-pole N-level socket 6 corresponding to the two poles N-level socket 11.

[0022] All the three-pole L-level sockets 7 and the two-pole L-level sockets 10 are connected by L-level copper strips 12 into an integrated structure: the ...

Embodiment 2

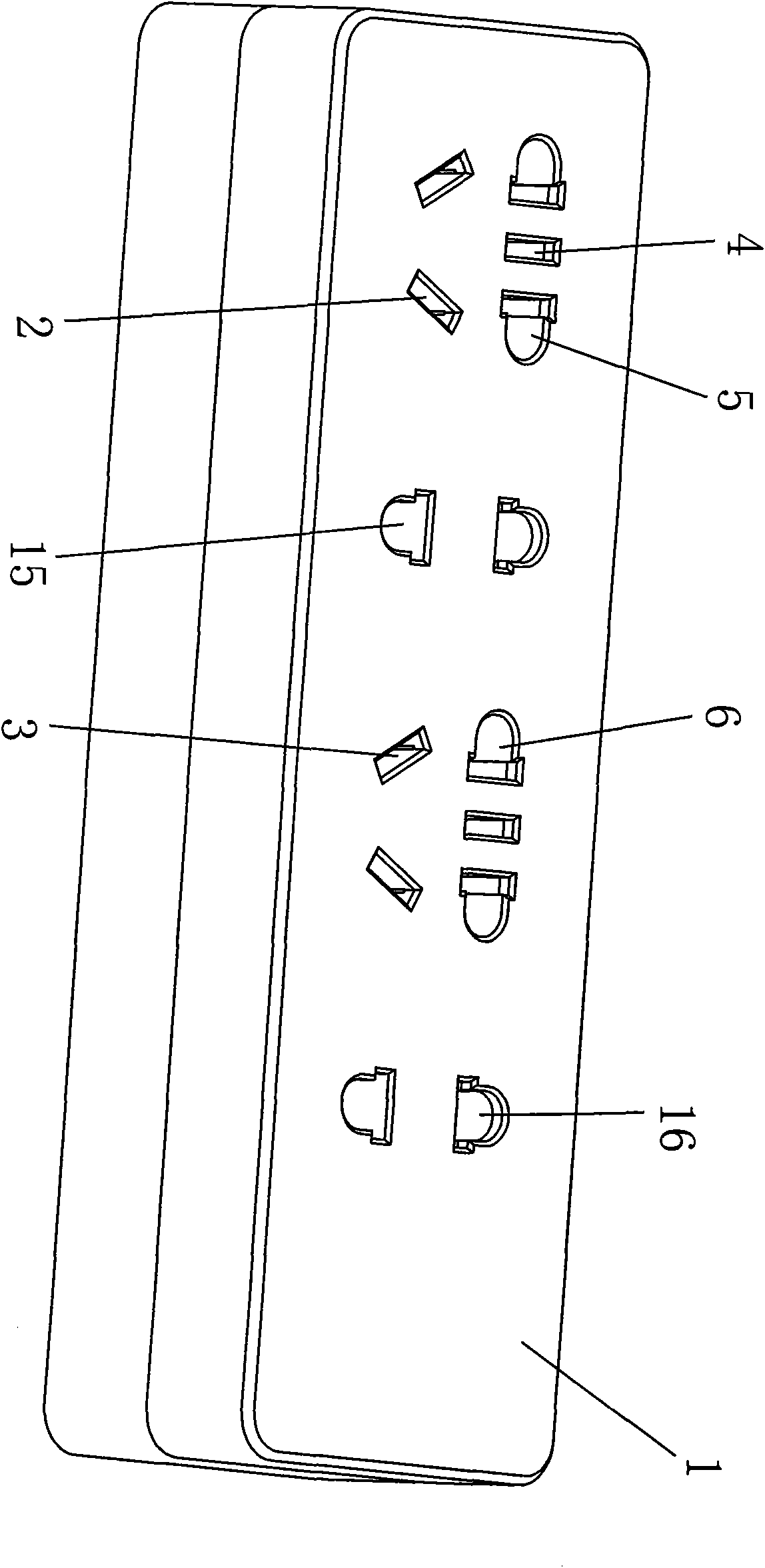

[0027] refer to image 3 , Figure 4 , a socket with an integrated one-piece socket, including a housing 1, the housing 1 is provided with jacks, and the jacks include a three-pole L-level jack 2 and a three-pole N-level jack 3. An E-level jack 4, and a bipolar L-level jack 5 and a bipolar N-level jack 6, the E-level jack is located between the bipolar L-level jack and the bipolar N-level jack.

[0028] The casing 1 is also provided with an independent two-pole L-level jack 15 and an independent two-pole N-level jack 16 .

[0029] The housing 1 is provided with a three-pole L-level socket 7 corresponding to the three-pole L-level socket 2 and a three-pole N-level socket 8 corresponding to the three-pole N-level socket 3 , the E-level socket 9 corresponding to the E-level socket 4, the two-pole L-level socket 10 corresponding to the two-pole L-level socket 5, and the two-pole N-level socket 6 corresponding to the two poles N-level socket 11.

[0030] The housing 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com