Mold release film

A release film and curing technology, which is applied in the direction of electrical components, circuits, layered products, etc., can solve the problems of poor air exposure due to transfer, different material expansion and contraction, and reduced productivity, and achieve air exposure resistance and Excellent non-transferability, high industrial value, excellent retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

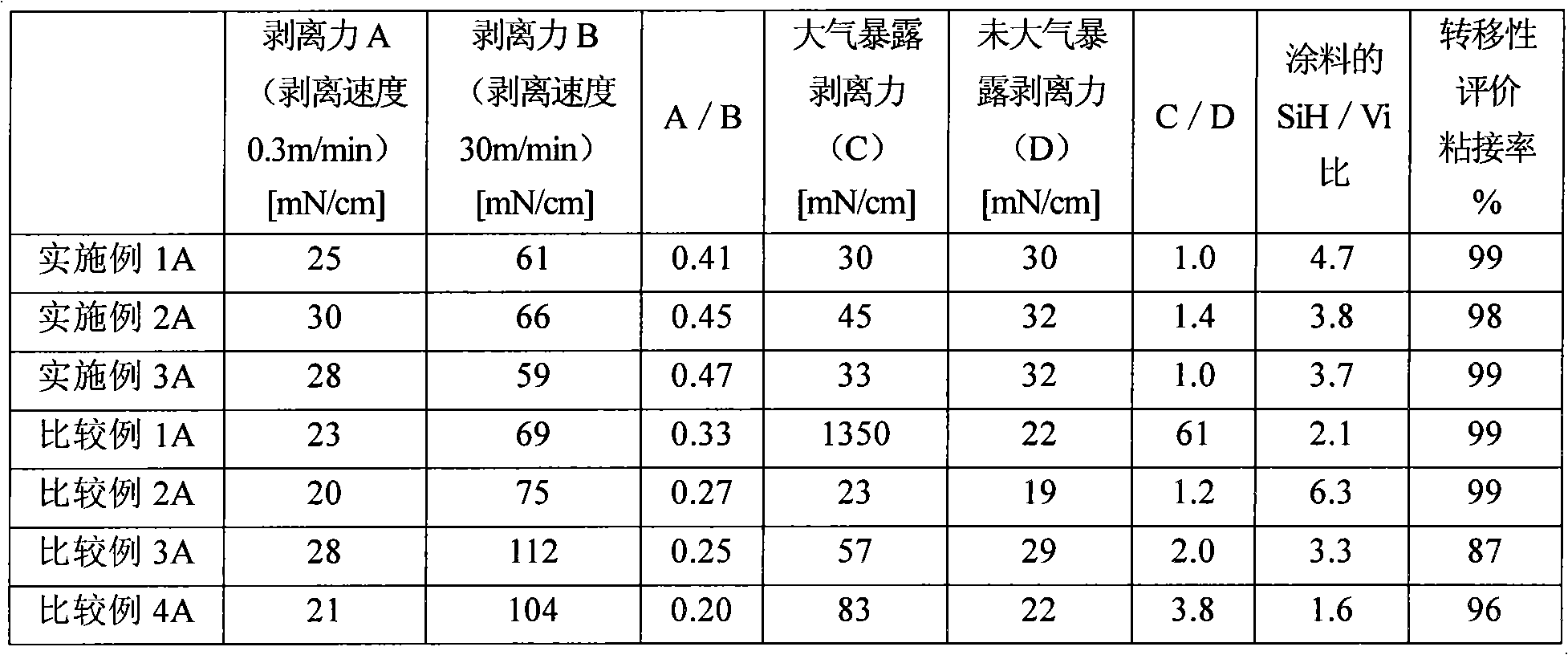

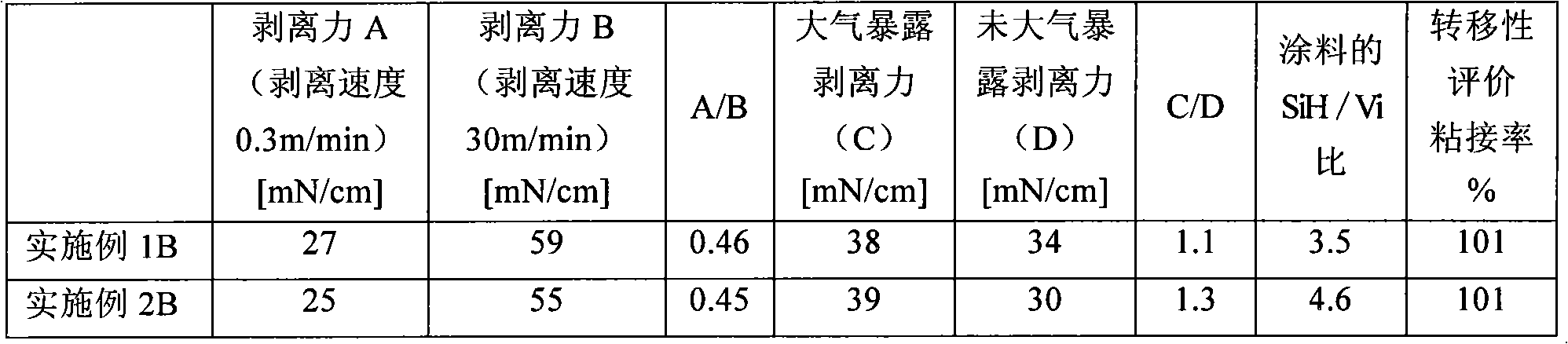

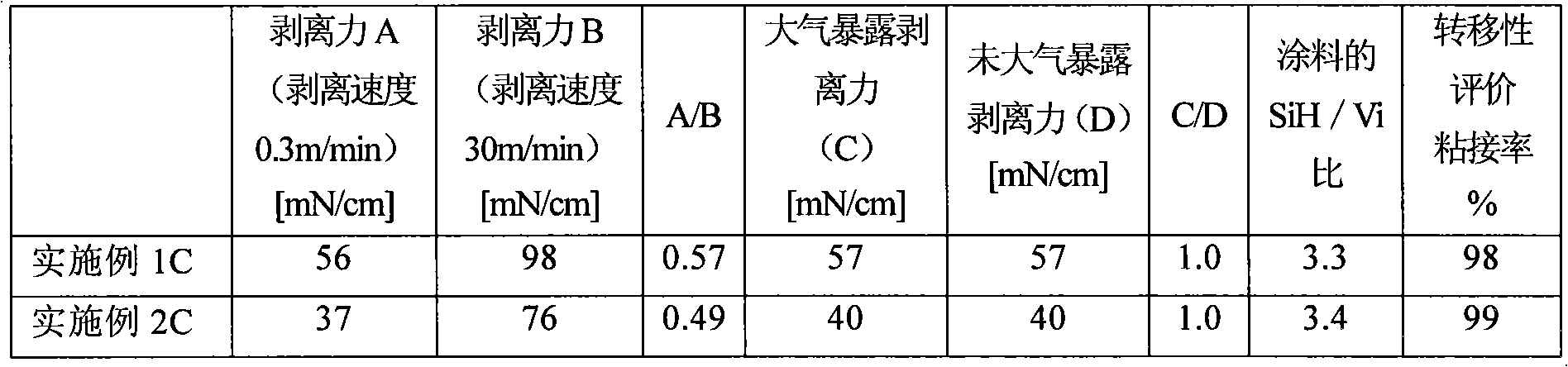

Examples

Embodiment 1A

[0071] On a 38 μm thick biaxially stretched PET film (manufactured by Mitsubishi Chemical Polyester Film Co., Ltd.: Diafoil T100-38), the coating weight (after drying) is about 0.12 (g / m 2 ) to apply a release agent comprising the following composition, and heat-treat at 150° C. for 10 seconds to obtain a release film.

[0072] "Release agent composition"

[0073] The following three components (i) to (iii) were diluted with a mixed solvent of toluene / MEK / isooctane (mixing ratio 1:1:1) to prepare a coating liquid having a solid content concentration of 2% by weight.

[0074] (i) The viscosity of a 30% toluene solution is 15,000 mPa·s, and a solvent-type silicone (manufactured by Shin-Etsu Chemical Co., Ltd.: KS-830, non-volatile) containing about 5% vinyl groups in terms of siloxane units in the main polymer Ingredient 30%)...100 parts by weight

[0075] (ii) with (CH 3 ) 3 SiO(-SiH(CH 3 )-O) m -Si(CH 3 ) 3 Indicated silicone (manufactured by Gelest: HMS-991, viscosity...

Embodiment 2A

[0078] Except having changed the release agent composition in Example 1A into the following release agent composition, it manufactured similarly to Example 1A, and obtained the release film.

[0079] "Release agent composition"

[0080] The following three components (i) to (iii) were diluted with a mixed solvent of toluene / MEK / isooctane (mixing ratio 1:1:1) to prepare a coating liquid having a solid content concentration of 2% by weight.

[0081] (i) The viscosity of a 30% toluene solution is 15,000 mPa·s, and a solvent-type silicone (manufactured by Shin-Etsu Chemical Co., Ltd.: KS-830, non-volatile) containing about 5% vinyl groups in terms of siloxane units in the main polymer Ingredient 30%)...100 parts by weight

[0082] (ii) with (CH 3 ) 3 SiO(-SiH(CH 3 )-O) m -Si(CH 3 ) 3 Indicated silicone (manufactured by Gelest: HMS-991, viscosity about 20mPa·s)...1 part by weight

[0083] (iii) Platinum-containing catalyst (manufactured by Shin-Etsu Chemical Co., Ltd.: catP...

Embodiment 3A

[0085] Except having changed the release agent composition in Example 1A into the following release agent composition, it manufactured similarly to Example 1A, and obtained the release film.

[0086] "Release agent composition"

[0087] The following three components (i) to (iii) were diluted with a mixed solvent of toluene / MEK / isooctane (mixing ratio 1:1:1) to prepare a coating liquid having a solid content concentration of 2% by weight.

[0088] (i) The viscosity of a 30% toluene solution is 8000 mPa·s, and the main polymer contains about 8% of vinyl groups in terms of siloxane units (Shin-Etsu Chemical Co., Ltd.: KS-3601, non-volatile Ingredient 30%)...100 parts by weight

[0089] (ii) with (CH 3 ) 3 SiO(-SiH(CH 3 )-O) m -Si(CH 3 ) 3 Indicated silicone (manufactured by Gelest: HMS-991, viscosity about 20mPa·s)...3 parts by weight

[0090] (iii) Platinum-containing catalyst (manufactured by Shin-Etsu Chemical Co., Ltd.: catPL-50T)...1 part by weight

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com