Tool and method for pressing injector copper sleeve of cylinder head

A technology for press-fitting tools and fuel injectors, which is applied to manufacturing tools, metal processing, hand-held tools, etc., can solve problems such as poor adaptability, crushed copper sleeves, and complicated operation, and achieves convenient operation, low cost and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

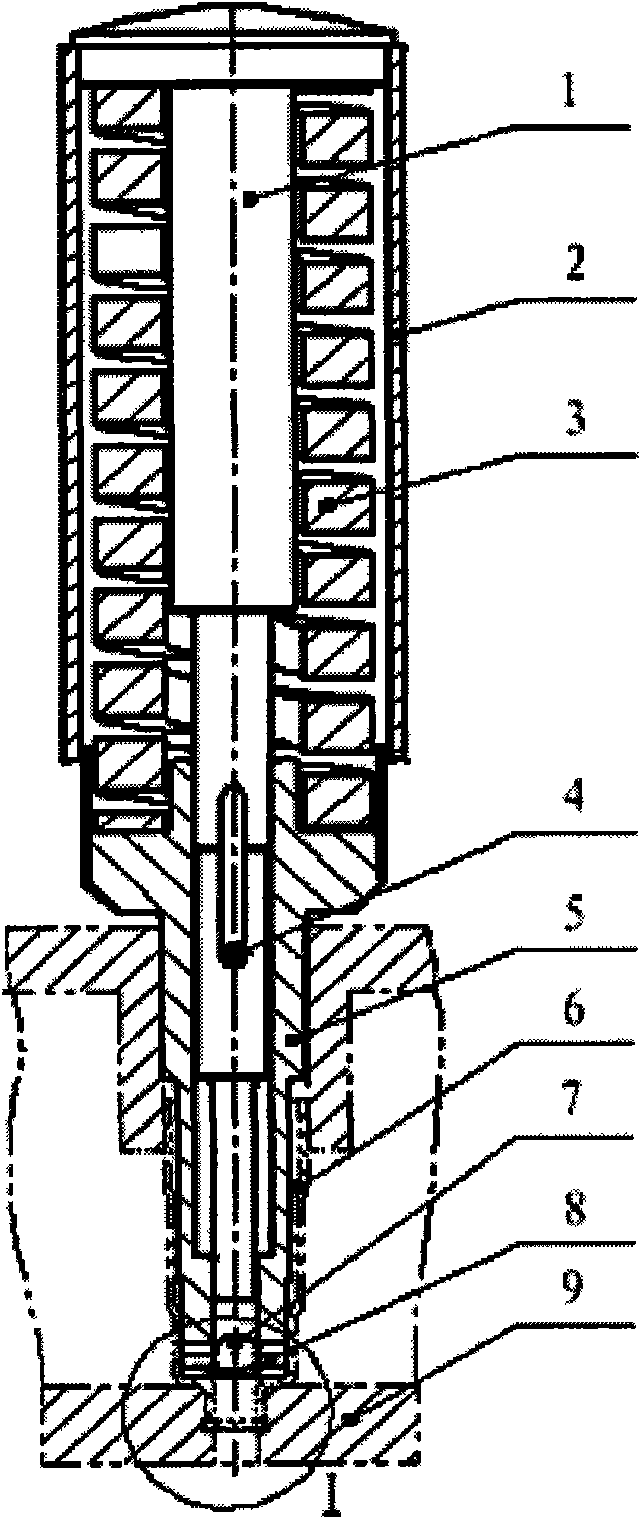

[0043] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention, such as the fixing method of the steel ball, the steel ball pressing rod Appropriate alternative structures can be adopted for the limit mode of the end pressure rod and the like.

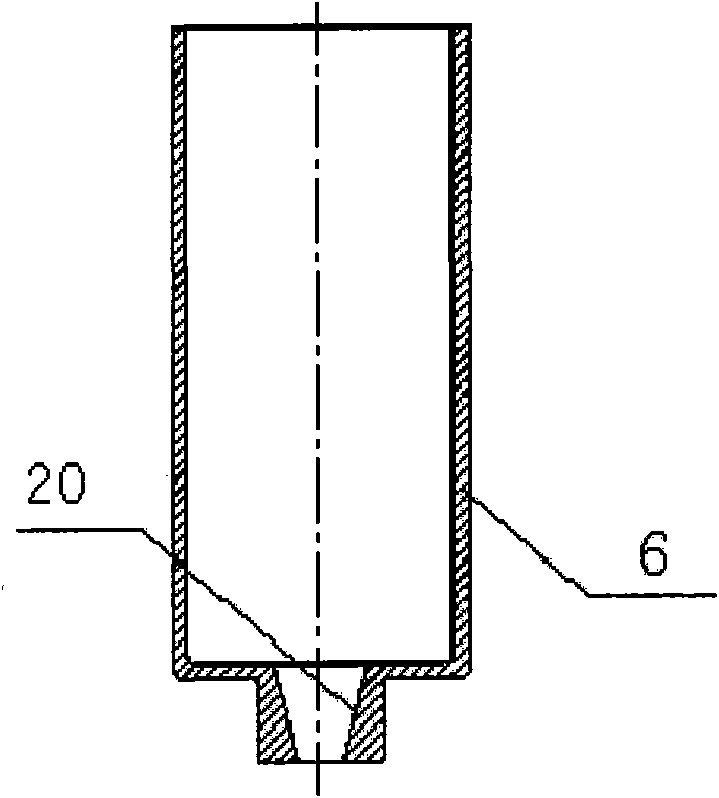

[0044] figure 1 It is a schematic diagram of the structure of the copper sleeve of the present invention before assembly. It is obvious from the figure that the copper sleeve 6 has a stepped surface and a tapered hole 20 . The inner step surface is just the surface to be pressed by the end pressure rod 5, and the tapered hole 20 is what the steel ball 7 will squeeze through.

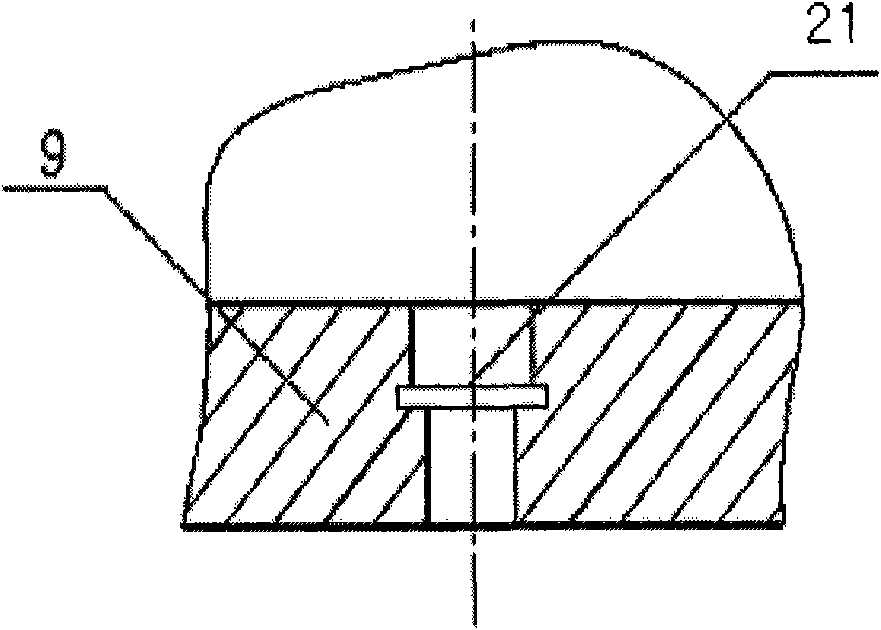

[0045] figure 2 It is a schematic diagram of the structure of the bottom hole of the cylinder head 9 fuel injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spring constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com