Doubling hot pack device of belted layer and doubling hot pack production process

A production process and belt layer technology, applied in the field of tire machinery, can solve the problems of poor flexibility and ductility of cold sheet, influence of tire quality, inability to complete, etc., and achieve the effects of improving production efficiency, improving production quality, and reducing the generation of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

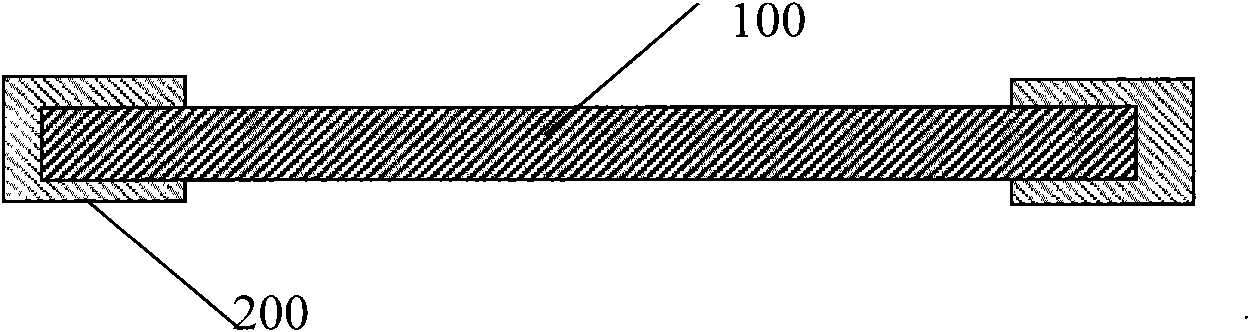

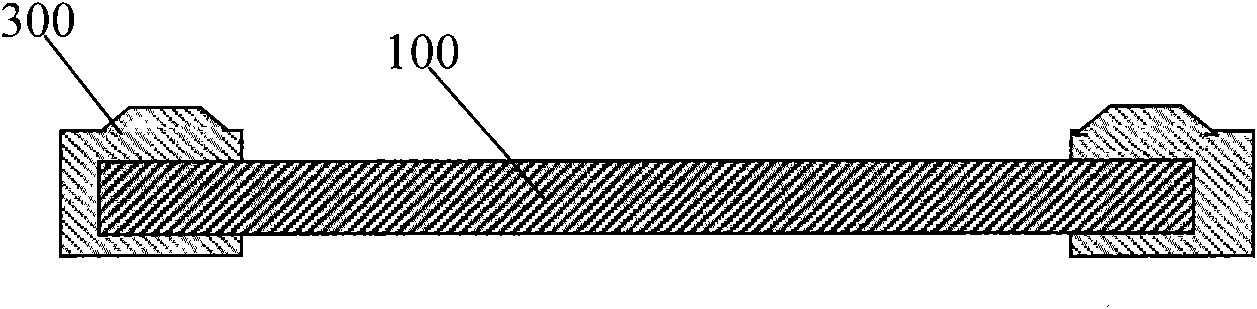

[0033] The present invention adopts off-line lamination and hemming, that is, after the production line is cut at a small angle, a specially designed belt lamination hot-wrapping device is used for hot-glue lamination and hemming of the belt.

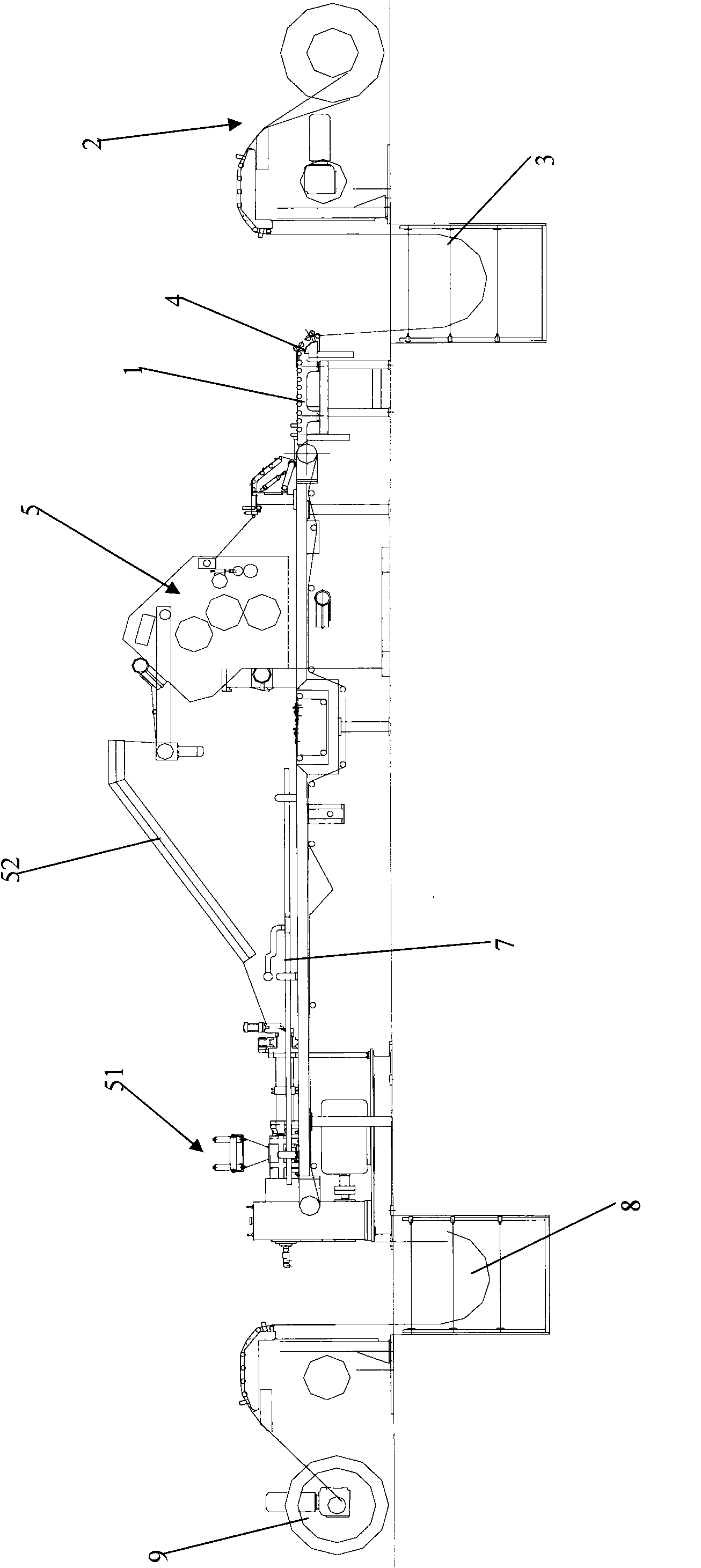

[0034] The belt sandwich glue hot-packing device of the present invention comprises: a laminating hemming conveyor belt 1, which is arranged at the end of the laminating hemming conveying belt 1 to guide the belt ply to the belt laminating hemming tape The guiding device 2 of the hemming conveyor belt 1; the centering device 4 arranged at the front end of the bonding hemming conveyor belt 1 adjacent to the guiding device 2; between the bonding hemming conveyor belt 1 and the guiding device 2 A storage device 3 for adjusting the speed of the two is provided; an extruder and a feeding device 51 and a calend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com