Wind-break wall of high speed railway

A technology for high-speed railways and windshields, applied to roads, protective equipment, tracks, etc., can solve problems that cannot be directly applied, and achieve the effects of simple and reasonable structure, good windshield effect, and simple installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

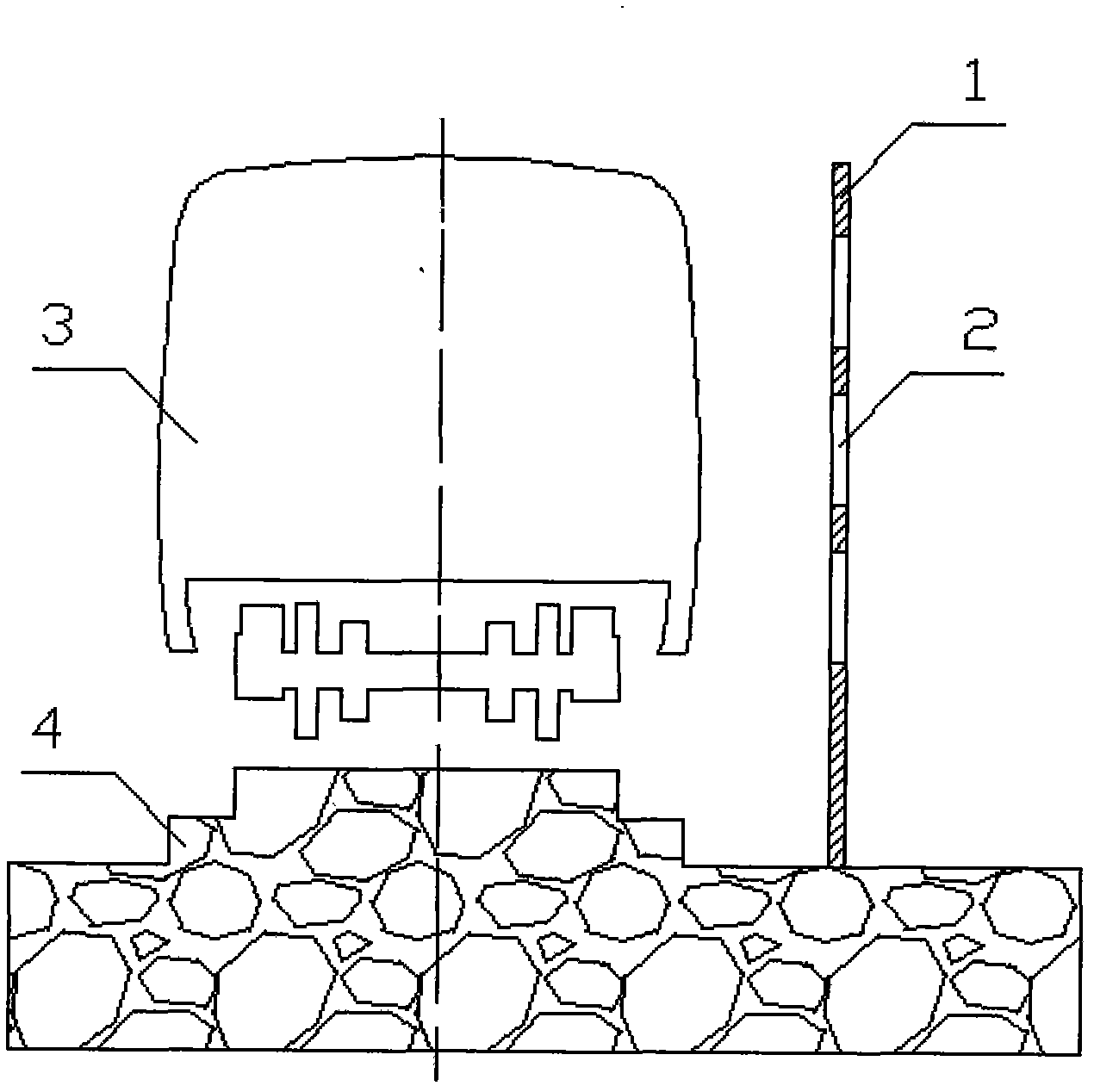

[0020] Embodiment 1: Straight plate structure.

[0021] The windshield wall 1 is installed on one side or both sides of the high-speed railway, and the windshield wall 1 is evenly distributed with circular ventilation holes 2 on the windward side wallboard. The edge of the side wall of the high-speed train body 3 is substantially flush; the lower edge of the wall panel of the windshield wall 1 is substantially flush with the lower edge of the high-speed train body underframe. The windshield 1 is a light metal plate beam structure.

[0022] The windshield wall 1 of the straight plate structure mainly uses the ventilation rate to reduce the influence of strong crosswinds on the running high-speed train, which can effectively ensure the safety of the train operation.

Embodiment 2

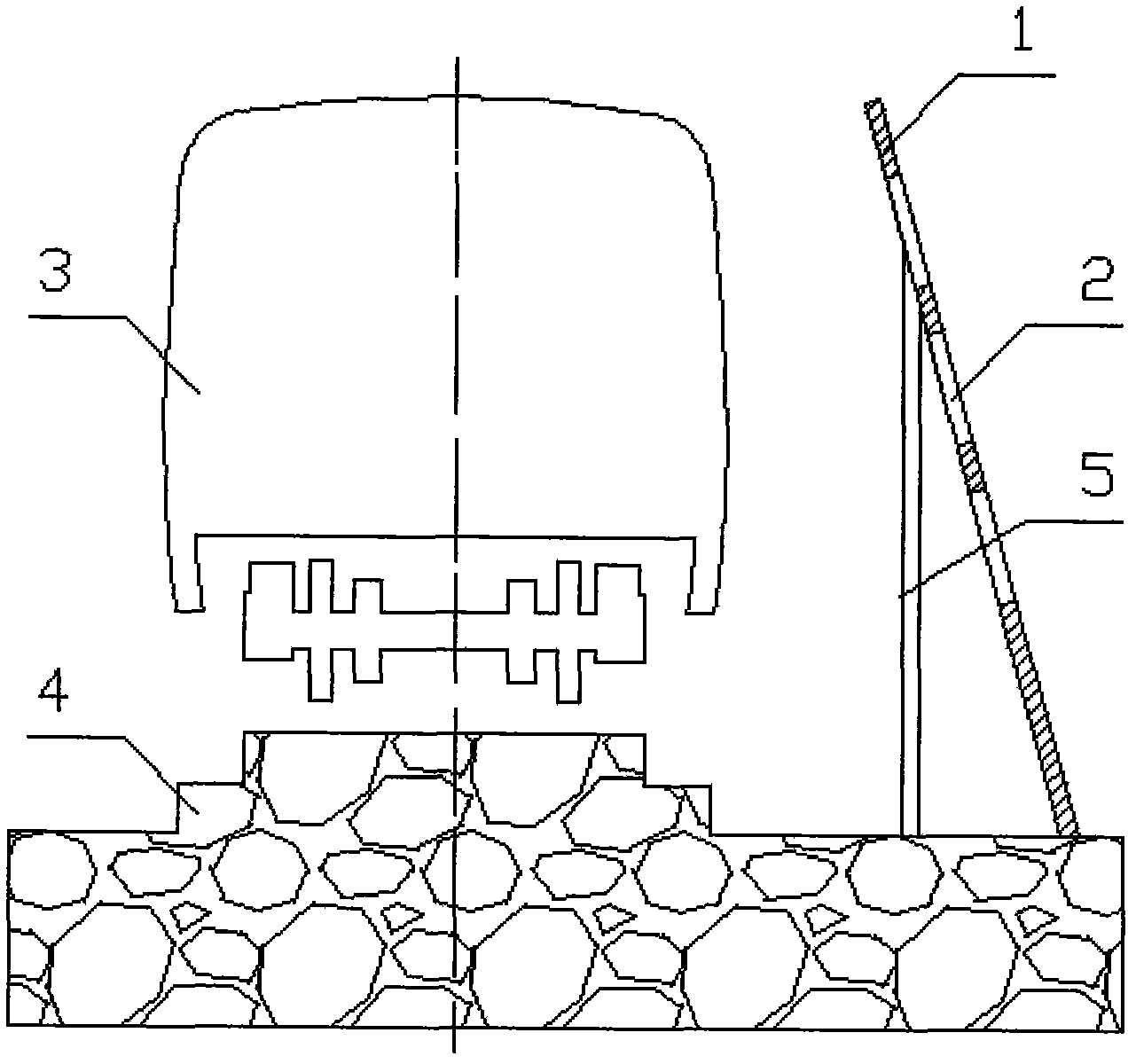

[0023] Embodiment 2: Angle-type structure.

[0024] It is basically the same as Embodiment 1, except that the windshield wall 1 is inclined about 15 degrees to the direction of the high-speed train body 3, and a reinforcing rod 5 is provided.

[0025] In addition to the effect of Embodiment 1, the windshield 1 of the inclined structure can also effectively change the wind direction of the strong crosswind, and can effectively reduce the component force of the strong crosswind vertically acting on the windshield, which can reduce the windshield of the windshield. self-respect.

Embodiment 3

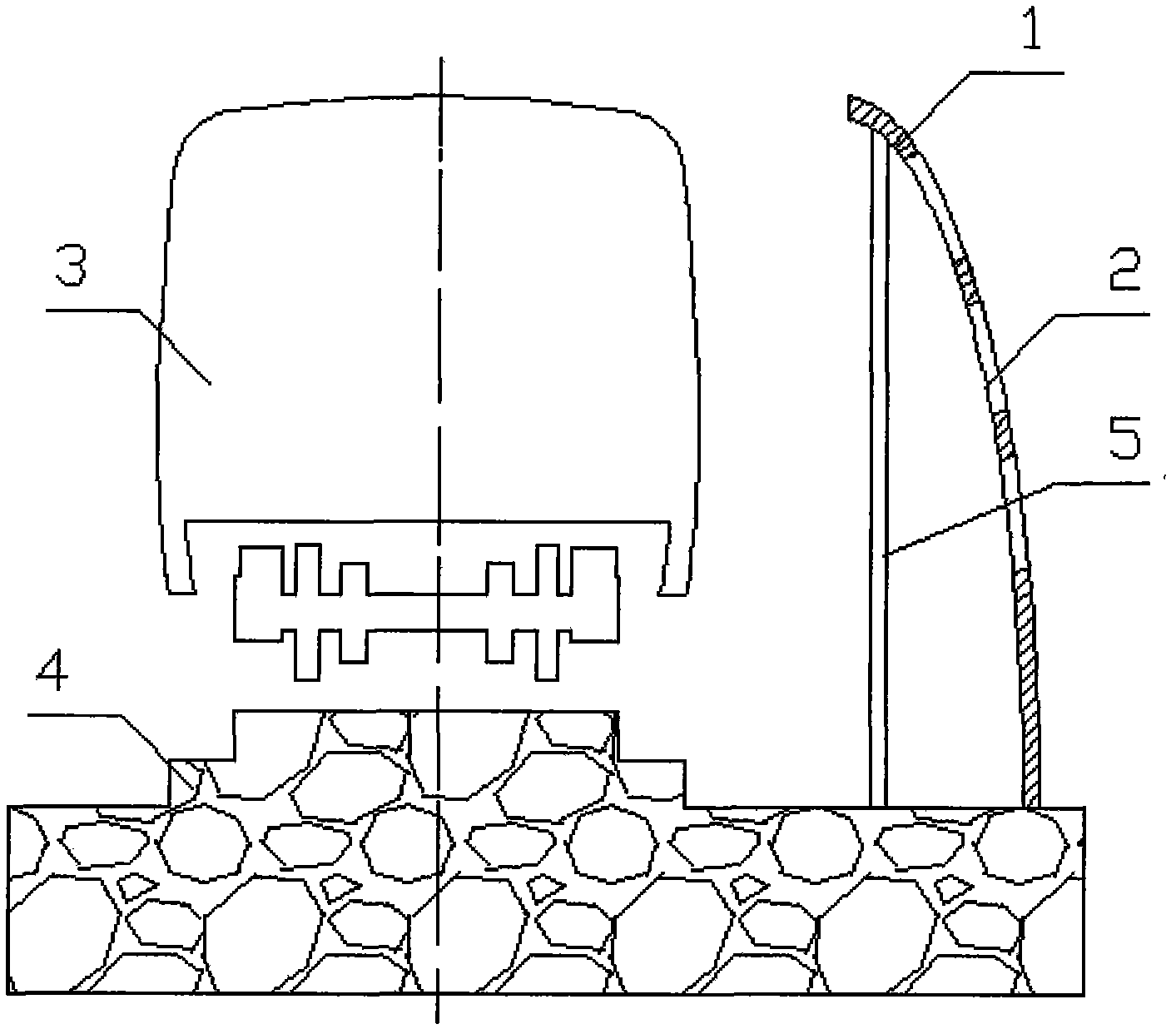

[0026] Embodiment 3: streamlined structure

[0027] It is basically the same as Embodiment 1, except that: the windward surface of the windshield wall 1 is a streamlined structure, and reinforcing rods 5 are provided.

[0028] In addition to the effects of Embodiment 1, the streamlined windshield can also effectively change the wind direction of the strong crosswind, and can effectively reduce the component force of the strong crosswind vertically acting on the windshield, which can reduce the self-weight of the windshield .

[0029] For example: the height of the embankment is 10 meters, the cross wind speed is 30 meters per second, and the train speed is 350 kilometers per hour. The test results show that:

[0030] 1) The leading vehicle receives the largest lateral force and overturning moment;

[0031] 2) The lateral aerodynamic force on the EMU running under the round-hole windshield is smaller than that under the square-hole windshield; the overturning moments of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com