Road sweeper

A road cleaning and vehicle body technology, applied in the field of sweeping vehicles, can solve the problems of high energy consumption, high manufacturing and use costs, and high noise, and achieve the effect of improving cleaning efficiency, improving cleaning effect, and simple working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

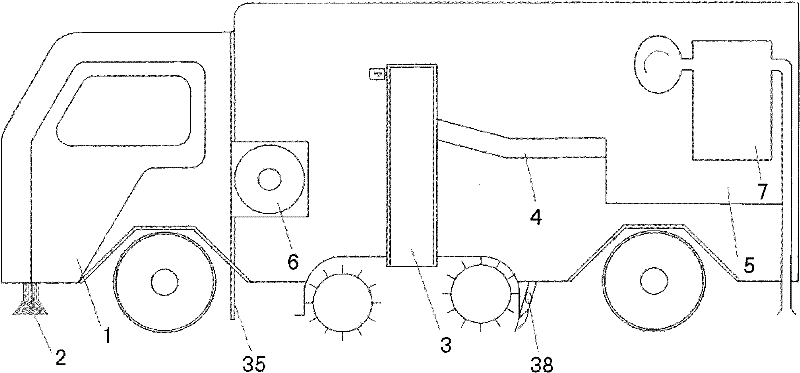

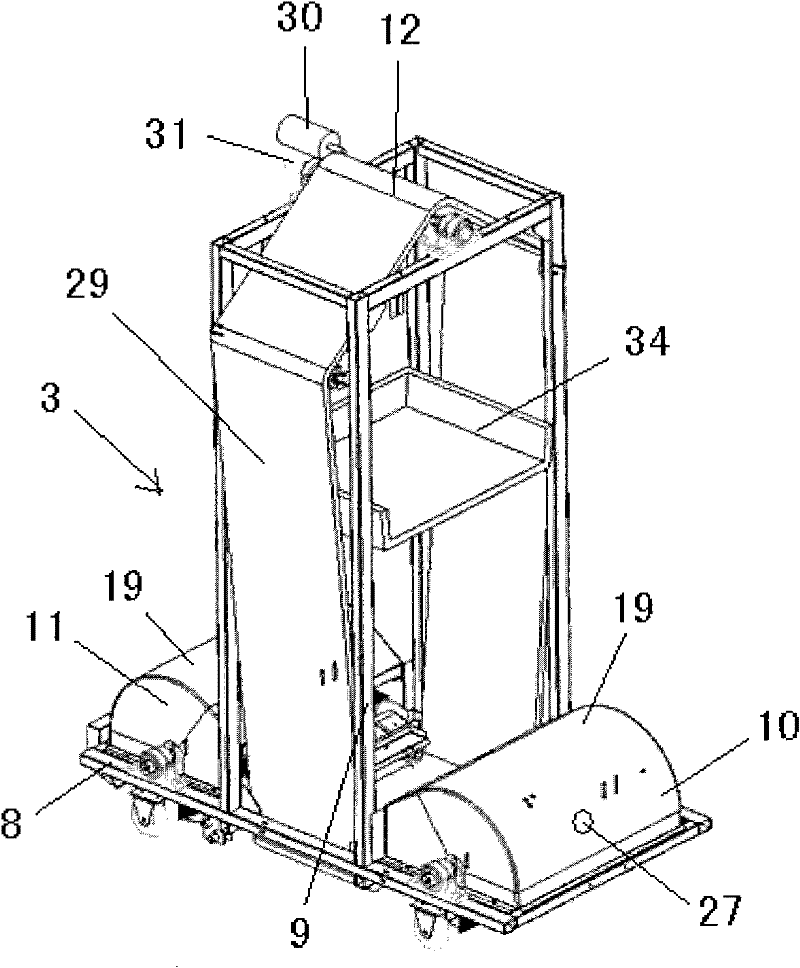

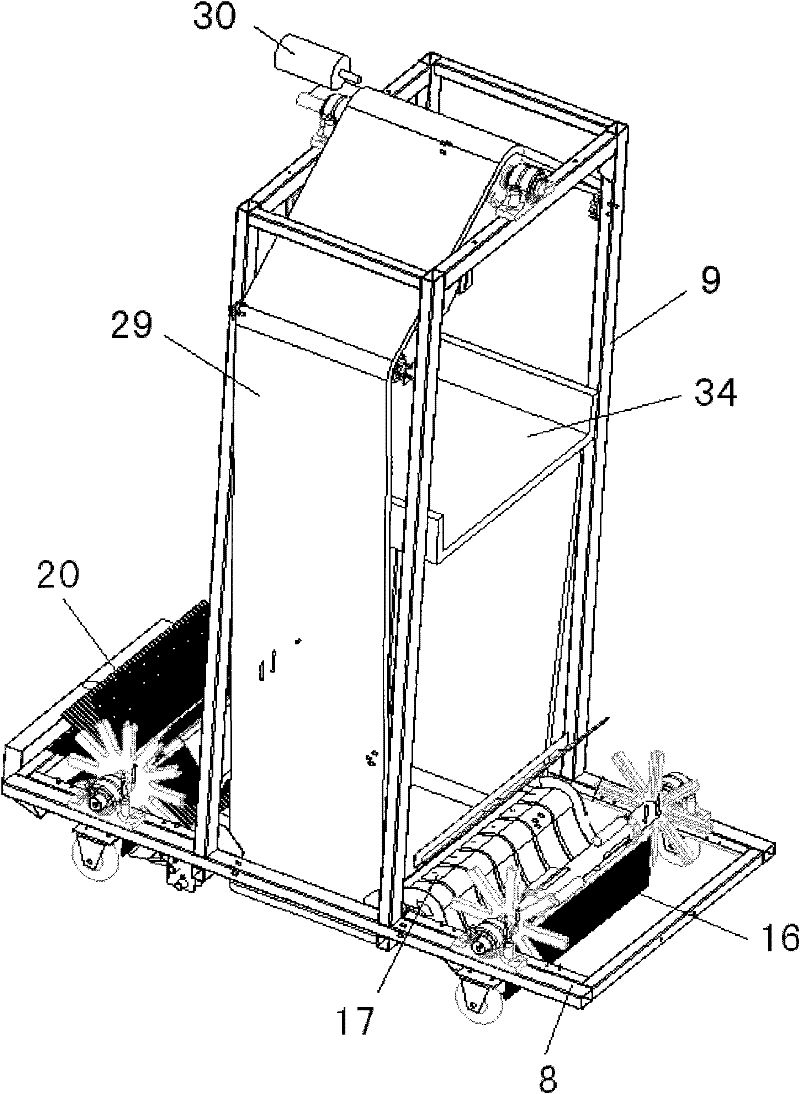

[0025] like figure 1 As shown, the present invention adopts mechanical simulation manual method to collect sundries and dust, and it comprises a car body 1 capable of walking. The two sides of the front part of the car body 1 are correspondingly provided with disc sweeping brushes 2 that expand the cleaning width. The internal control device controls its work. Between the front wheel and the rear wheel of the car body 1, a material collection and lifting device 3 with traveling small wheels is towed, and the material collecting and lifting device 3 will input the collected materials into a material collection box 5 through the material guide groove 4, Wherein, the material collection and lifting device 3 is powered by a power source 6 , and the power source 6 is arranged at the rear and lower part of the driver's cab of the car body 1 . At the after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com