High-efficiency LED lamp bulb

A LED light bulb, high-efficiency technology, applied in the direction of electric lamp circuit layout, lighting device cooling/heating device, lighting and heating equipment, etc., can solve the problems of reducing the luminous efficiency of the whole lamp, reducing the transmittance of the bulb shell, affecting vision, etc. , achieve the effect of low cost of driving circuit, improvement of luminous efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

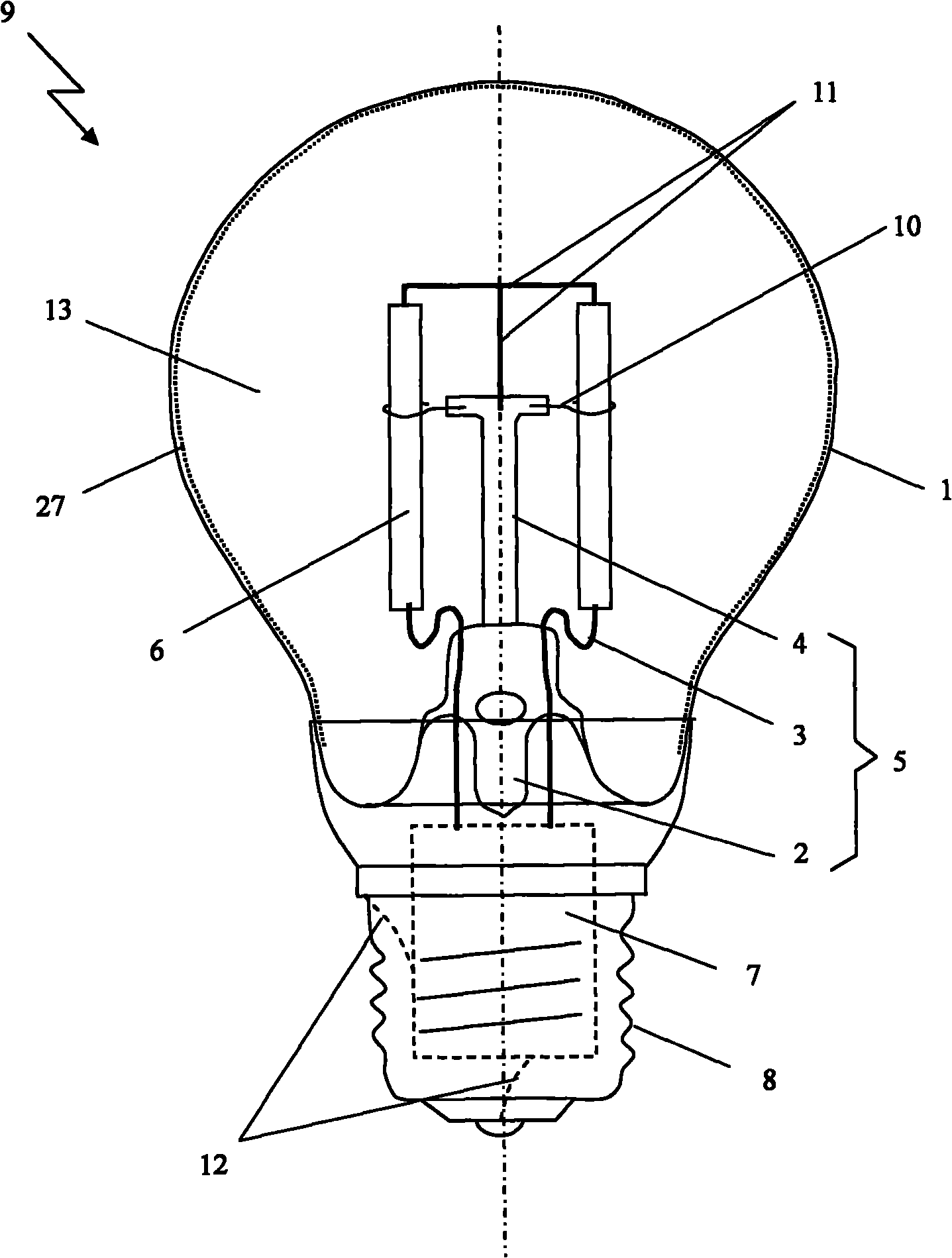

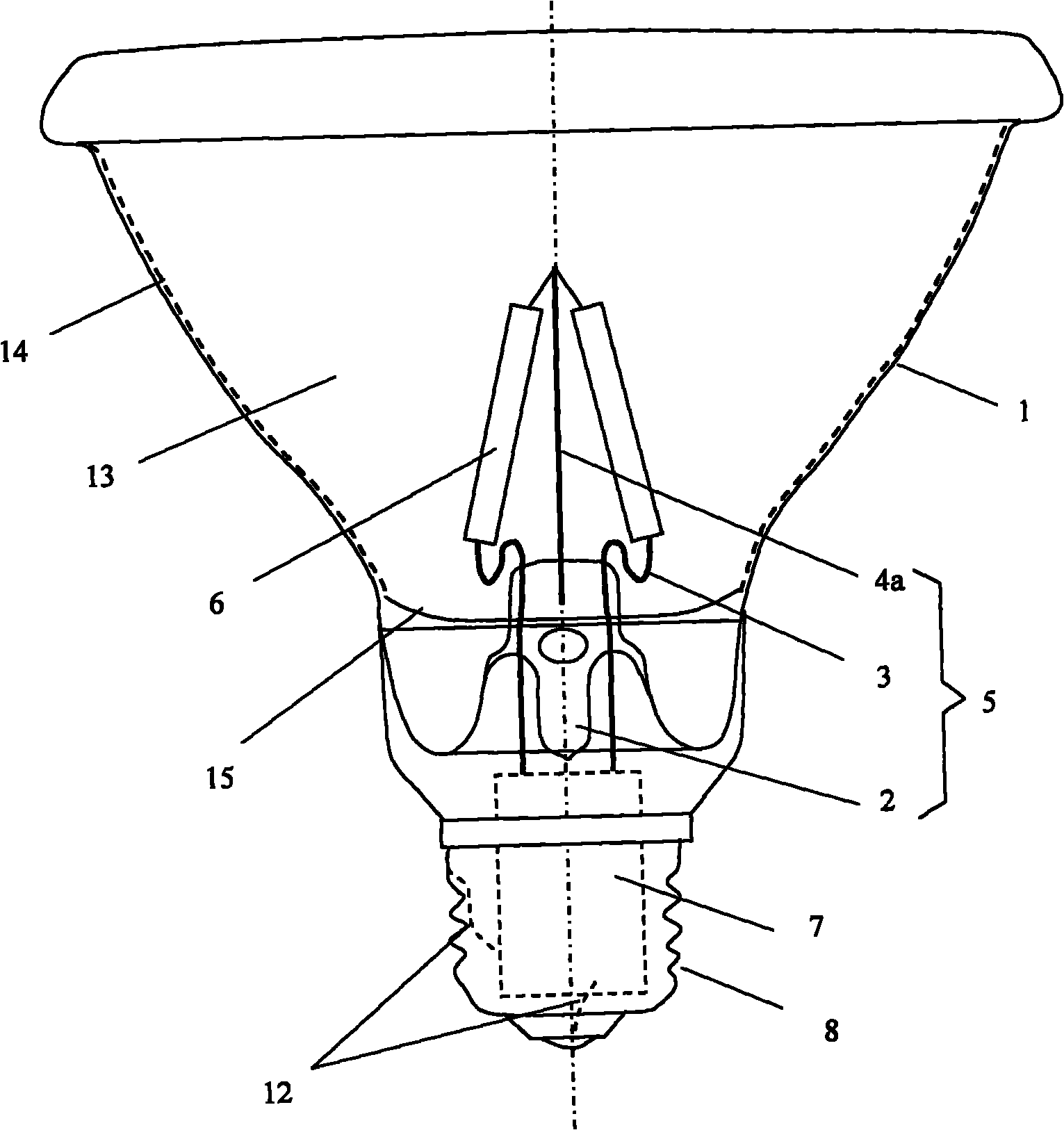

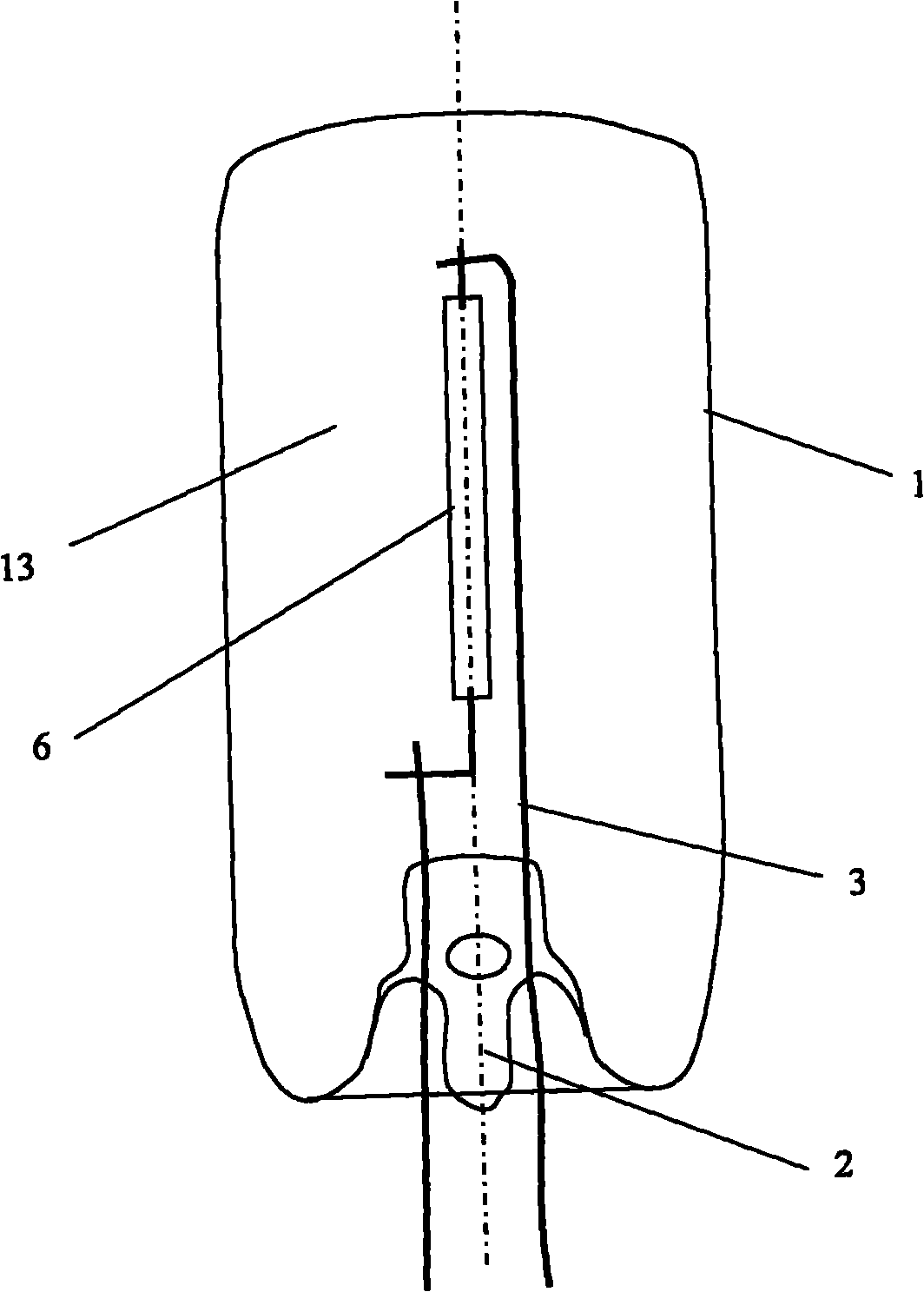

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of an embodiment of the high-efficiency LED light bulb of the present invention. The high-efficiency LED light bulb includes a light-transmitting bulb 1, a stem 5 with an exhaust pipe 2, an electrical lead wire 3 and a bracket 4, at least one LED light bar 6, a driver 7, and an electrical connector 8; The light-transmitting bulb 1 , stem 5 , LED light strip 6 , driver 7 and electrical connector 8 are connected to each other to form a whole lamp 9 . The LED lighting strip 6 is fixed on the stem 5 with metal wires 3, 10, 11, and its electrodes are connected to the electrical connector 8 through the electric lead wire 3 of the stem, the driver 7, and the connecting wire 12 to connect to an external power supply. , turn on the external power supply, the LED light strip 6 can be lighted; the light-transmitting bulb 1 and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com