Roundness measuring instrument of large precision bearing ring

A technology of roundness measuring instrument and bearing ring, which is applied in the direction of angle/taper measurement, mechanical counter/curvature measurement, etc. It can solve the problems of high price of large-scale measuring instruments and the inability to widely use precision large-scale bearings in measuring instruments, and achieve simple structure , Convenient processing, and the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

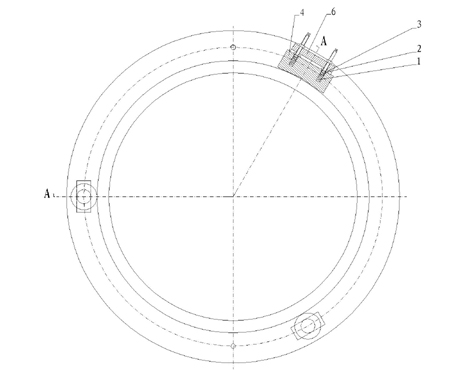

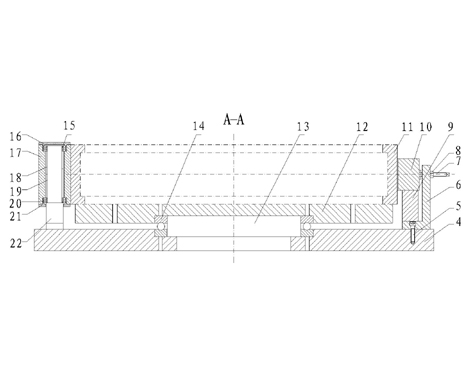

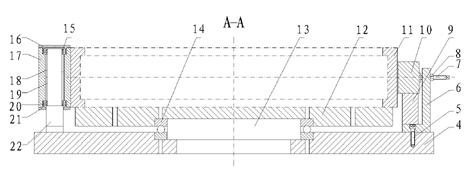

[0020] As shown in the figure, the precision large-scale bearing ring roundness measuring instrument of the embodiment of the present invention is composed of an upper base 12, a lower base 4, a clamping device, a main shaft support part and a supporting foot structure device, the clamping device and the supporting foot The structural device is fixed on the lower base 4 , and the main shaft supporting part is installed between the upper base 12 and the lower base 4 .

[0021] The clamping device of this embodiment includes a spring 1, a spring compression sleeve 2, a sealing nut 3, a screw 5, a support plate 6, an adjusting screw 7, a lock nut 8, a V-shaped block base 9, a V-shaped block 10, a lower base Seat 4 is provided with 10 threaded holes, two groups, used to fix support plate 6, spring 1, spring compression sleeve 2, sealing nut 3 and screw 5 to form a locking part, spring 1, spring compression sleeve 2. The sealing nut 3 is installed in the threaded hole, and the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com