Touch trigger measurement probe

A technology for measuring probes and stylus, which is applied in the field of measuring probes, can solve problems such as reducing measurement accuracy, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

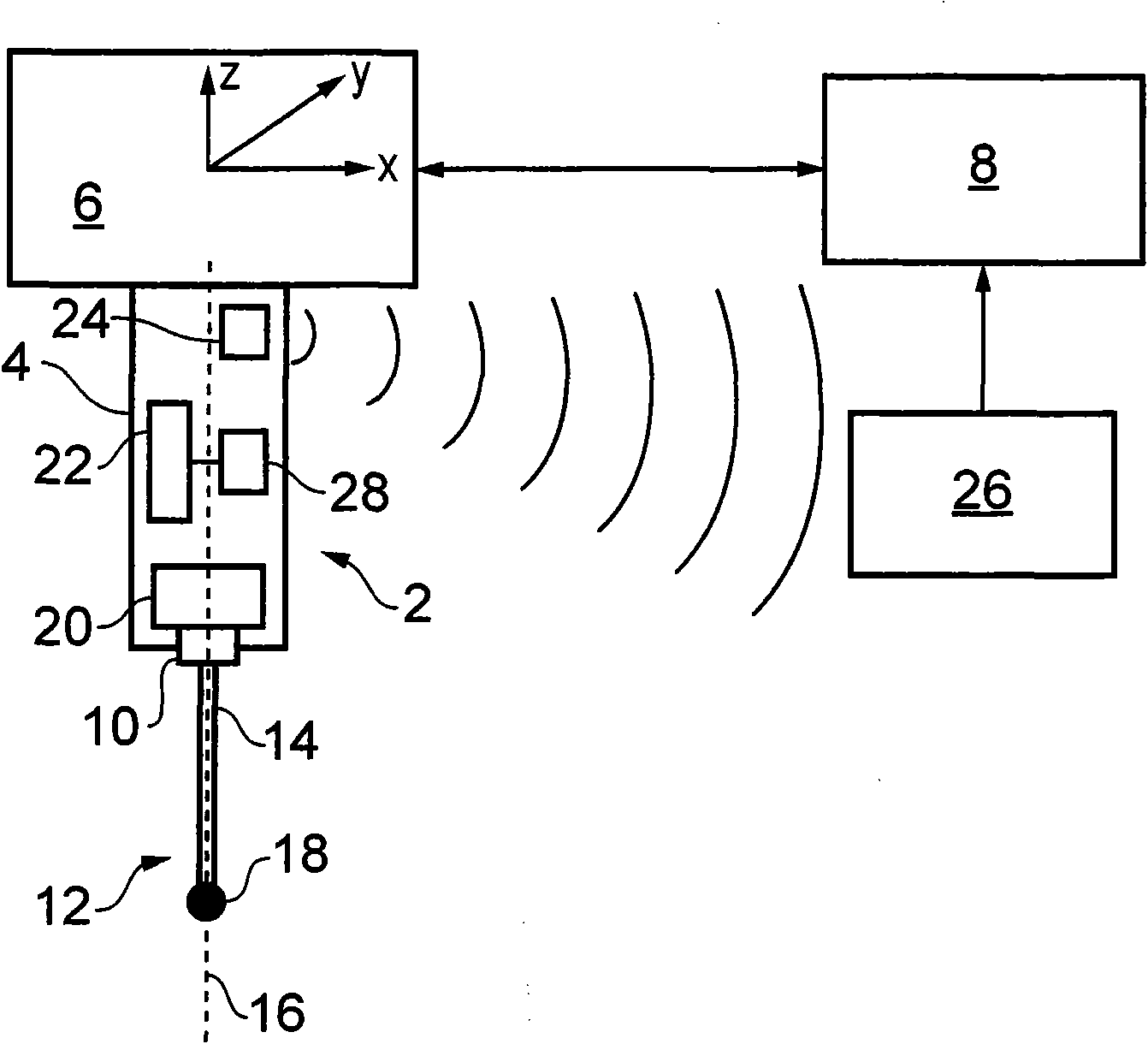

[0035] refer to figure 1 , shows a touch trigger measuring probe 2 having a probe housing or body 4 attached to a rotatable spindle 6 of a machine tool. The main shaft 6 is attached to a machine head (not shown) which is movable around the machine envelope along three mutually orthogonal axes (x, y, z). The movement of the spindle is controlled by a computer numerical controller 8 . The position of the spindle 6 is measured by a position encoder (not shown) and this position information is provided to the CNC 8 .

[0036] The measuring probe 2 has a stylus holder 10 to which a stylus 12 is attached by a screw connection. The stylus 12 includes a stem 14 for attachment to an object mounted to the machine bed, such as a workpiece or calibration artefact, extending along a longitudinal axis 16 and terminating in a stylus tip or ball 18 .

[0037] The stylus holder 10 is connected to the probe housing 4 via a strain sensor 20 . In this example, the strain sensor 20 comprises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com