Lithography apparatus using extreme uv radiation and having a volatile organic compounds absorbing member comprising a getter material

A technology of organic compounds and lithography equipment, applied in micro-lithography exposure equipment, optomechanical equipment, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Also in the following reference will be made to supports made of semiconducting material, but this is only a preferred embodiment for carrying out the invention, there will be cases where a device requires a support of a different type of material, for example an insulating or non-conductive material.

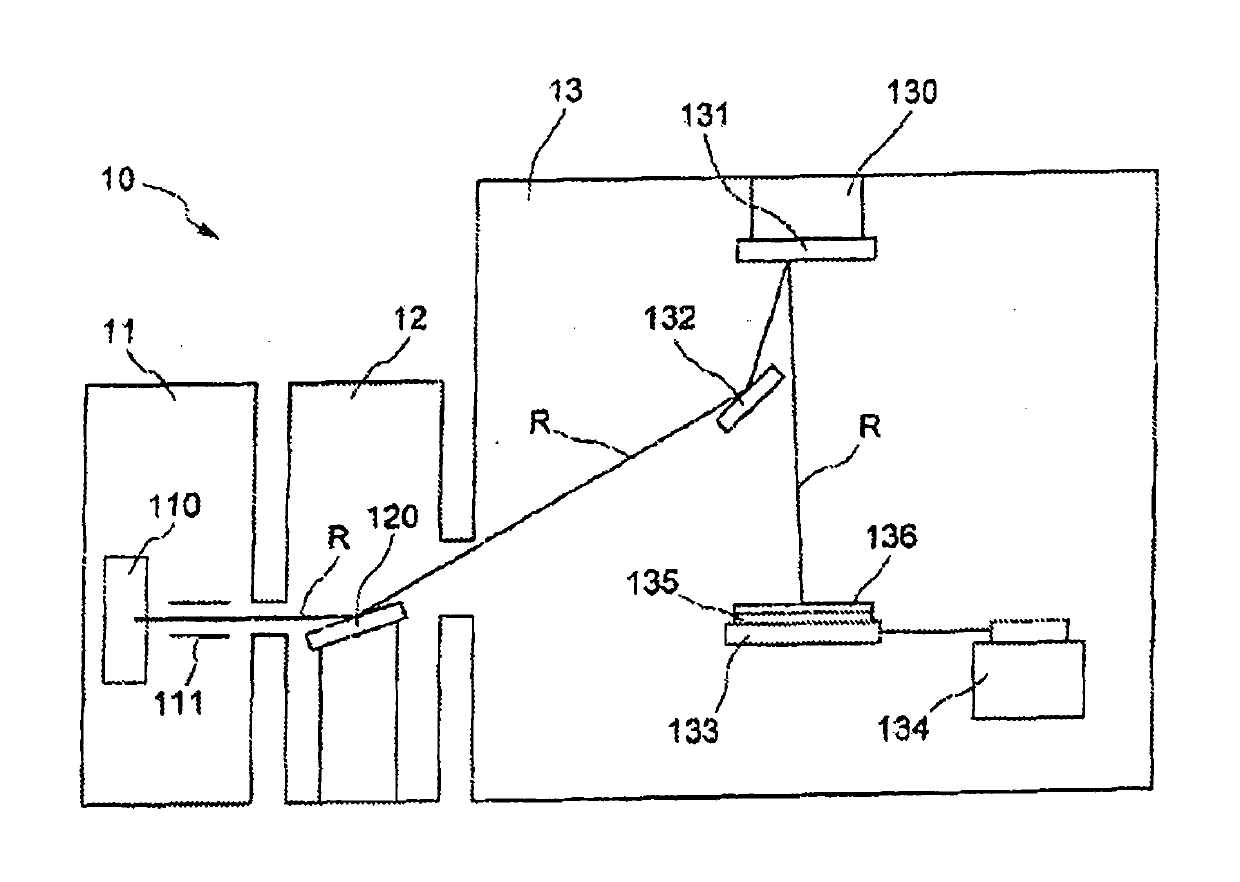

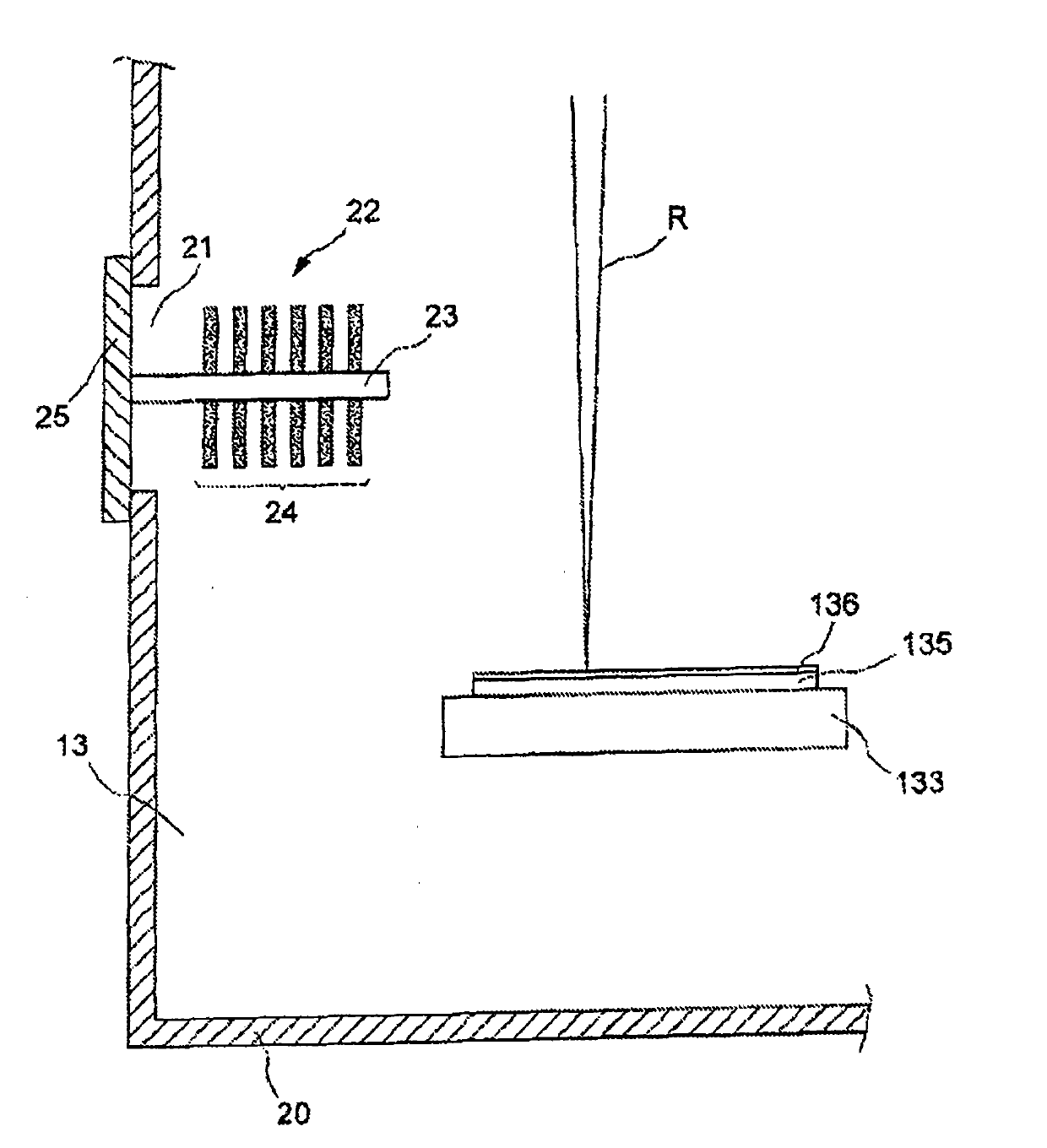

[0023] figure 1 EUVL devices are shown schematically and in a very simplified manner. The apparatus 10 comprises a first chamber 11 in which there is an EUV radiation source 110 and a collector 111 which collects a part of the radiation emitted from the source in all directions and directs the radiation to the next chamber; a second chamber 12 , comprising a monochromator 120 that selects a desired wavelength from the frequency band emitted from the source and directs monochromatic rays to the next cavity; and a processing cavity 13 that contains a holding mask 131 (the mask with design onto a polymeric film, which is arranged on a support made of semiconducting materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com