A catalytic cracking reaction regeneration method

一种催化裂化、反应再生的技术,应用在石油和化工领域,能够解决加大富气压机负荷、影响产品、增加能耗等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

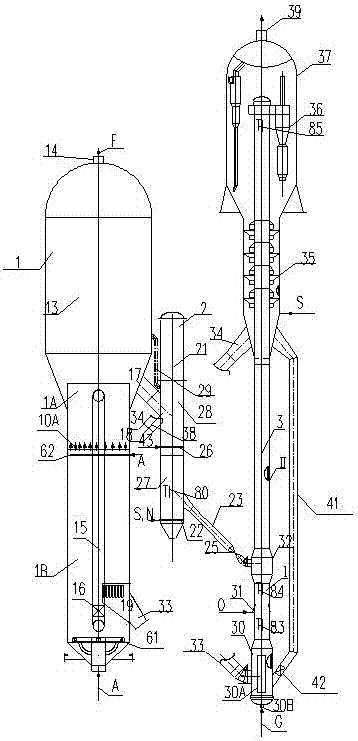

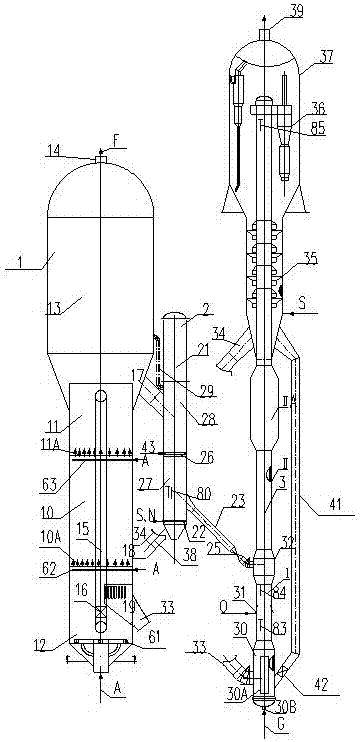

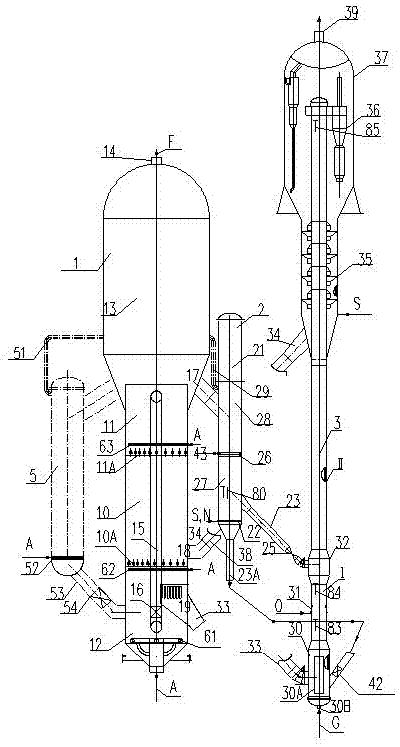

[0091] The device used in the reaction zone catalyst control and regeneration agent heat cooling method used in this embodiment can be found in image 3 shown.

[0092] An annual output of 150×10 4 t / a petroleum hydrocarbon catalytic cracking unit adopts coke tank regeneration, reaction regeneration is arranged side by side, riser reactor 3, catalyst purification cooler 2 produces medium pressure steam, catalyst purification cooler 2 adopts the type with its own vapor-liquid separator , the gas-liquid separator is directly connected to the catalyst purification cooler 2, and has the same diameter as the purification cooler. Reaction material and embodiment and the contrast ratio reaction condition of prior art are shown in the table below.

[0093]

[0094] See the following table for the size of the anti-regeneration device of the embodiment of the present invention and the comparative example of crude oil technology.

[0095]

[0096] The distribution of reaction pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com