MBS bridge type rectifier welding process

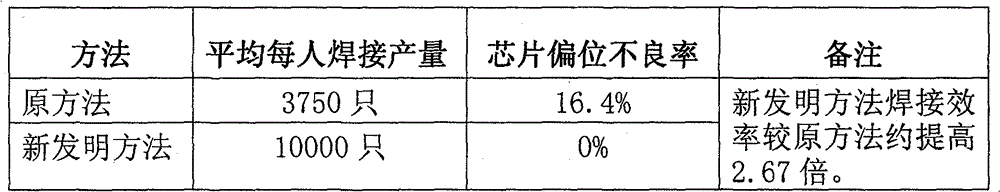

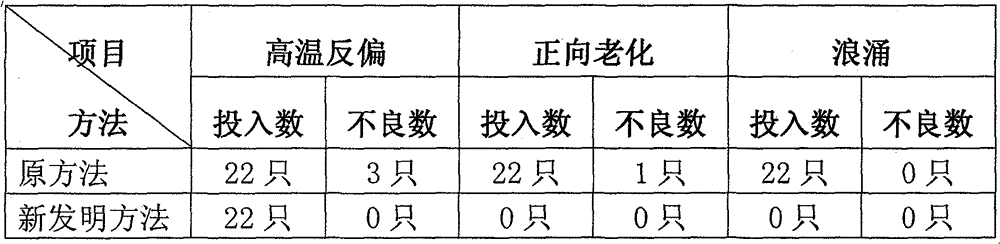

A welding process and bridge rectification technology, used in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of pre-soldered chips not easy to split, low efficiency, high cost, etc., and improve the welding deviation. The effect of reducing chip time and investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention easier to understand, the present invention will be described in more detail below in conjunction with specific embodiments.

[0017] First of all, design the chip directional suction cup, blank positioning cover, solder paste box and solder paste pen tooling. The specific design is as follows:

[0018] .Chip directional sucker design: design the hole depth of the current sucker from 0.5mm to 0.35mm, and increase the chamfer of 0.1mm around, so as to facilitate the 100% reverse (flip) function of the chip;

[0019] Blank positioning cover design: designed as a thin aluminum alloy frame, the purpose is to position the blank on the blank tray, so that the blank will not be lifted up during the solder paste dipping operation, resulting in uneven solder paste;

[0020] Solder paste box design: It is designed as a small aluminum alloy groove, and the solder paste dip pen is just placed in the groove; the purpose is to make each point of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com