Electrostatic sand-dispensing machine for multiple grinding materials and manufacturing process thereof

A technology of electrostatic sand planting and abrasives, which is used in the manufacture of tools, grinding devices, metal processing equipment, etc., can solve the problems of large random changes in the density of abrasives, and cannot guarantee the best use state, and achieves improved grinding efficiency. The effect of uniform abrasive density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

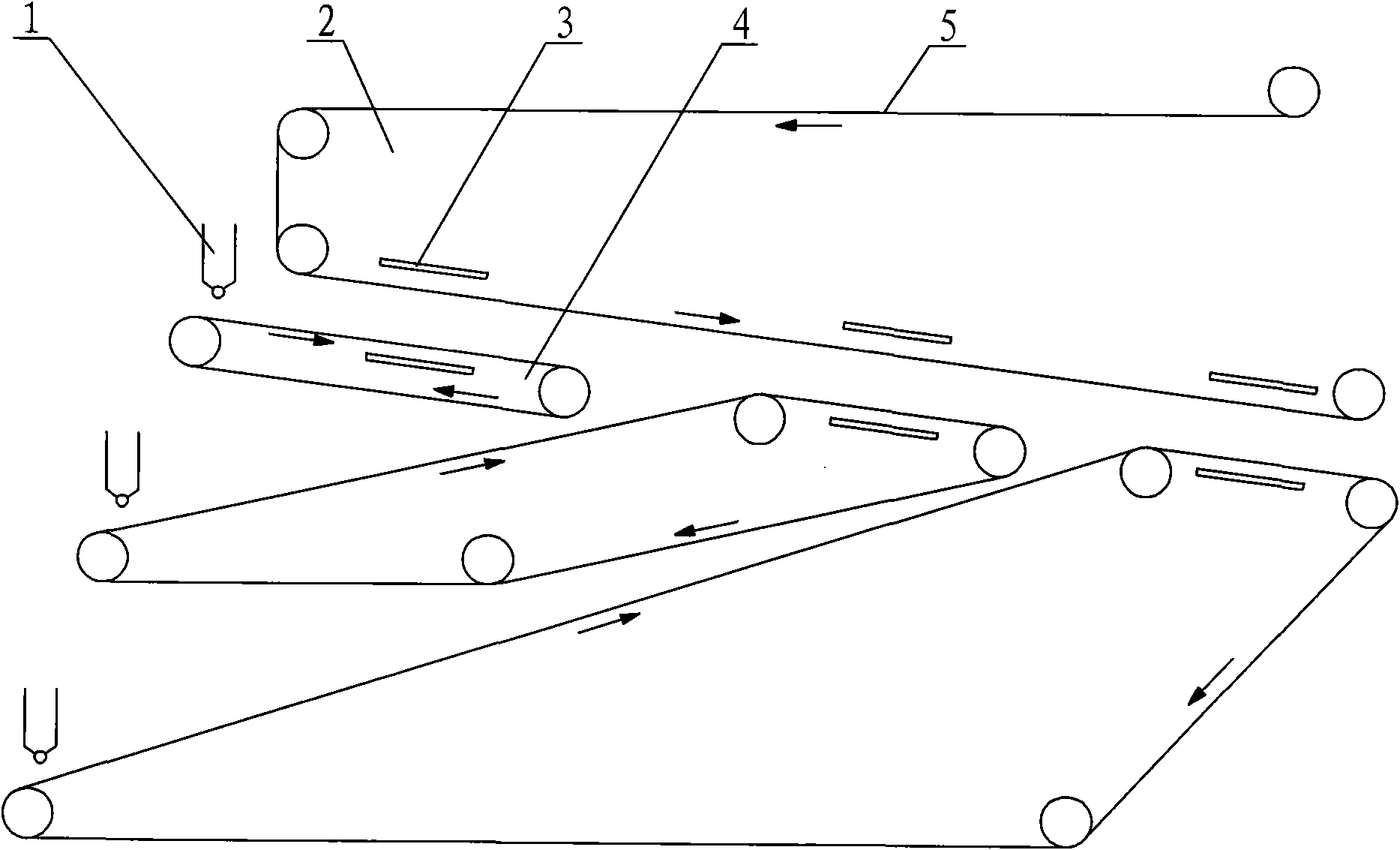

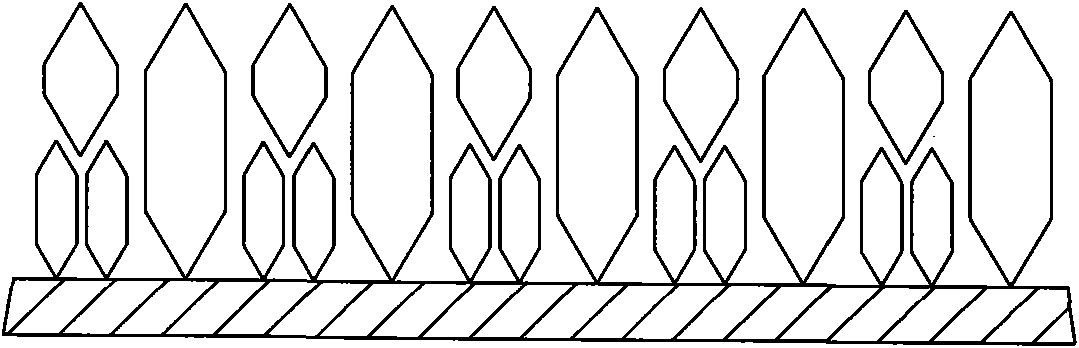

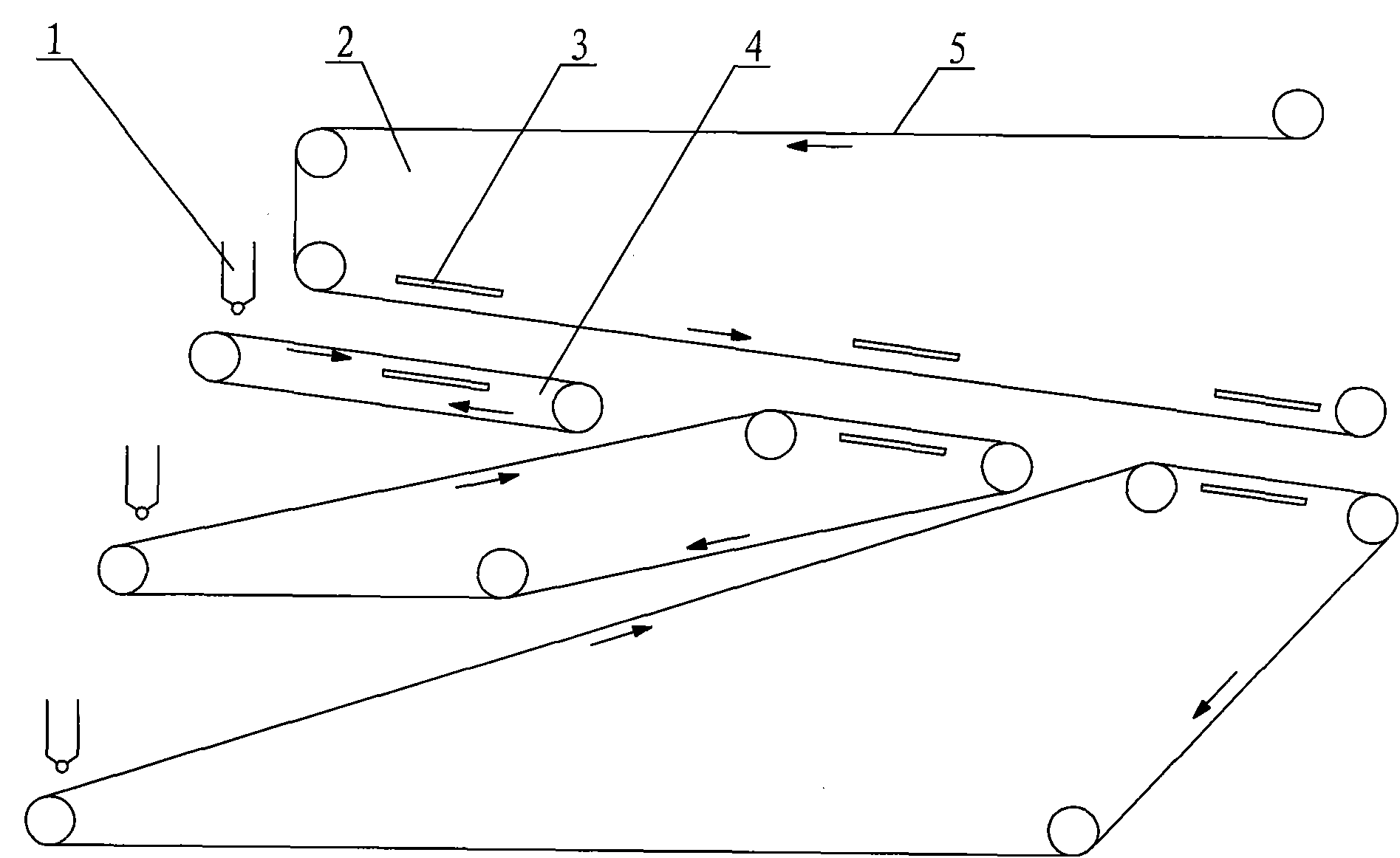

[0015] see Figure 1-Figure 2 , the electrostatic sand planting machine of various abrasive materials, including abrasive conveying device 4, cloth rolling device 2, and electrode plate group 3 arranged in both, and its abrasive conveying device 4 is provided with three groups, and all are arranged on the cloth rolling device 2 below.

[0016] The abrasive conveying device 4 is a rotary conveyor belt, and its sand planting area is parallel to the sand planting area of the cloth rolling device. Among them, the first group of rotary conveyor belts is a two-stage conveyor belt, and the second and third groups of rotary conveyor belts are four-stage conveyor belts. Each set of rotary conveyor belts is provided with a sand falling bucket 1 above the feeding end, and an abrasive recovery device (not shown in the figure) is provided below the end of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com