Miniature sprayer pump core and two-stroke pressing method thereof

A sprayer and pump core technology, which is applied in the direction of injection device, liquid distribution, closing, etc., can solve the problems of complex sealing structure, inconvenient assembly, automatic production, poor spraying effect, etc., and achieve wide application range, good atomization effect, increase The effect of pressing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

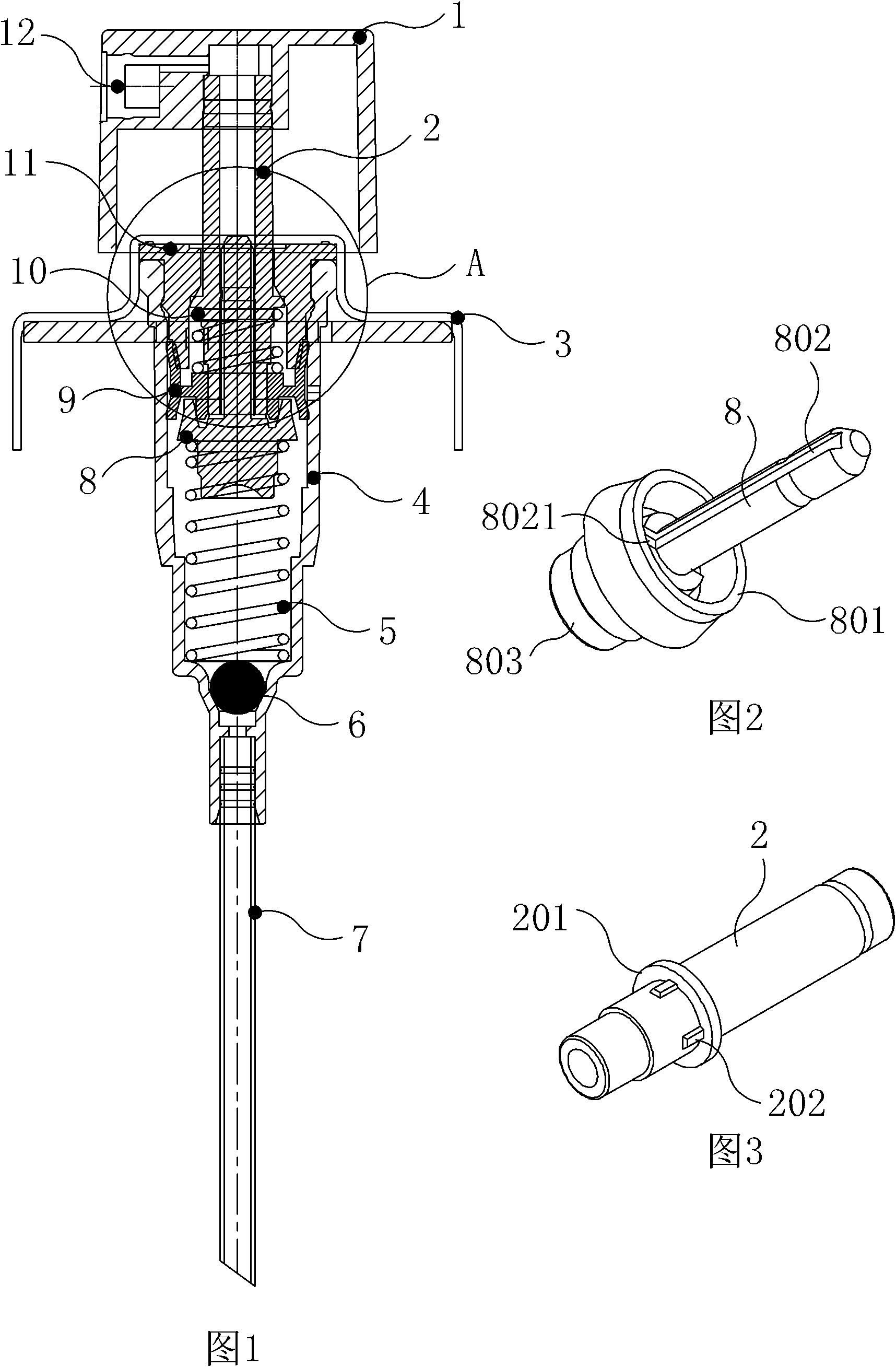

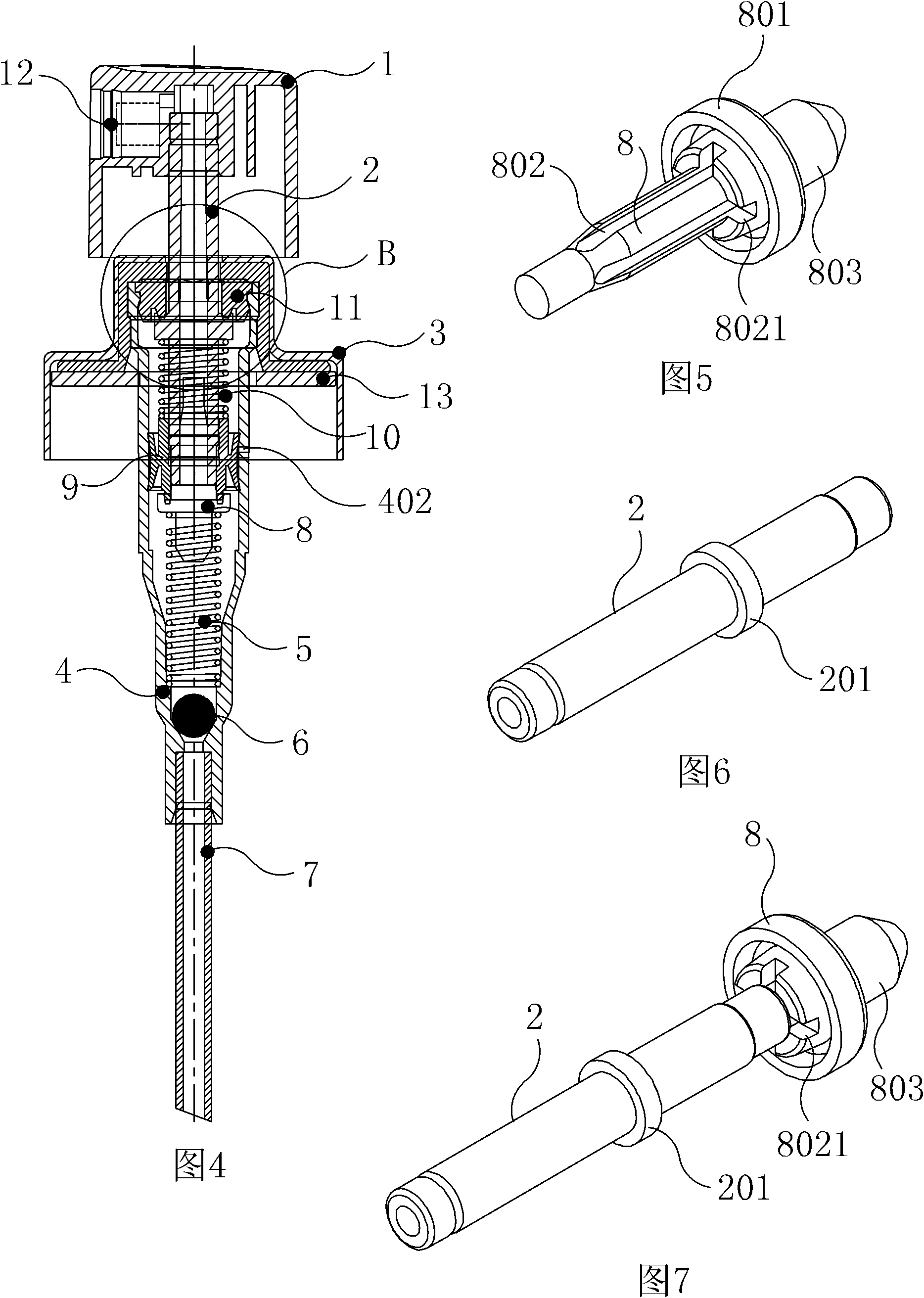

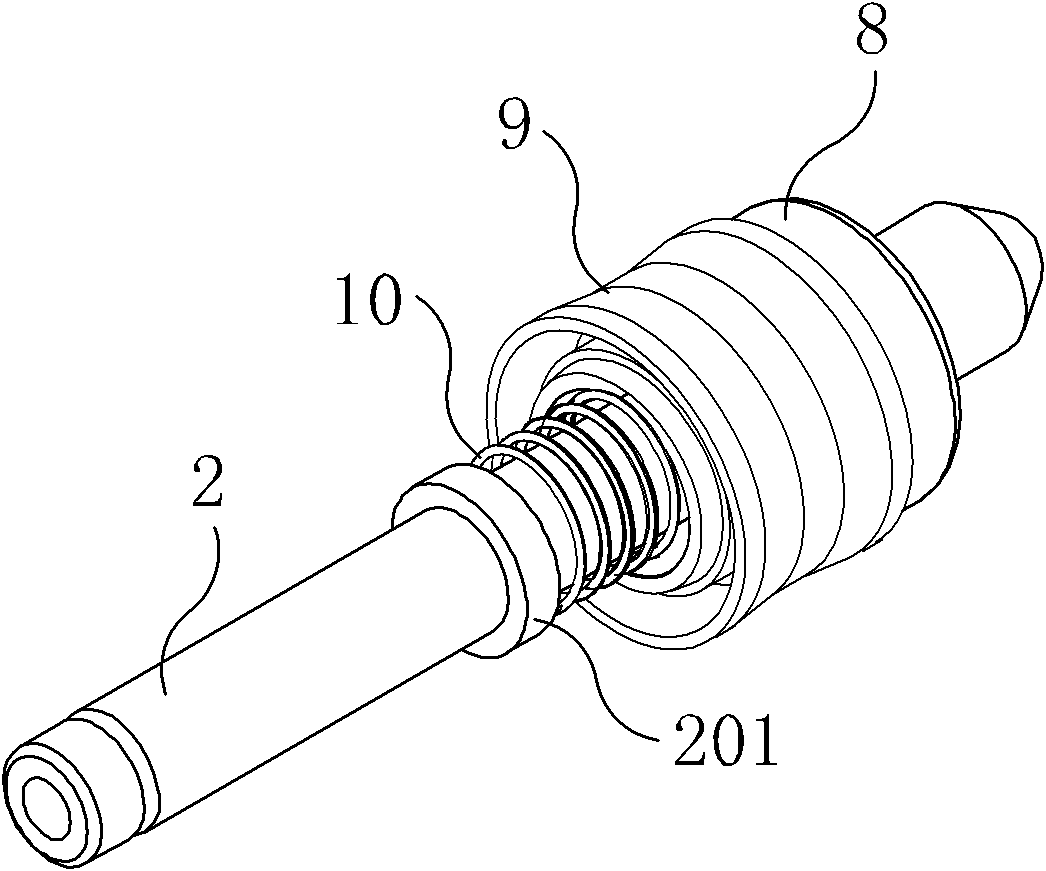

[0032] The structure, use and principle of the present invention will be further described in conjunction with Embodiments 1 and 2 of the accompanying drawings. As shown in the figure, the pump cores of Embodiments 1 and 2 include a piston rod 2, a pump body 4, a large spring 5, a glass ball 6, a lower valve 8, a piston 9, a small spring 10, a connecting cover 11, and the pump body in the pump core The water inlet of the water inlet is provided with a glass ball, and the glass ball is offset against one end of the large spring, and the other end of the large spring is inserted into the spring post 803 of the lower valve, and is offset against the rib 801 of the lower valve, and the piston and the small spring are inserted into the lower valve in turn. valve, and the lower valve is inserted into the piston rod with an interference fit. At this time, the diversion groove 802 of the outer diameter of the lower valve is placed on the inner diameter of the piston rod, and the diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com