Four-way valve for air conditioner

A four-way valve and air-conditioning technology, which is applied in the field of four-way valves, can solve problems such as high production requirements, high production costs, and leakage, and achieve the effects of great flexibility and adaptability, simple and reasonable structure, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

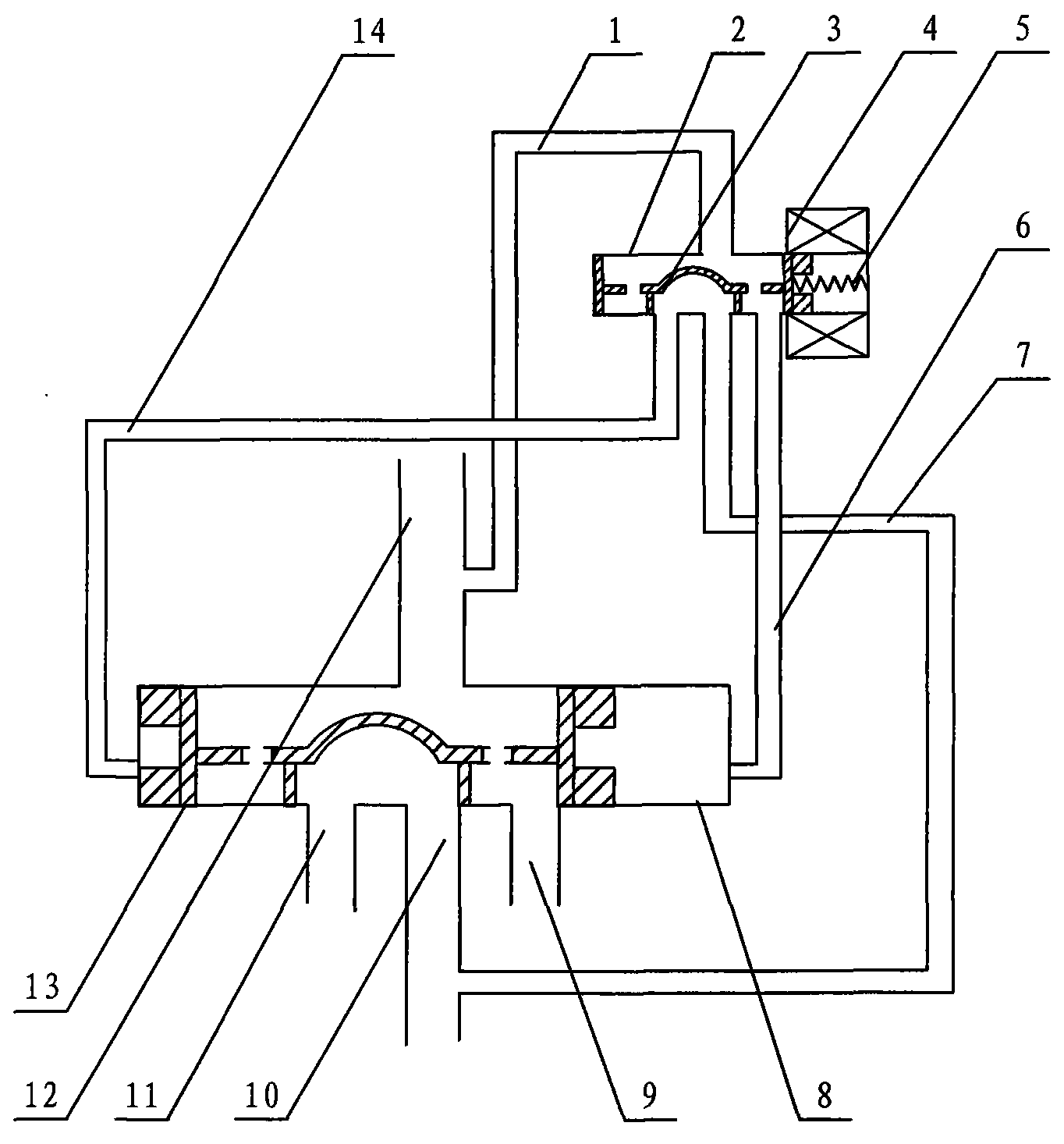

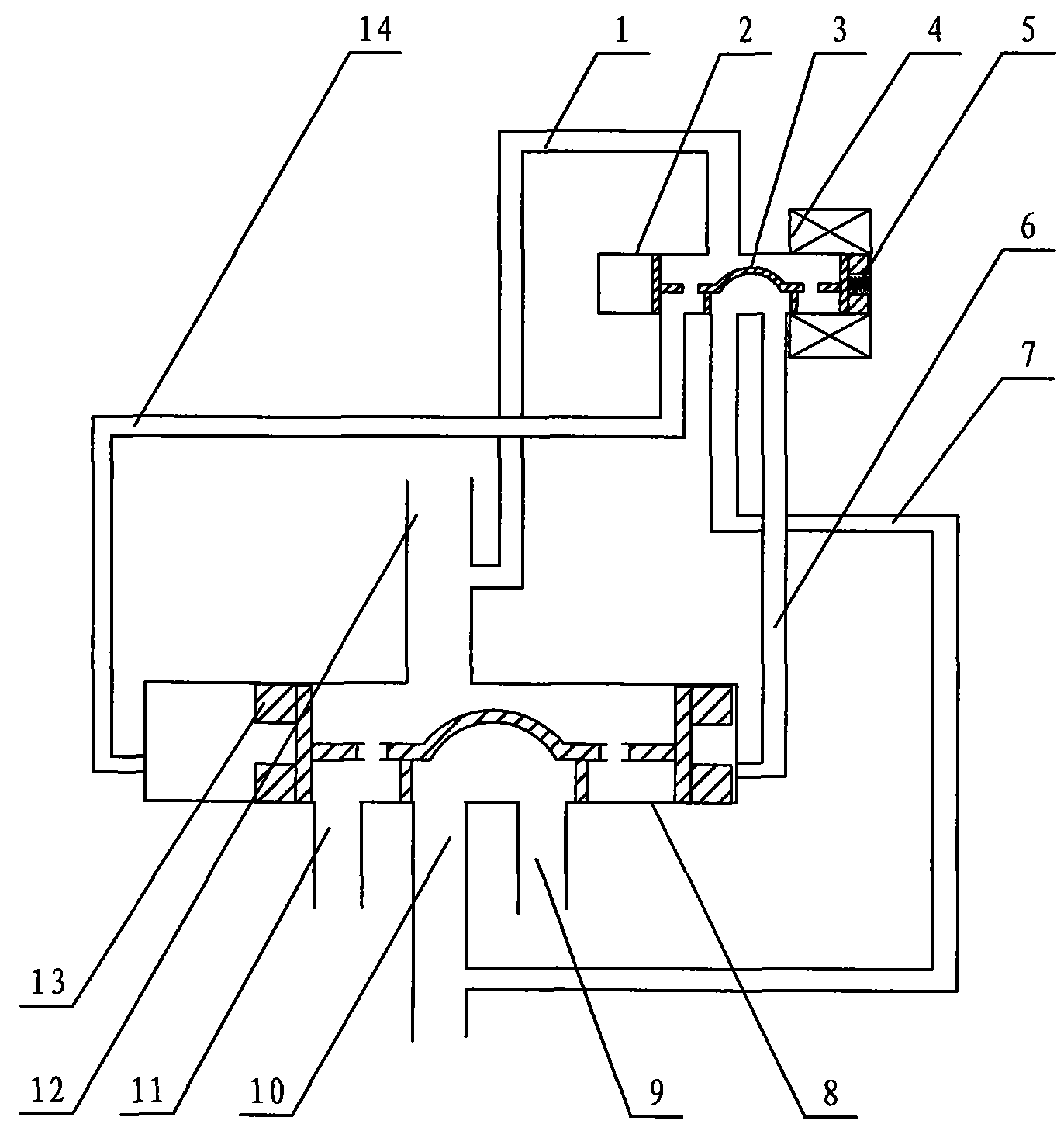

[0025] see Figure 3-Figure 4 , the four-way valve for the air conditioner includes a four-way valve block 3 arranged in the four-way valve housing 5, and the four-way valve housing 5 is provided with a four-way valve exhaust communication pipe 4 and a four-way valve communicating with its inner cavity. The evaporator connecting pipe 9, the four-way valve return air connecting pipe 10 and the four-way valve condenser connecting pipe 11.

[0026] This embodiment is a specific structure in which springs and related electromagnetic coils are provided at both ends of the four-way valve block 3 , namely, the left end and the right end.

[0027] In this embodiment, the spring includes a left spring 2 and a right spring 7 , and the electromagnetic coil includes a left electromagnetic coil 1 and a right electromagnetic coil 6 . The left and right ends of the four-way valve block 3 are respectively connected with one end of the left spring 2 and the right spring 7, the other end of th...

no. 2 example

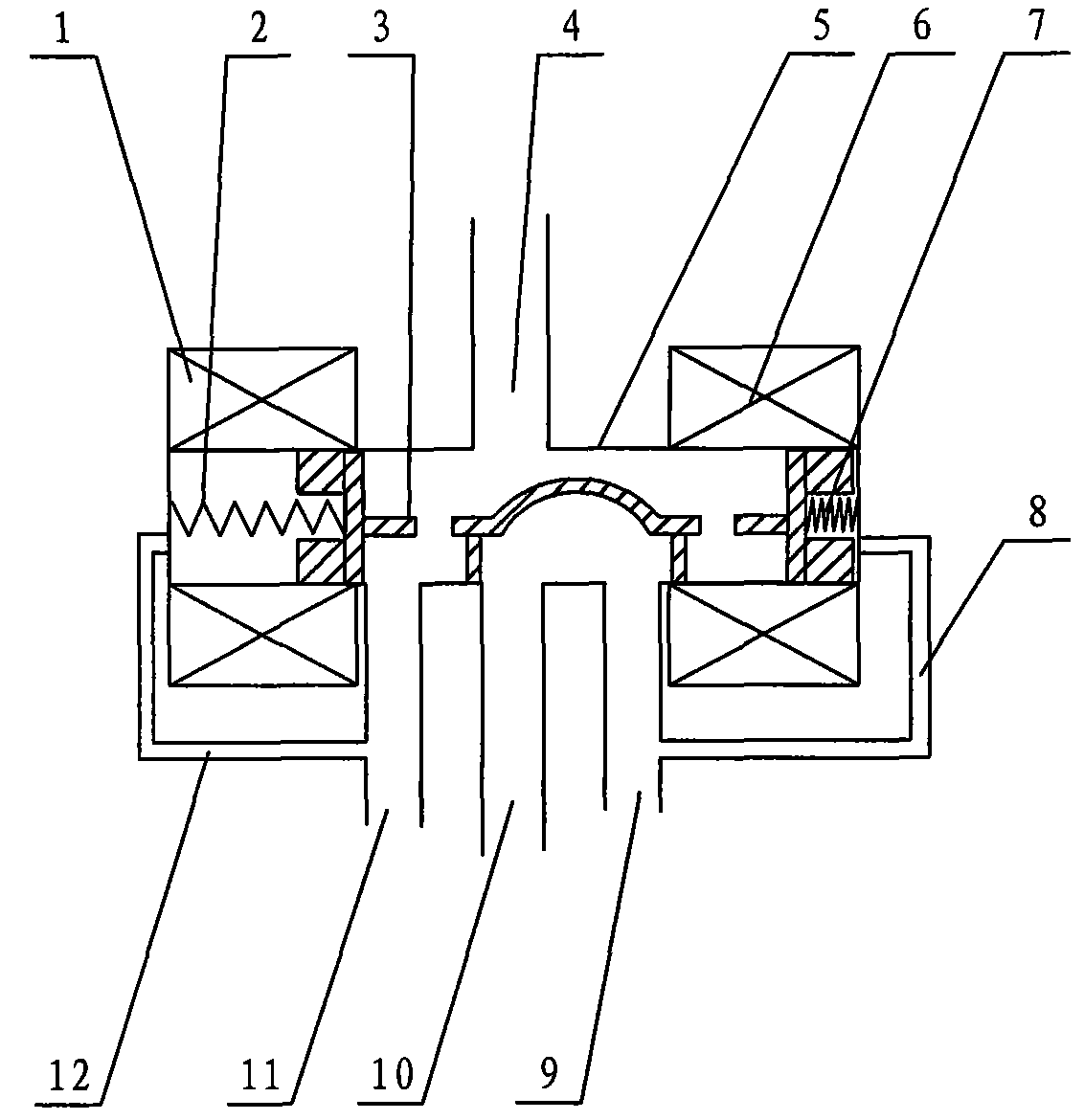

[0035] see Figure 5-Figure 6 , is only at one end of the four-way valve valve block 3, that is, the left end or the right end, a specific structure in which springs and related electromagnetic coils are provided. In this embodiment, only the right spring and the related right electromagnetic coil are provided at the right end of the four-way valve block 3 for specific description.

[0036] The right end of the four-way valve valve block 3 is connected with one end of the right spring 7, and the other end of the right spring 7 is connected with the right side inner wall of the four-way valve housing 5, and the right side of the four-way valve housing 5 is provided with a device for controlling the right spring. 7 telescopic right electromagnetic coil 6.

[0037] 1. In cooling mode, the right electromagnetic coil 6 is energized, and the right spring 7 is in a contracted state under the action of electromagnetic force, and the four-way valve block 3 is driven to overcome the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com