Novel high-power LED panel light

A technology of LED panel lights and LED lamp beads, which is applied in the direction of cooling/heating devices of lighting devices, lighting and heating equipment, point light sources, etc., and can solve the problem of no obvious advantages, complicated circuit structure, and insignificant long-life characteristics of LEDs. and other problems, to achieve the effect of convenient maintenance, uniform brightness, high light efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

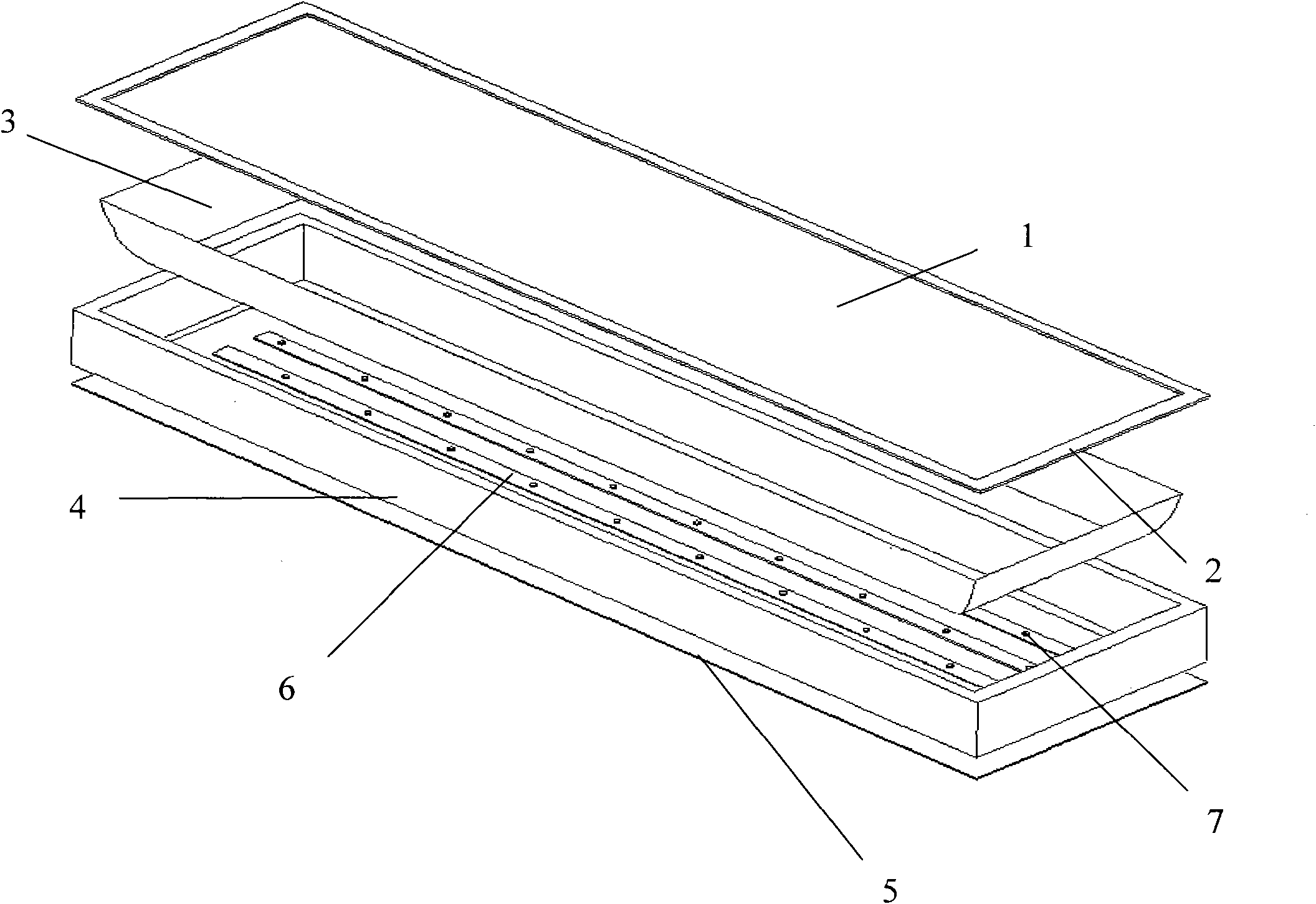

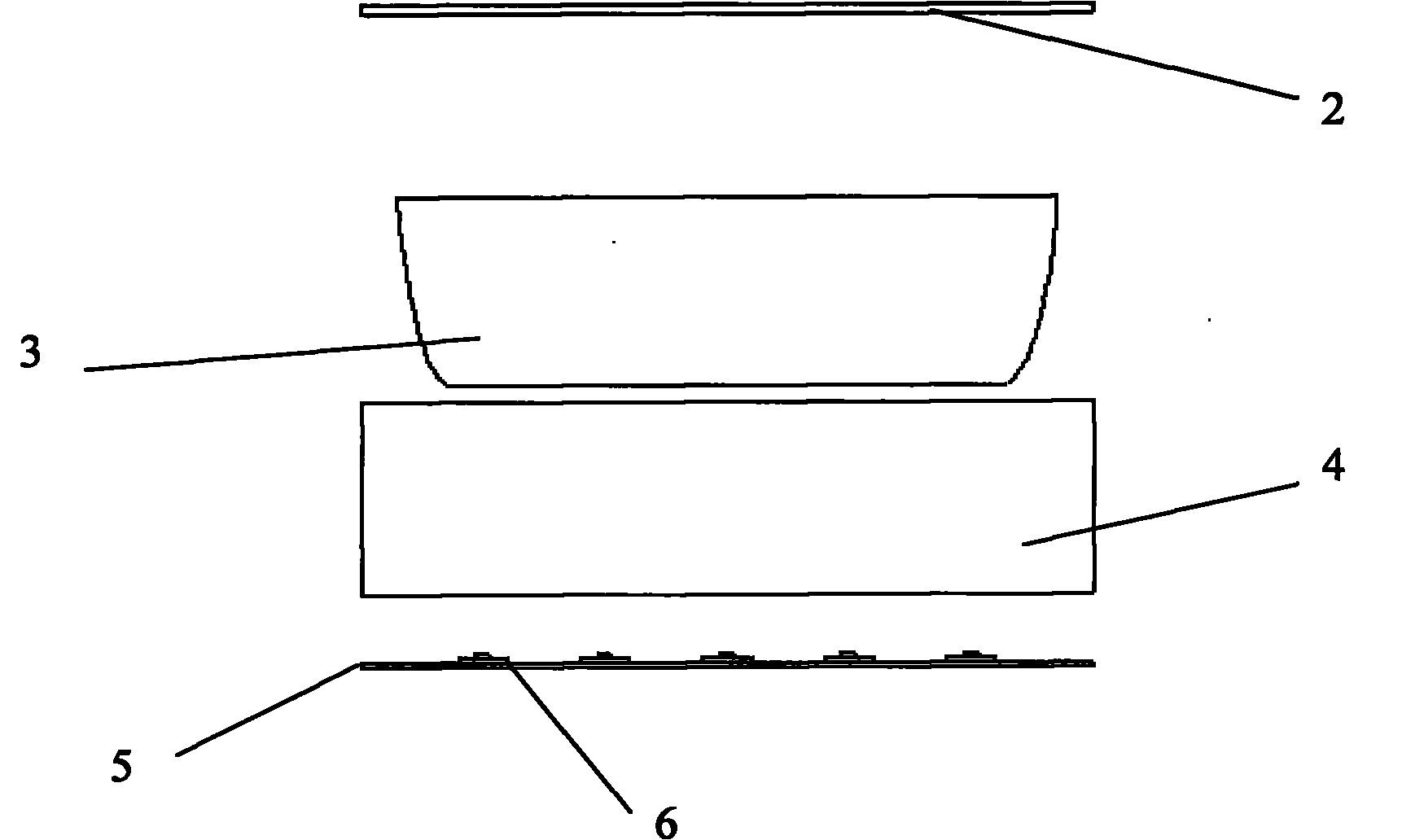

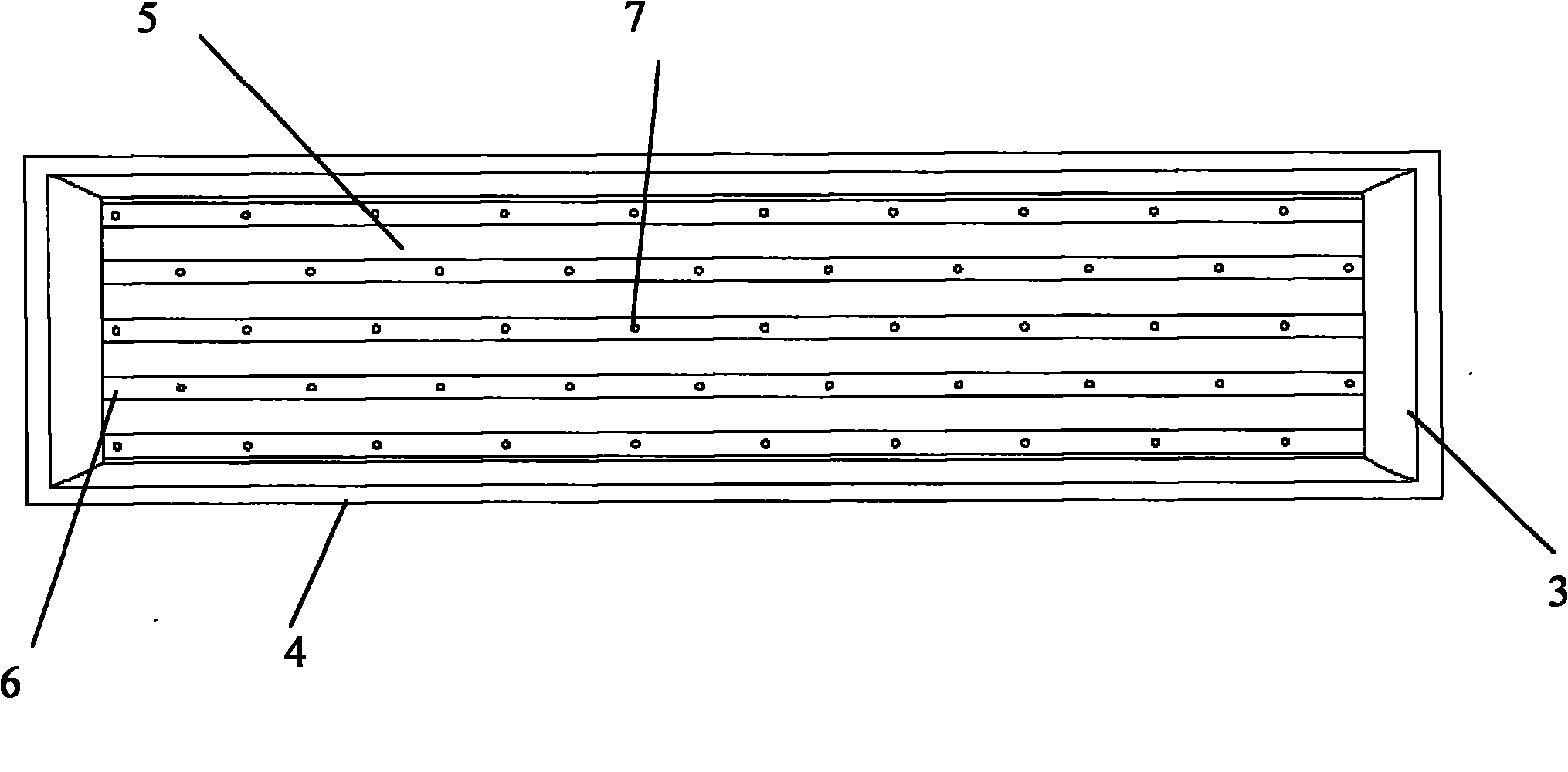

[0020] Such as Figure 1~3 As shown, a high-power LED panel light includes a bottom aluminum plate 5, a lamp front cover 2, a lamp side frame 4, and a long strip aluminum substrate 6. The bottom aluminum plate 5 and the lamp side frame 4 are connected to form a shell with an opening. The edge of the opening is connected with the edge of the lamp front cover 2 to form a space, and a plurality of strip-shaped aluminum substrates 6 are installed on the bottom aluminum plate 5, and the plurality of strip-shaped aluminum substrates 6 are arranged and installed equidistantly along the short side of the lamp; A plurality of high-power LED lamp beads 7 are arranged at equal intervals along the long side direction of the elongated aluminum substrate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com