Adhesive structured pigtail type detector

A technology of detectors and detector chips, applied in the field of detectors, can solve problems such as increasing processing costs and affecting the integrity and consistency of product surface shapes, so as to avoid glue bursting, ensure integrity and consistency, and reliability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

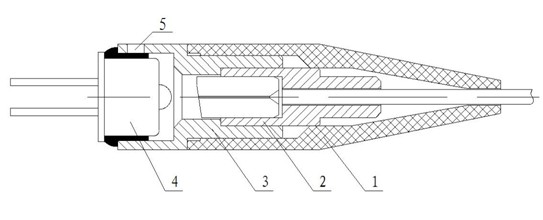

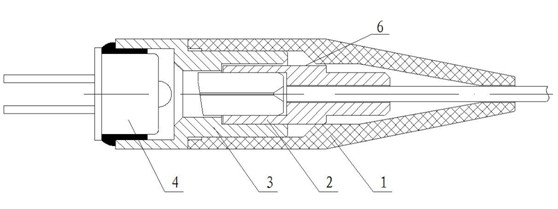

[0011] An adhesive structure pigtail type detector, such as figure 2 As shown, it includes a rubber sheath 1 , an optical fiber assembly 2 , a metal shell 3 , a detector chip 4 and a platform 6 .

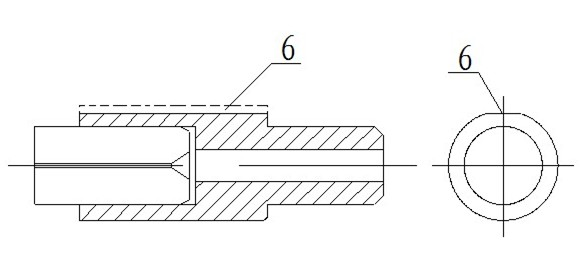

[0012] like image 3 As shown, when the optical fiber assembly 2 is processed, a platform 6 is processed on its outer circle with a depth of 0.01 to 0.5 mm, and the best effect is when the depth is 0.1 mm. The gap between the optical fiber assembly 2 and the metal shell 3 is too small, so that dust and impurities can easily enter the inside of the device, and the ventilation effect of the device is not bad because the gap between the optical fiber assembly 2 and the metal shell 3 is too small. The number of platforms is not limited to one, but can also be two or more. The number and depth of platforms can be matched, and the most appropriate number of platforms and depth of platforms can be selected on the basis of comprehensive consideration of processing costs and product perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com