Discrete procedure inserting and dispatching method in mixed line production

A scheduling method and process technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as few and difficult to adapt to the manufacturing environment, and meet the needs of the mixed operation mode of the workshop and the overall equipment utilization rate The effect of improving and improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme and accompanying drawings.

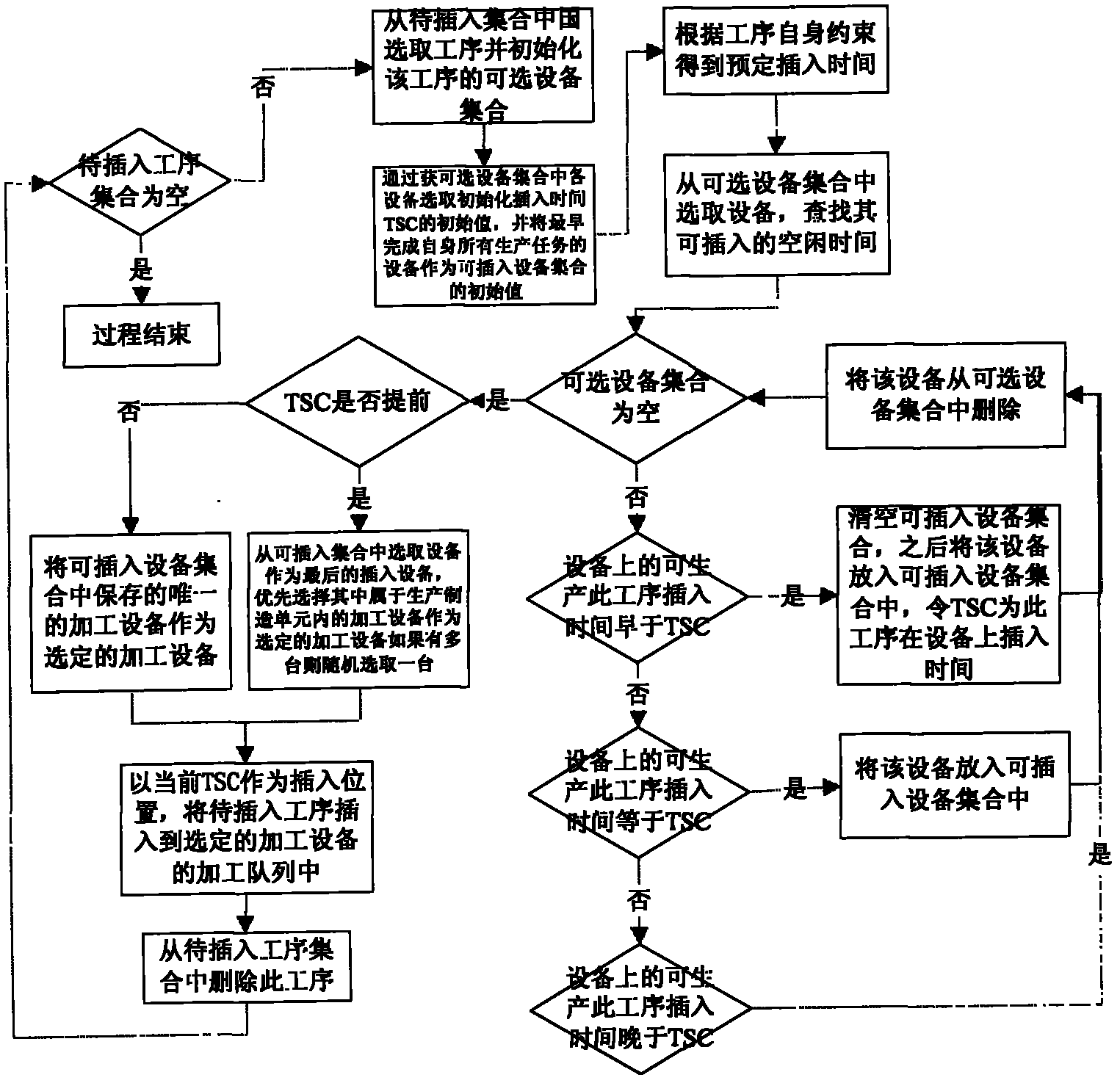

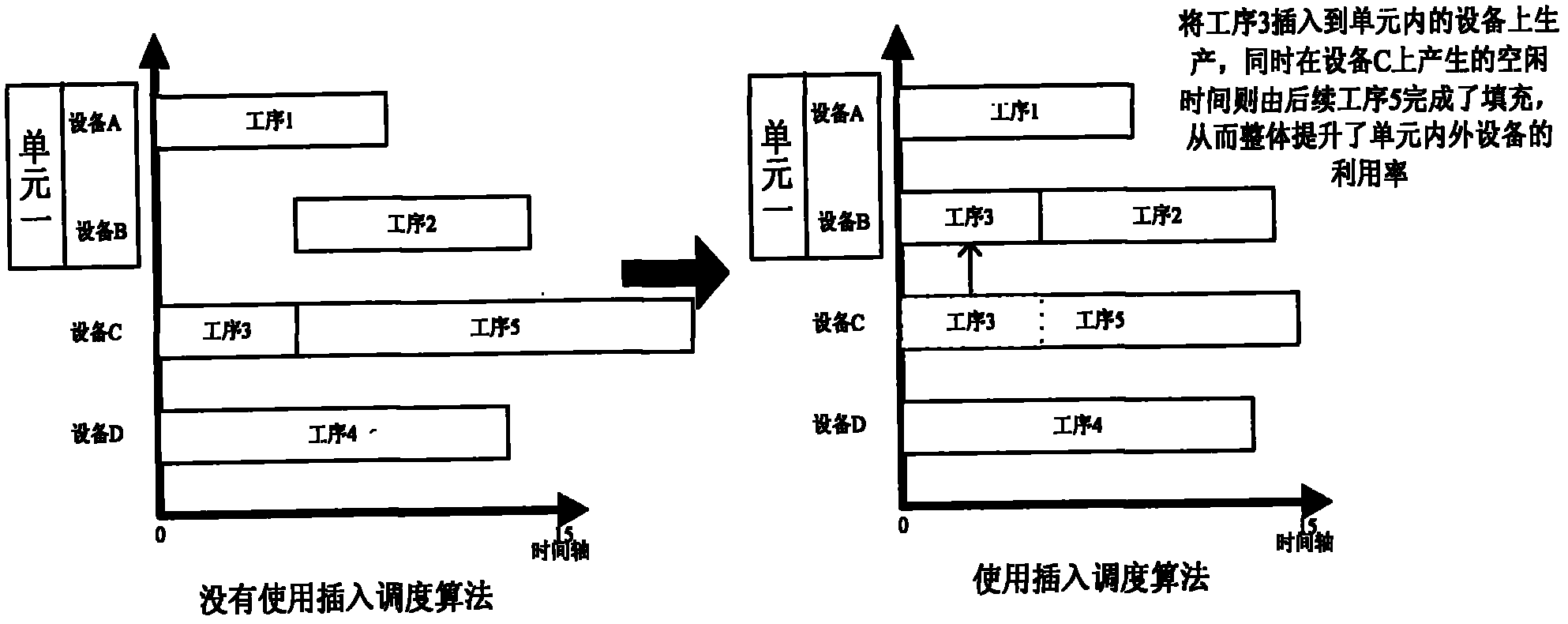

[0034] The overall flowchart of the insertion scheduling algorithm of the mixed-line production discrete process described in the present invention is as attached figure 1 shown. The beneficial effects of the present invention are as figure 2 As shown, after using the discrete process insertion scheduling algorithm, the overall equipment utilization rate in the mixed-line production has been improved.

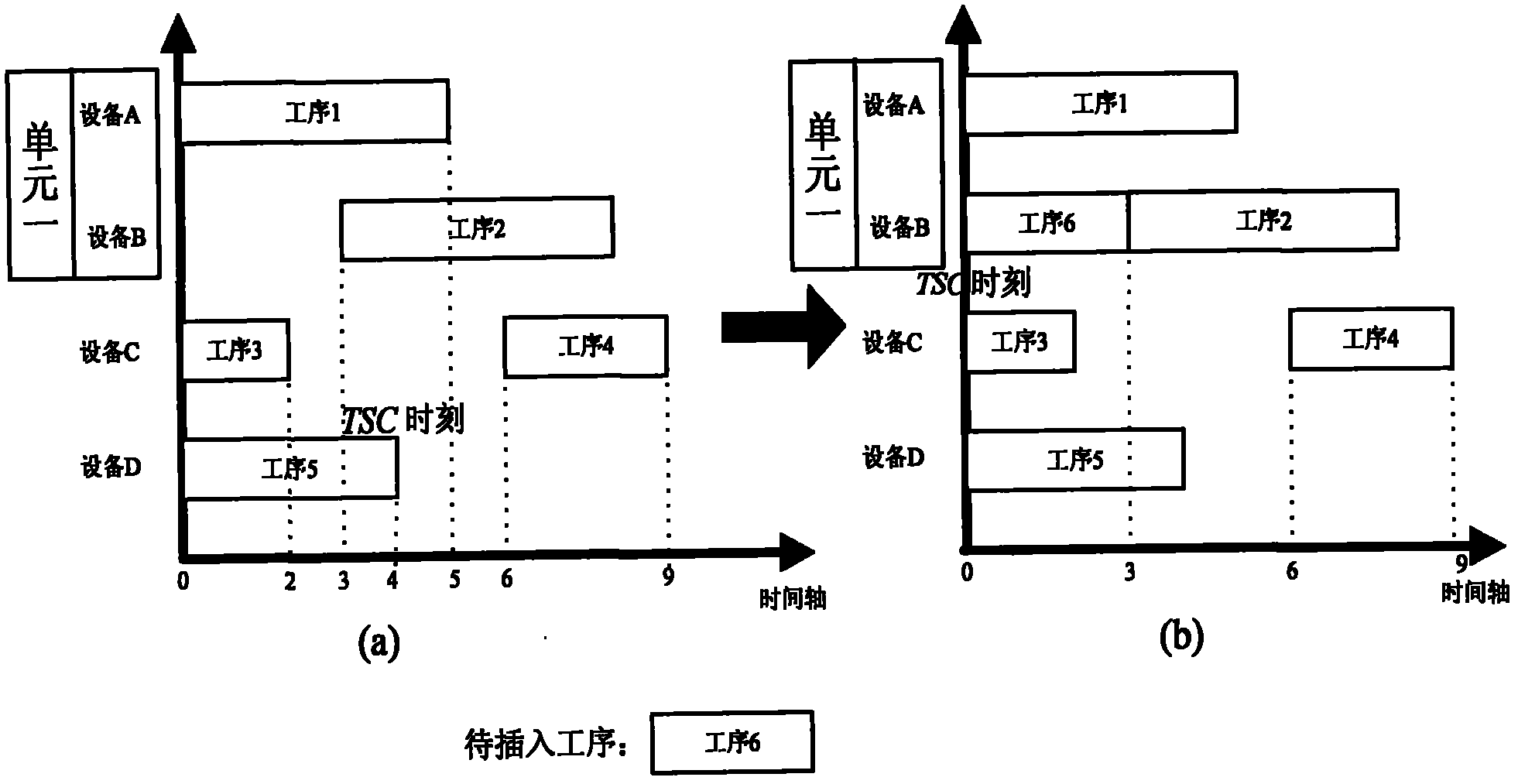

[0035] The specific implementation manners of the present invention will be explained below in conjunction with the technical solution embodiments and the accompanying drawings. See attached image 3 , the calculation method of the process to be inserted is analyzed as follows.

[0036] Such as image 3 As shown in (a), unit one includes equipment A and B, on which processes 1 and 2 have been arranged, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com