Suspension system for vehicle and tyre for vehicle

A technology for tires and vehicles, applied in vehicle parts, tire parts, tire tread/tread pattern, etc., to achieve the effect of reducing energy consumption and improving ground contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

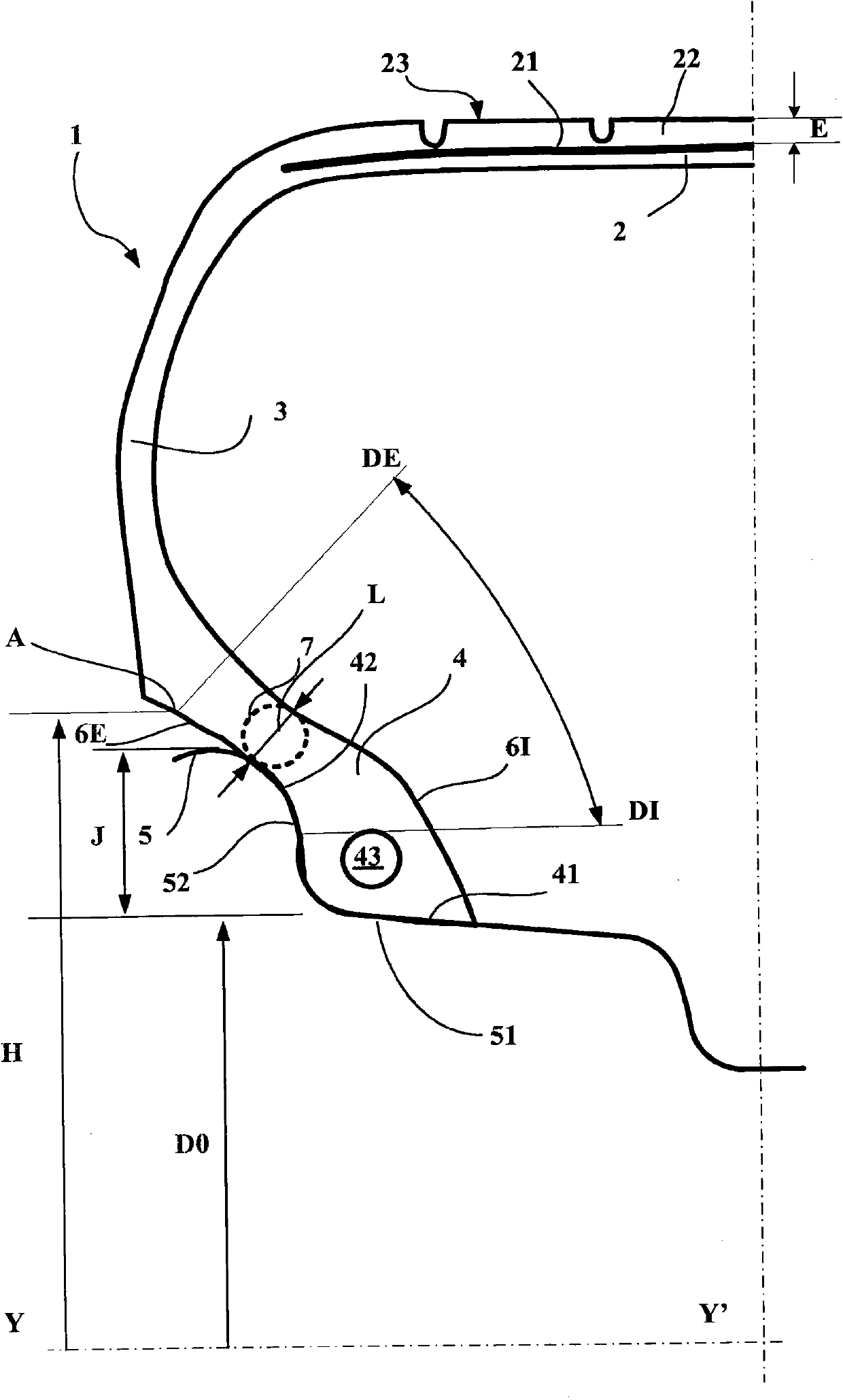

[0028] The single figure attached to this specification shows a partial view of a radial tire 1 used in a combination according to the invention, mounted on a mounting rim 5 and inflated to its normal operating pressure. Seen in a meridian section, ie in a plane containing the axis of rotation (YY'), the tire 1 comprises a bead 4 in contact with a mounting rim 5 extending radially outwards through a sidewall 3 terminating in the There are 2 crown parts.

[0029] The mounting rim 5 comprises a seat 51 inclined with respect to the direction of the axis of rotation YY' in order to press the bead seat 41 against it. The rim well 51 extends axially and radially outwards by a rim flange 52 against which the beads of the tire can be pressed. The nominal diameter (Do) of said rim is measured at the point where the rim well and the rim flange intersect according to the provisions of the E.T.R.T.O (European Tire and Rim Technical Organization) standard. The height (J) of the rim flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com