Packaging container for oa roller

A packaging container and shaft holding technology, applied in the field of packaging containers for OA rollers, can solve the problems of packaging workability, increase in conveying cost, and cost conveying cost, and achieve good workability, reduced conveying cost, and light container weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

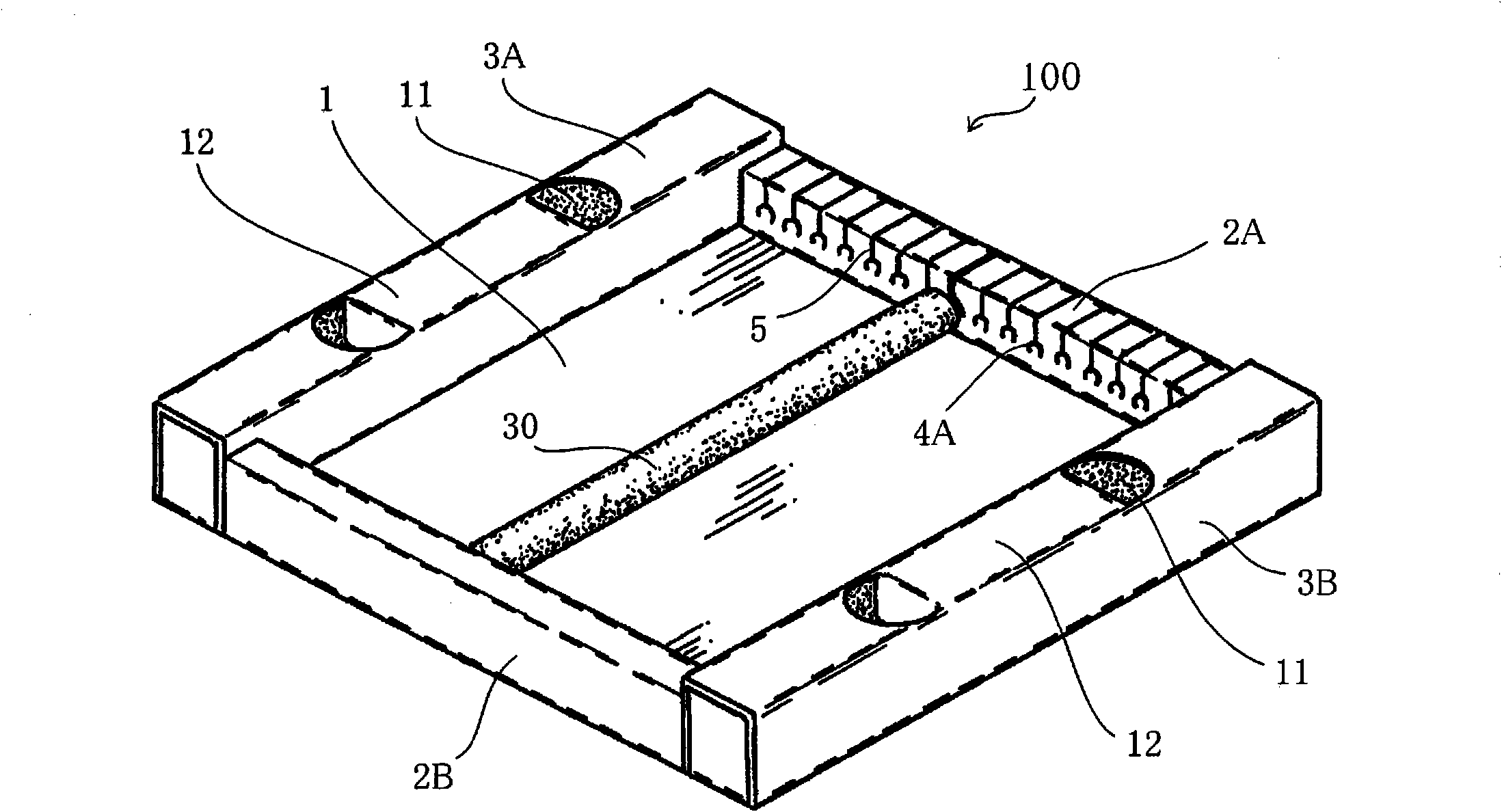

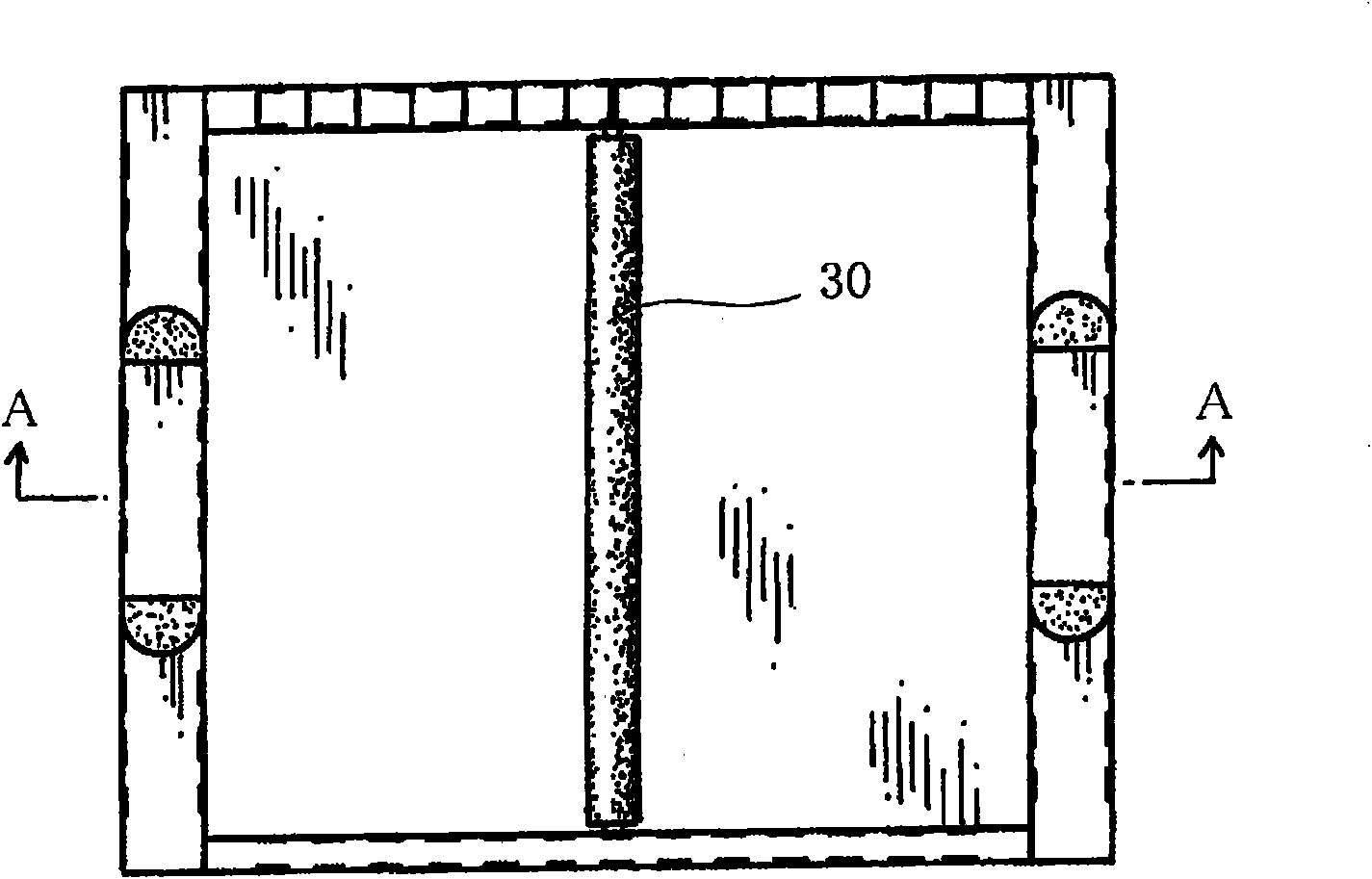

[0105] Made of corrugated paper (K5W) with figure 1 A box-shaped packaging container for OA rolls as shown. The number of OA rollers stored in one container was 15, and the height difference between the two pairs of erected parts was 3 mm.

Embodiment 2

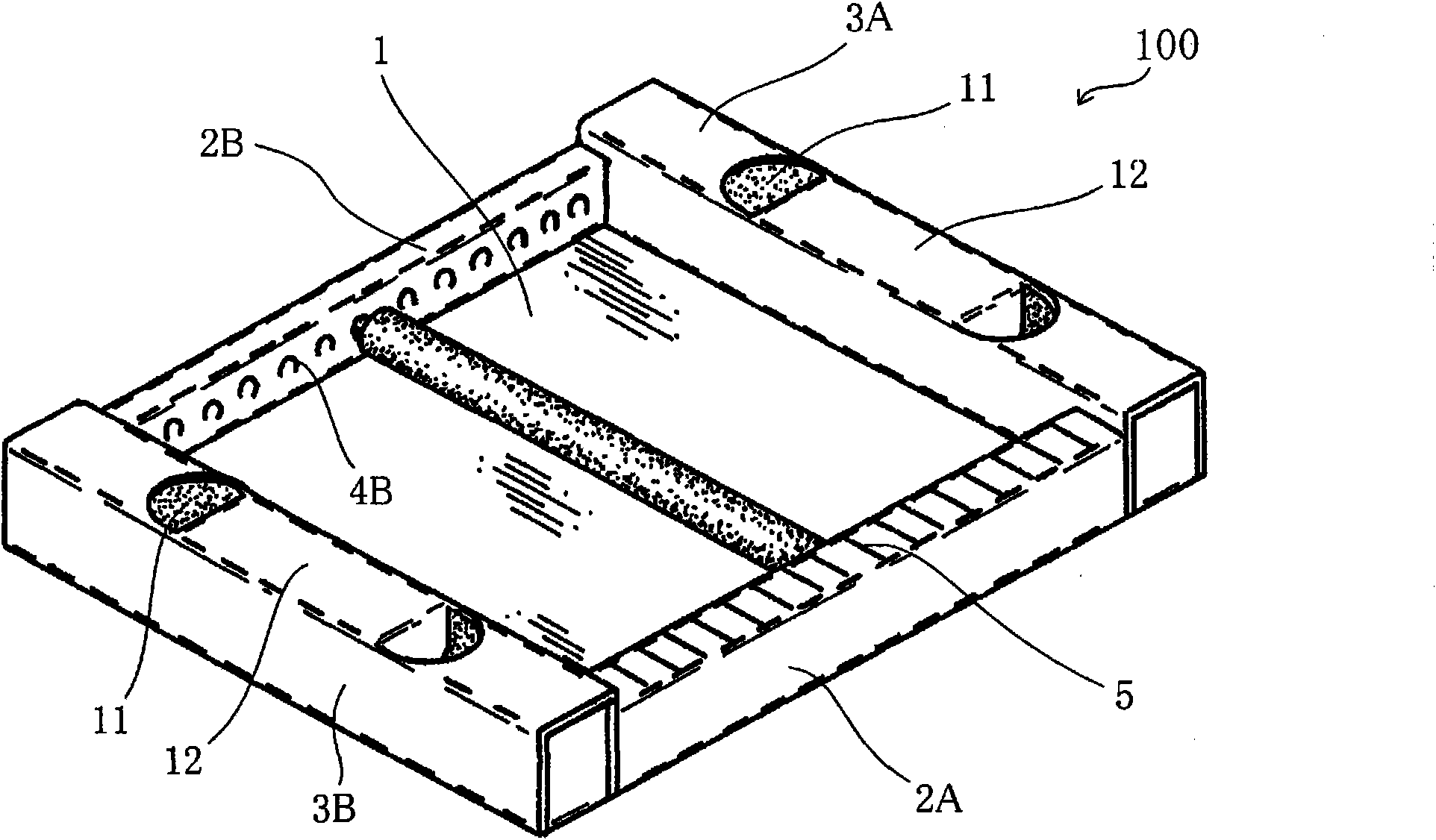

[0107] Made of corrugated paper (K5W) with Figure 7 A box-shaped packaging container for OA rolls as shown. The number of OA rollers stored in one container was 15, and the height difference between the two pairs of erected parts was 3 mm.

Embodiment 3

[0109] Made of corrugated paper (K5W) with Figure 21 A box-shaped packaging container for OA rolls as shown. The number of OA rollers stored in one container was 15, and the height difference between the two pairs of erected parts was 3 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com