Method for manufacturing carbon nanotube

A technology of carbon nanotubes and manufacturing methods, which is applied in the field of carbon nanotube manufacturing, can solve problems such as complex manufacturing processes of carbon nanotubes, and achieve the effect of low volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Hereinafter, the present invention will be described more specifically using examples. However, the present invention is not limited to these examples at all, and can be appropriately changed within a range that does not change the gist.

[0054]

[0055] Add 500 ml of water to 10 g of wollastonite (Nyglos No. 5, fiber diameter: 5 μm, fiber length: 50 μm), and stir well to prepare a dispersion slurry.

[0056] Add 5.4 μ nickel nitrate (reagent special grade) to 500 ml of water and dissolve. 0.7 g of ammonium molybdate (special grade reagent) was added to this solution and dissolved. This solution (catalyst liquid) was added to the above-mentioned slurry.

[0057] The slurry was stirred for 1 hour, left to stand, washed with water three times by decantation, and separated by filtration.

[0058] The obtained filter cake was dried at 120° C. for 1 hour, and ground with a mortar to obtain wollastonite carrying the catalyst.

[0059]

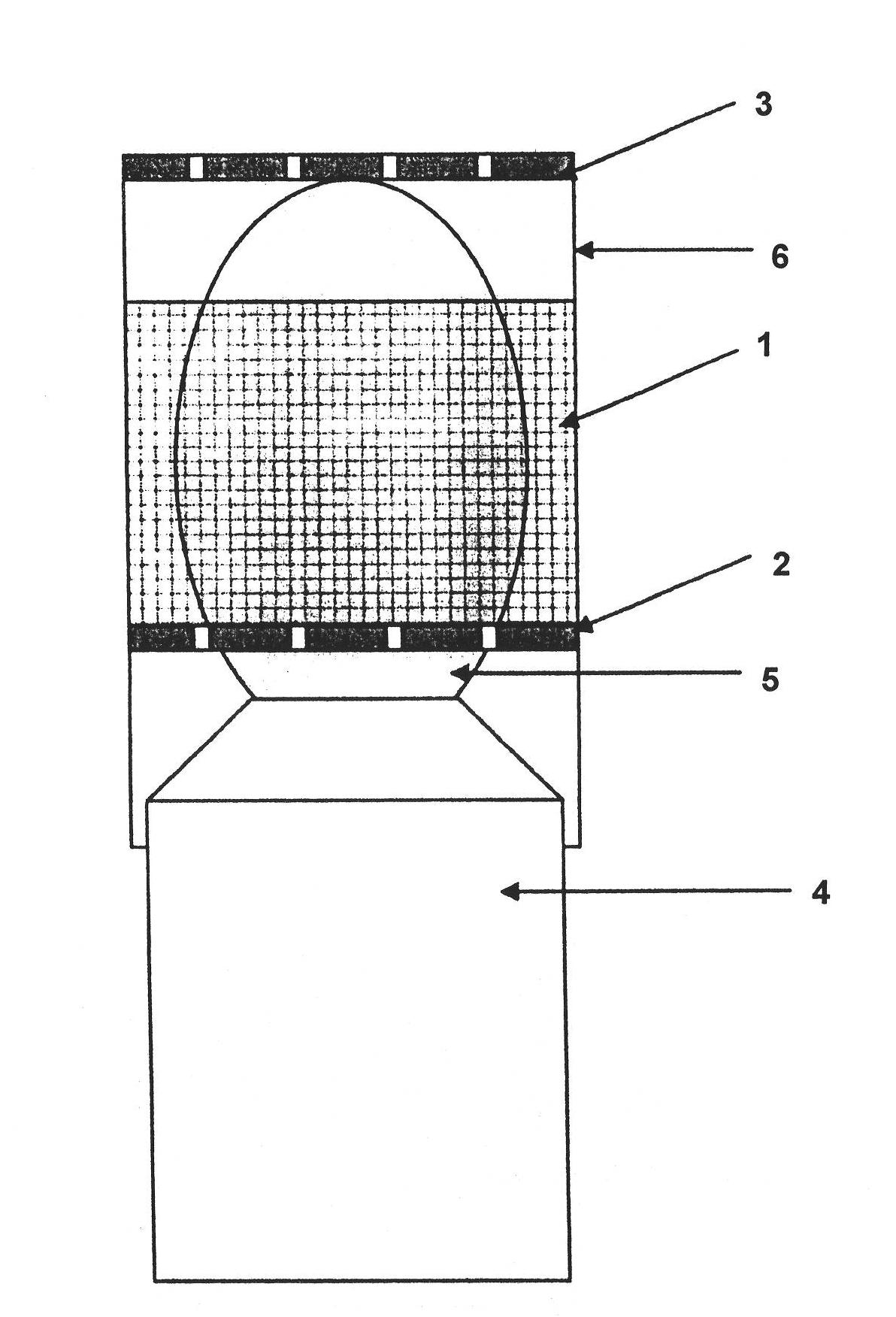

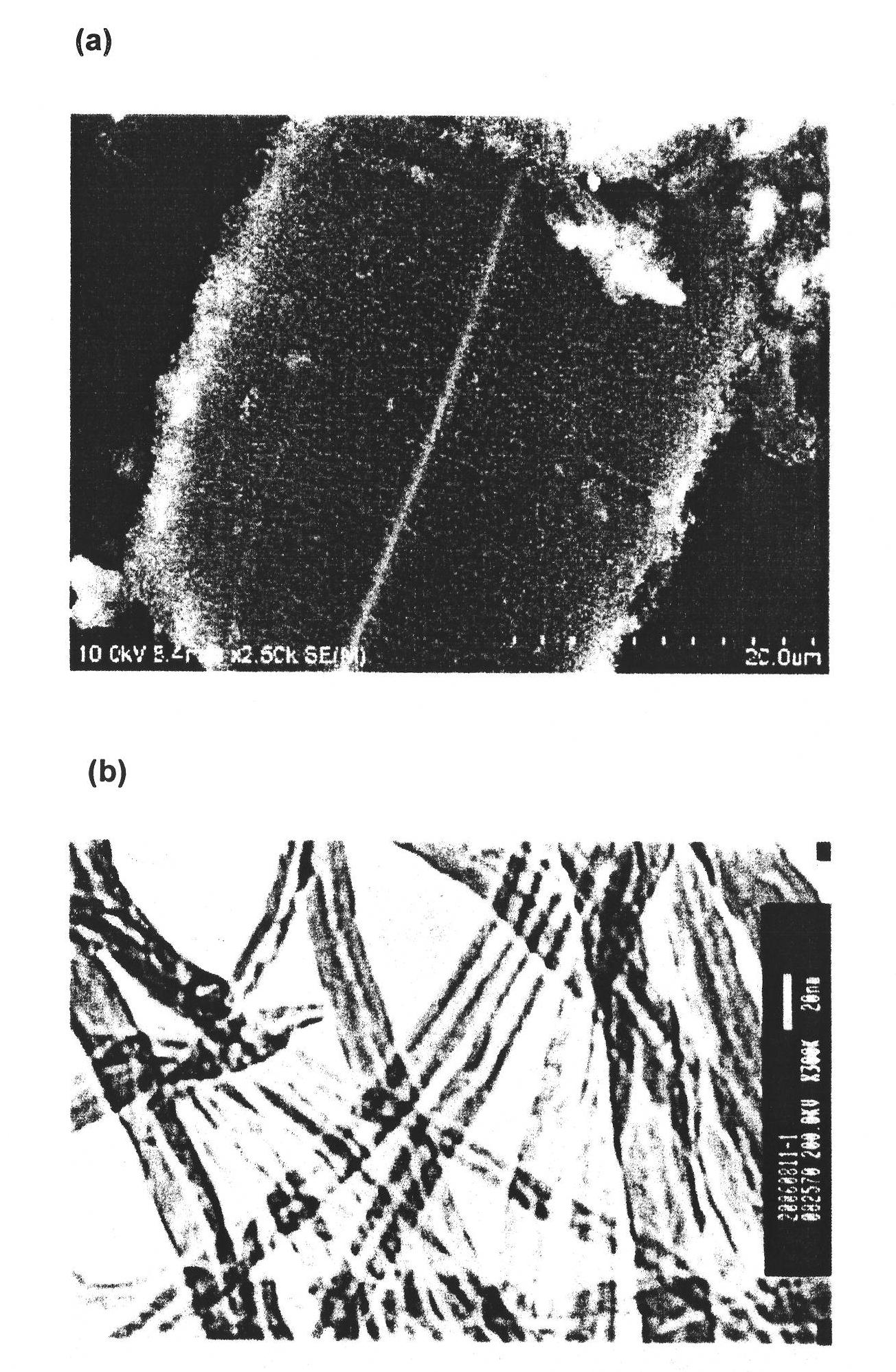

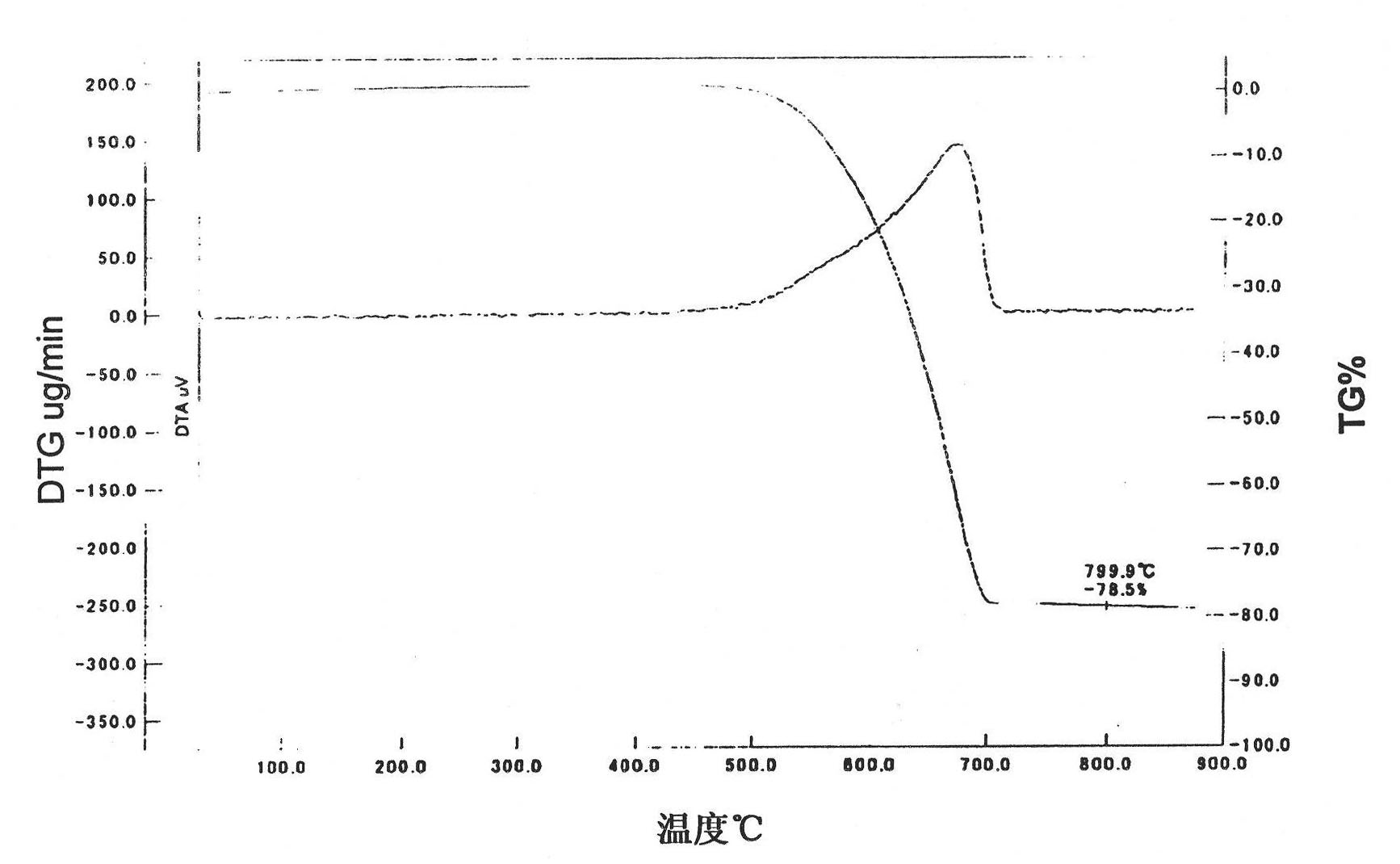

[0060] 0.5 g of the obtained wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com