Method for producing exhaust gas purification catalyst

A technology of exhaust gas purification and manufacturing method, which is applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of simple and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

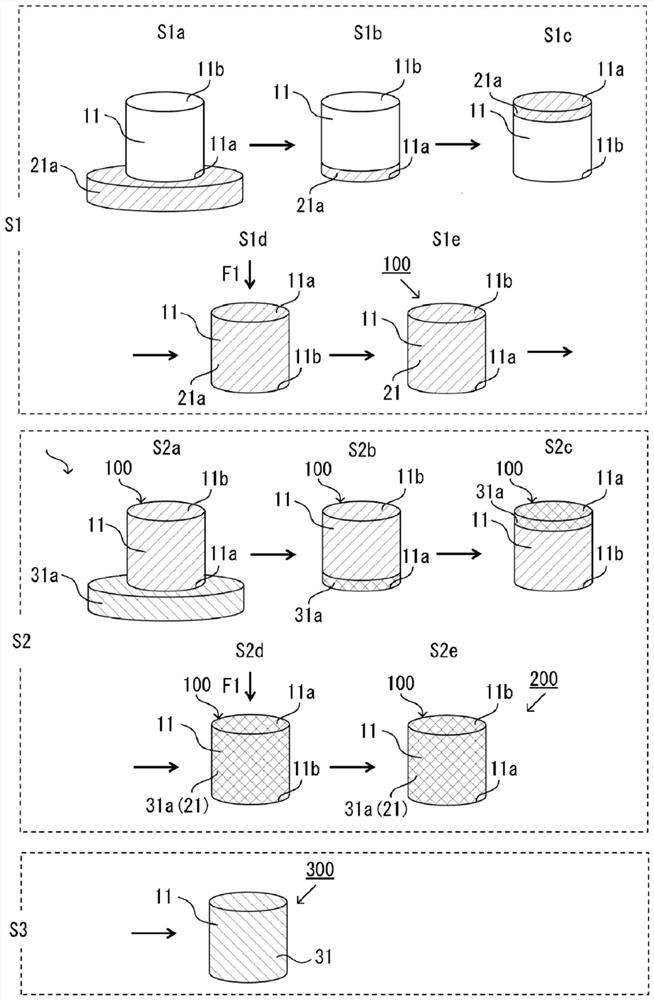

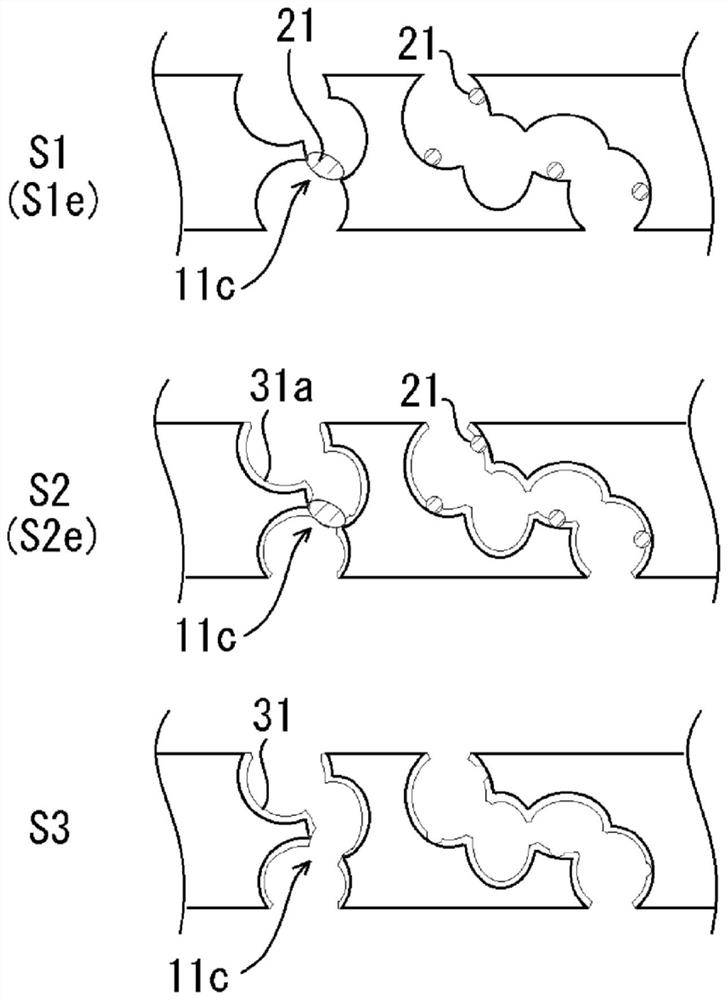

Method used

Image

Examples

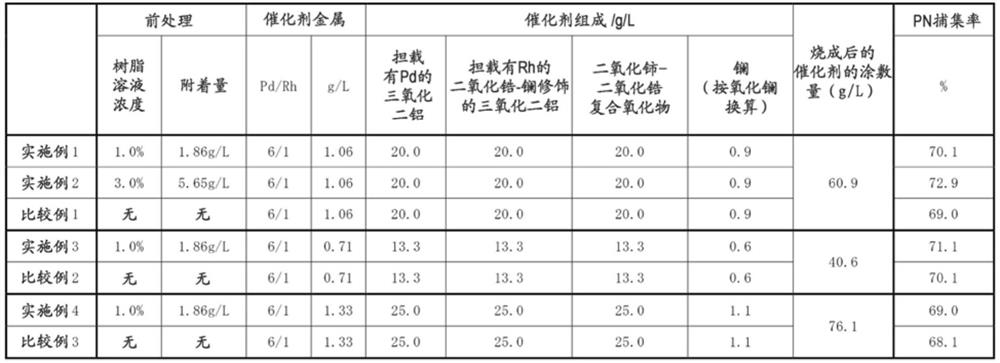

Embodiment 1

[0091] Polyvinyl alcohol (hereinafter referred to as "PVA") was mixed with ion-exchanged water to prepare a 1.0% by mass PVA aqueous solution. Next, a wall-flow type honeycomb substrate made of cordierite (number of cells / mil thickness: 300 cells / 8 mil, diameter: 118.4 mm, overall length: 127 mm) was prepared. The end of the substrate on the exhaust gas introduction side was immersed in the above-mentioned PVA aqueous solution, and vacuum suction was performed from the opposite end to impregnate and hold the PVA aqueous solution in the substrate. Introduce gas vertically downward into the substrate from the end face side impregnated and held with the PVA aqueous solution, apply the PVA aqueous solution to the surface inside the pores of the partition wall of the substrate, and blow off the excess from the end of the gas discharge side. Amount of PVA aqueous solution. At this time, blowing was performed until the PVA aqueous solution no longer came out from the gas discharge s...

Embodiment 2

[0096] An exhaust gas purification catalyst was produced in the same manner as in Example 1, except that PVA and ion-exchanged water were mixed to prepare and use a 3.0% by mass PVA aqueous solution.

Embodiment 3

[0098] The coating of the catalyst slurry was performed in the same manner as in Example 1 except that the coating amount of the catalyst after firing was 40.6 g (excluding the mass of the platinum group metal) per 1 L of the substrate. Exhaust gas purification catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com