Method for manufacturing carbon nanotube

一种碳纳米管、制造方法的技术,应用在碳纳米管的制造领域,能够解决碳纳米管制造工序复杂等问题,达到体积密度低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Hereinafter, the present invention will be described more specifically using examples. However, the present invention is not limited to these examples at all, and can be appropriately changed within a range that does not change the gist.

[0054]

[0055] Add 500 ml of water to 10 g of wollastonite (Nyglos No. 5, fiber diameter: 5 μm, fiber length: 50 μm), and stir well to prepare a dispersion slurry.

[0056] Add 5.4 μ nickel nitrate (reagent special grade) to 500 ml of water and dissolve. 0.7 g of ammonium molybdate (special grade reagent) was added to this solution and dissolved. This solution (catalyst liquid) was added to the above-mentioned slurry.

[0057] The slurry was stirred for 1 hour, left to stand, washed with water three times by decantation, and separated by filtration.

[0058] The obtained filter cake was dried at 120° C. for 1 hour, and ground with a mortar to obtain wollastonite carrying the catalyst.

[0059]

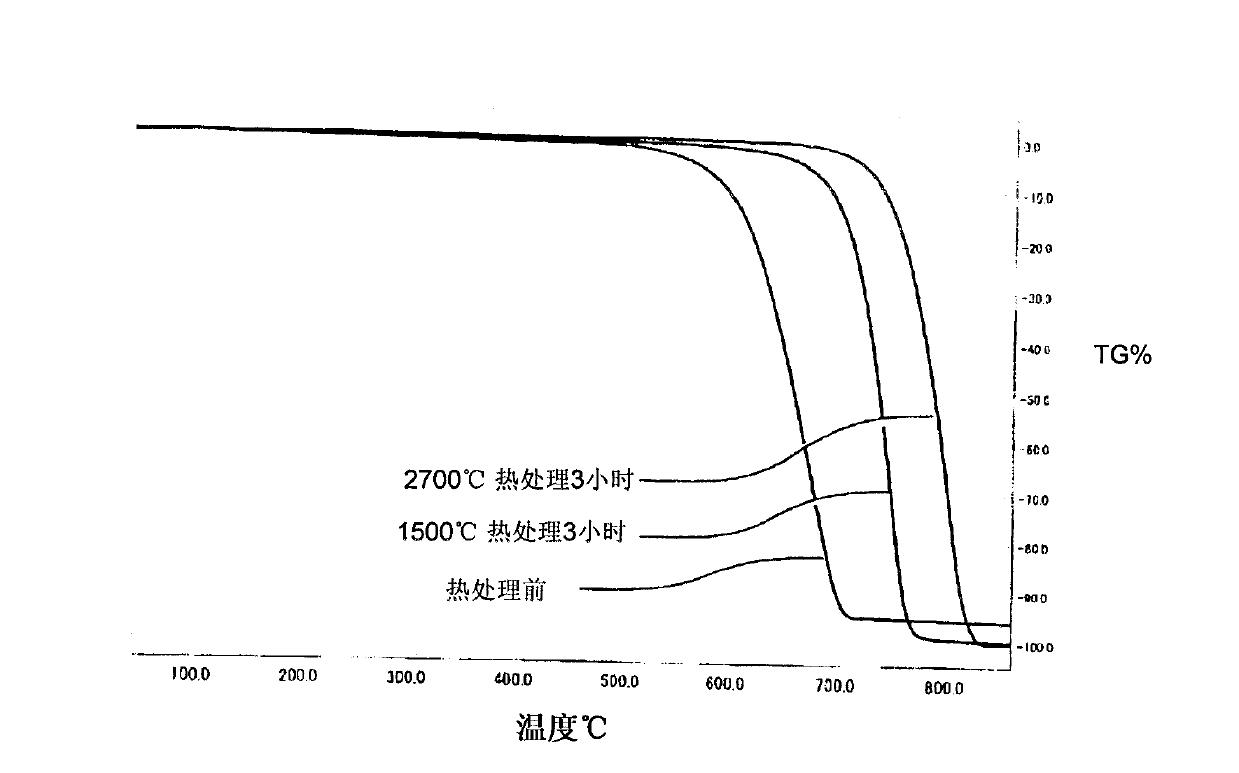

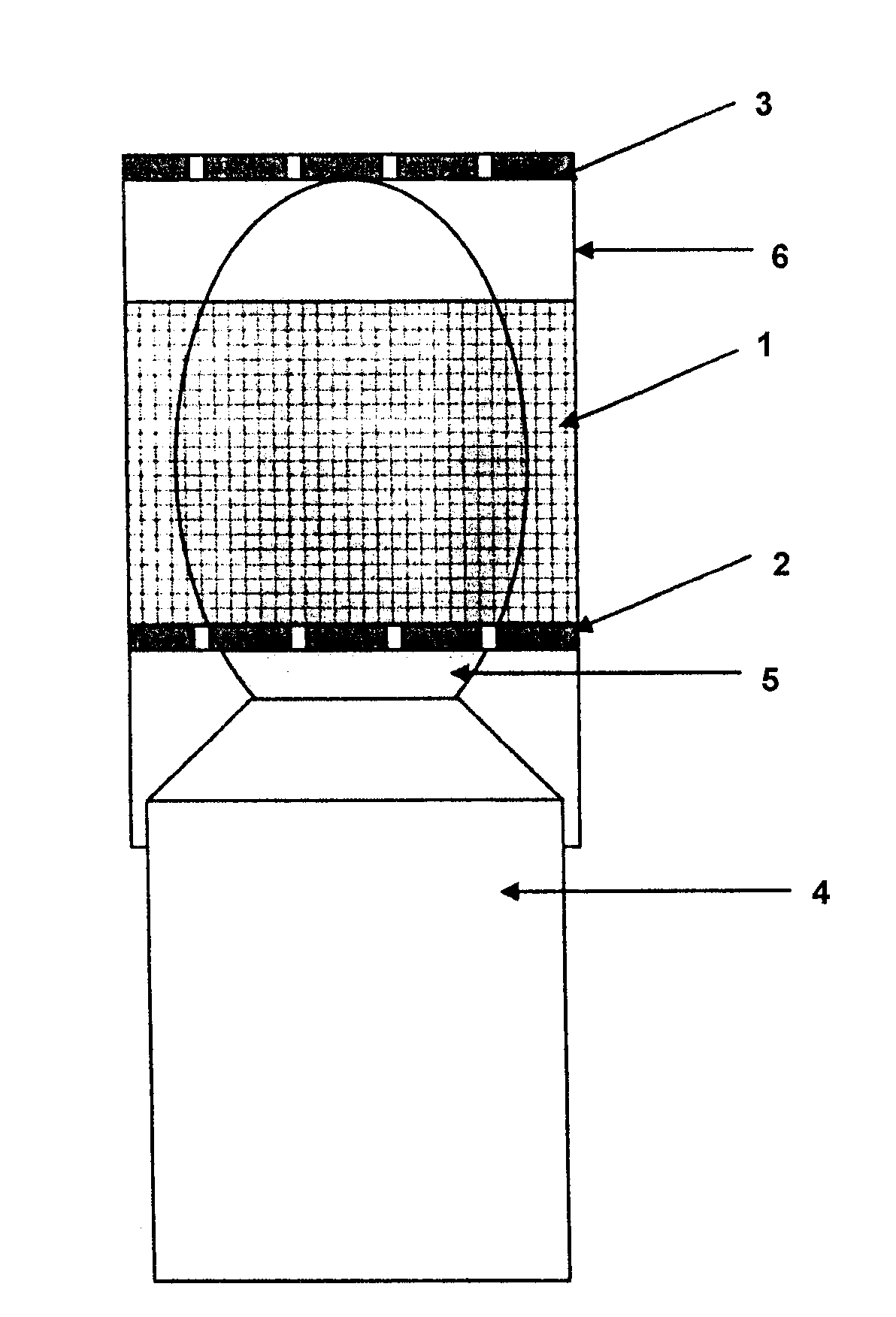

[0060] 0.5 g of the obtained wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com