Electrical tester setup and calibration device

A test device, electronic test technology, applied in the direction of measuring devices, manufacturing measuring instruments, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

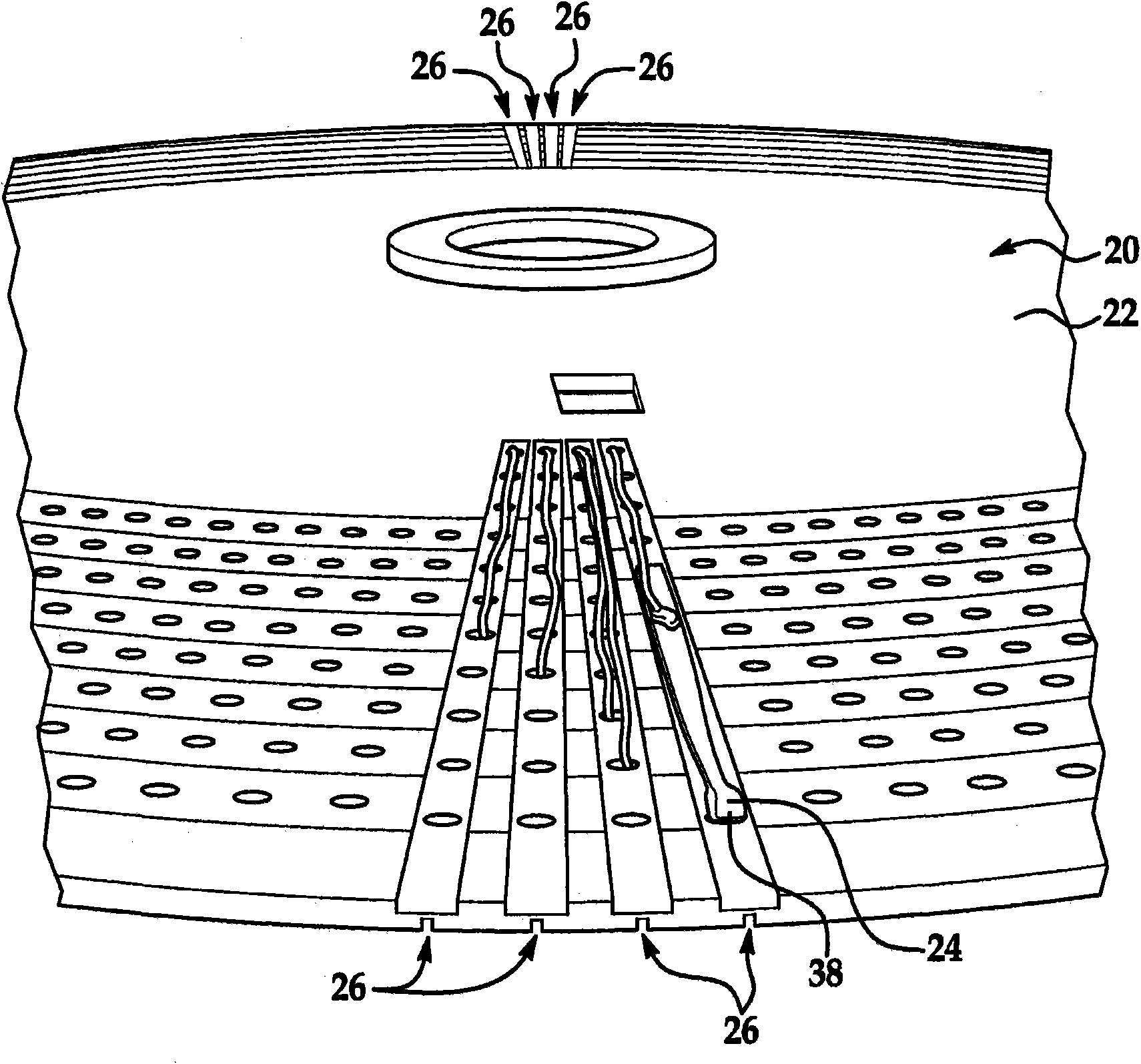

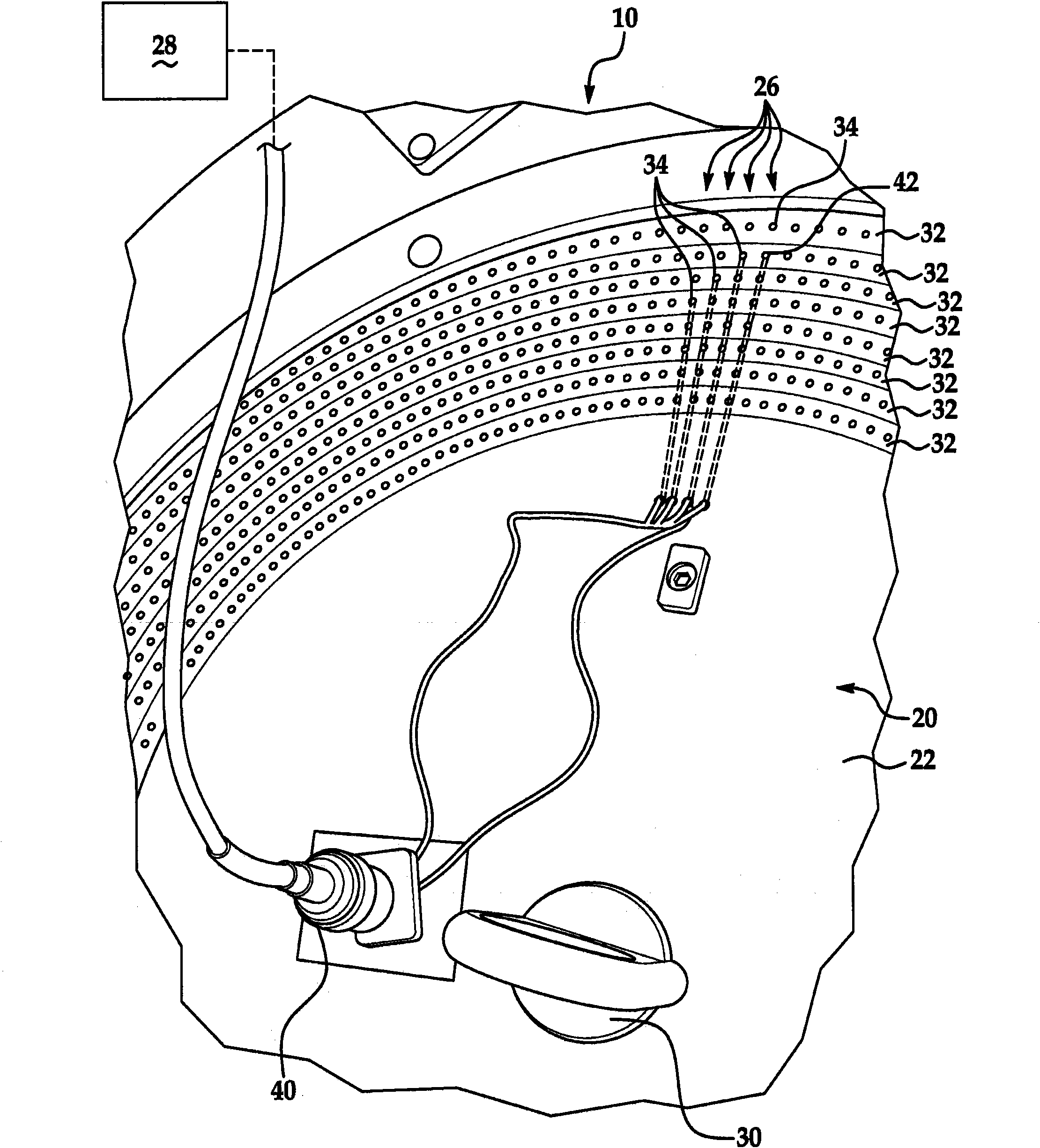

[0017] see briefly Figure 6 and Figure 7 , the electronic testing machine 10 has at least one upper contact 14 and at least one lower contact 16 of the test module 12 . Each test module 12 is positionable on angularly spaced radial lines extending from an associated central axis and has a plurality of contact pairs 14, 16 for testing electronic components. The production test plate or disc 50 includes a plurality of pockets 52 . Each pocket 52 can carry an electronic component 54 to the test location 26 for electrical insertion between the upper contacts 14 and the lower contacts 16 of the test module 12 of the electronic testing machine 10 to perform a test on the electronic component 54. or more than one test. The test board 50 is rotated about the central axis to transfer the electronic assemblies 54 to and from the test locations 26 associated with the corresponding upper contacts 14 and lower contacts 16 of the different test modules 12 . It should be understood tha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap