Pressure-actuated member, in particular paint pressure controller or coating agent valve

A technology of pressure regulator and pressure regulation, which is applied in the direction of fluid pressure control, control/regulation system, auxiliary non-electric fluid pressure control, etc., and can solve problems such as the separate sealing device of the supply valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

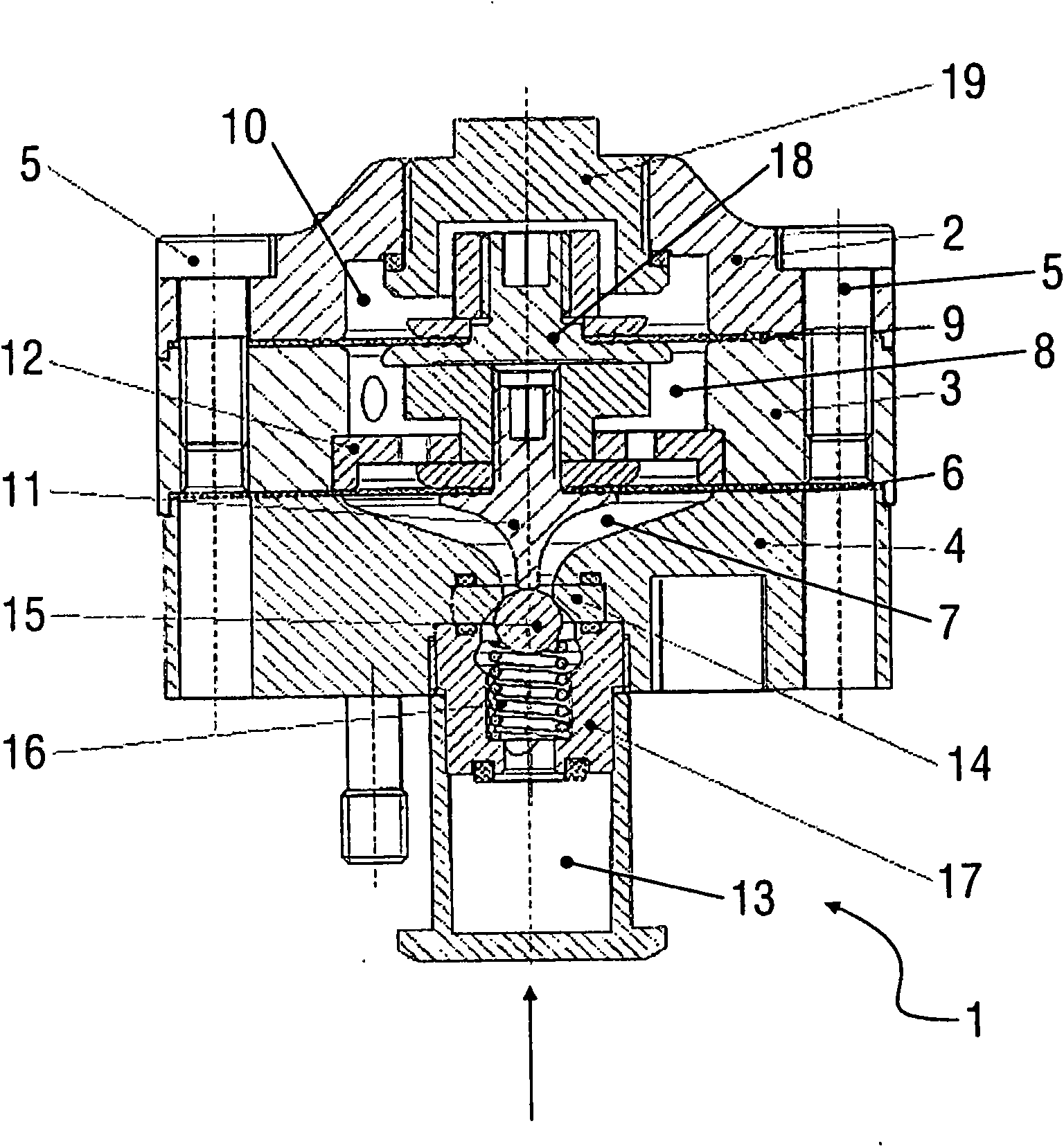

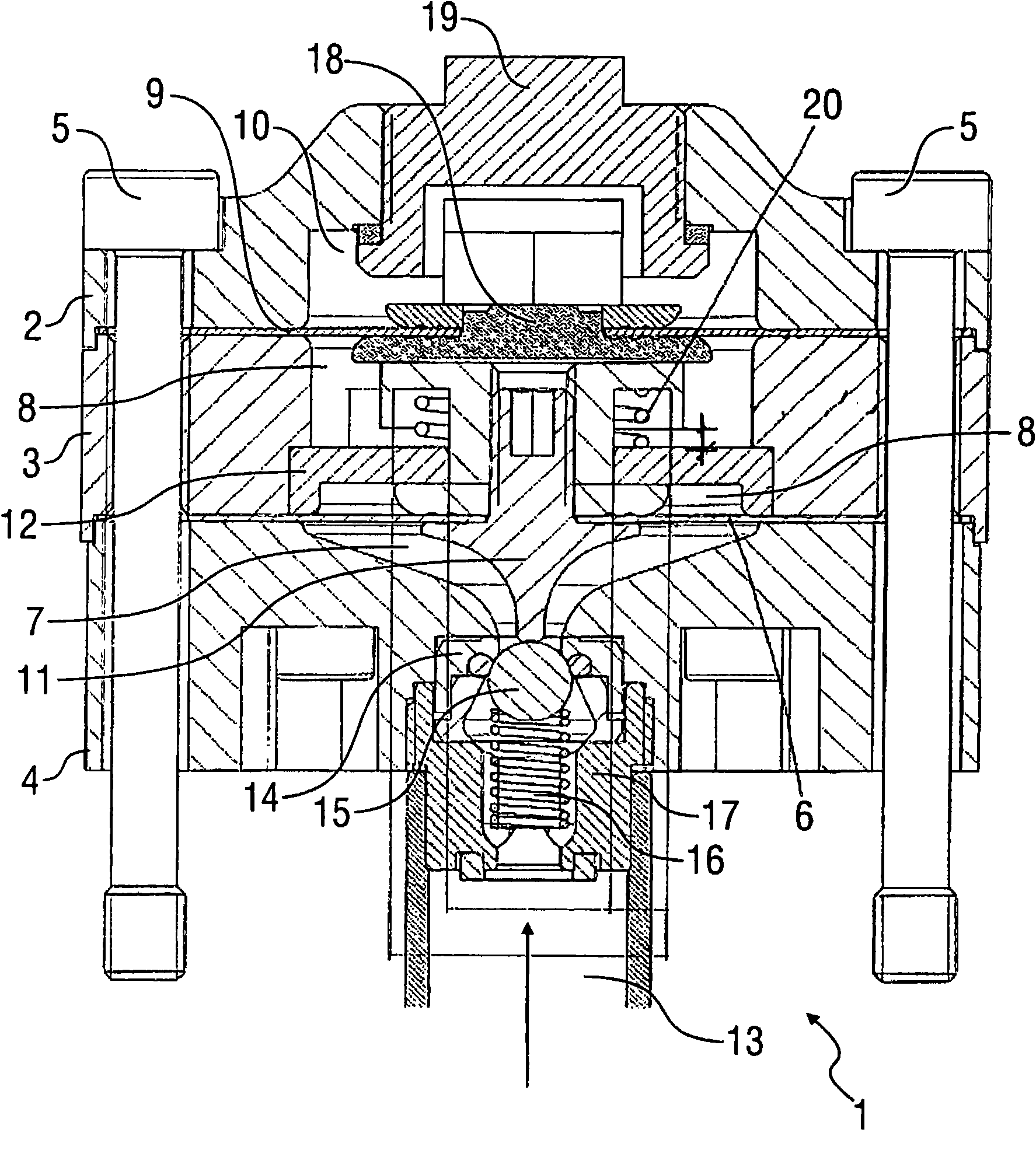

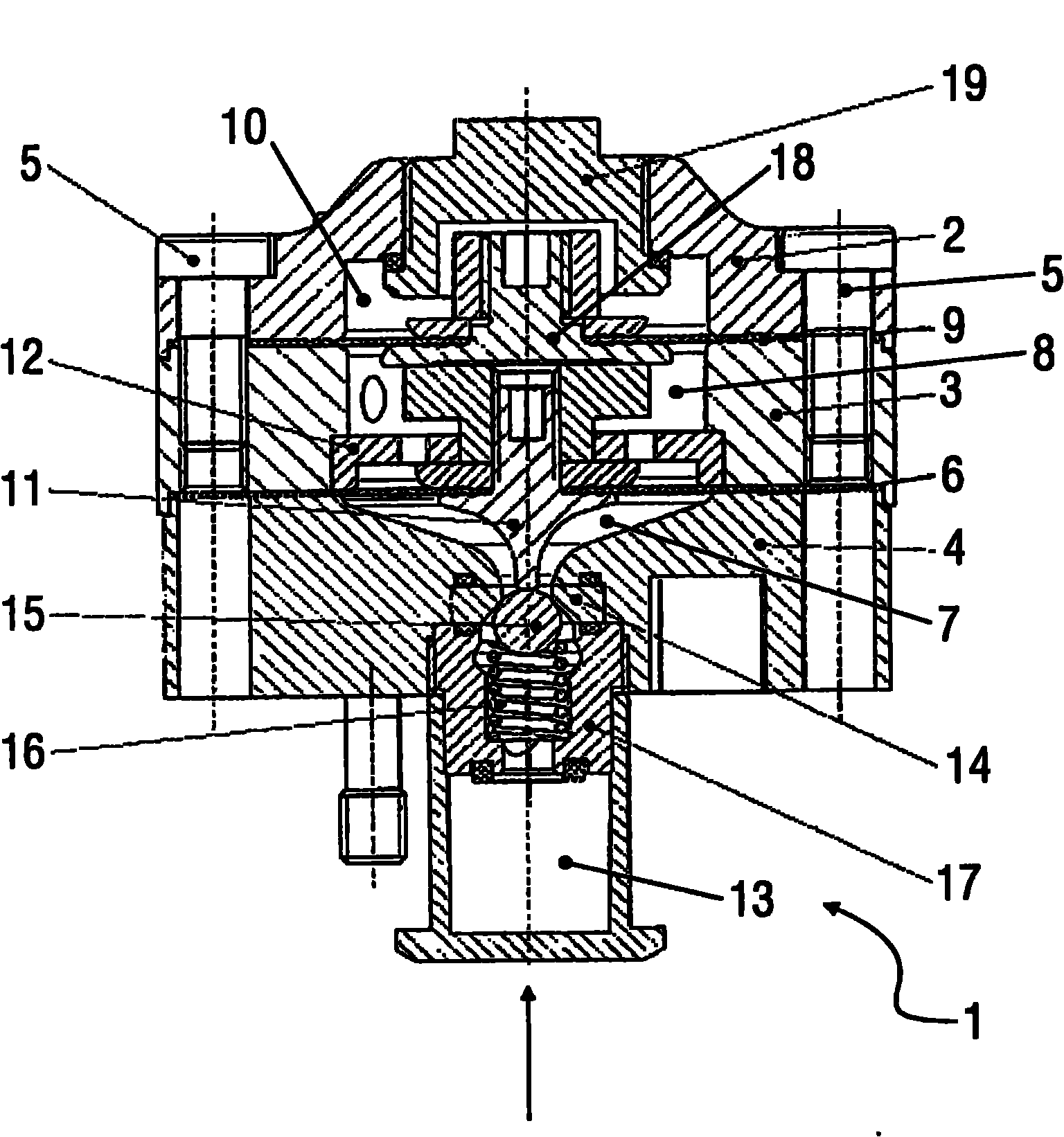

[0036] figure 1 A paint pressure regulator 1 according to the invention is shown for regulating the pressure of a paint medium in a paint system.

[0037] The paint pressure regulator 1 largely corresponds to the conventional paint pressure regulator described, for example, in patent application EP1376289A1, so that the contents of said patent application with regard to the structure and the mode of function of the paint pressure regulator 1 All are included in this manual.

[0038] Paint pressure regulator 1 has three housing parts 2 , 3 , 4 placed one above the other, which are fixedly connected to one another by screws 5 .

[0039]Between the housing part 3 and the housing part 4 there is a membrane 6 made of ceramic fiber composite material, wherein the membrane 6 separates the paint chamber 7 from the control air chamber 8 .

[0040] Between the housing part 2 and the housing part 3 there is a further diaphragm 9 which is also made of ceramic fiber composite material an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com