Elastic supporting structure of single-phase generator

A single-phase generator and elastic support technology, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of motor vibration becoming larger, and achieve the effect of simple structure and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

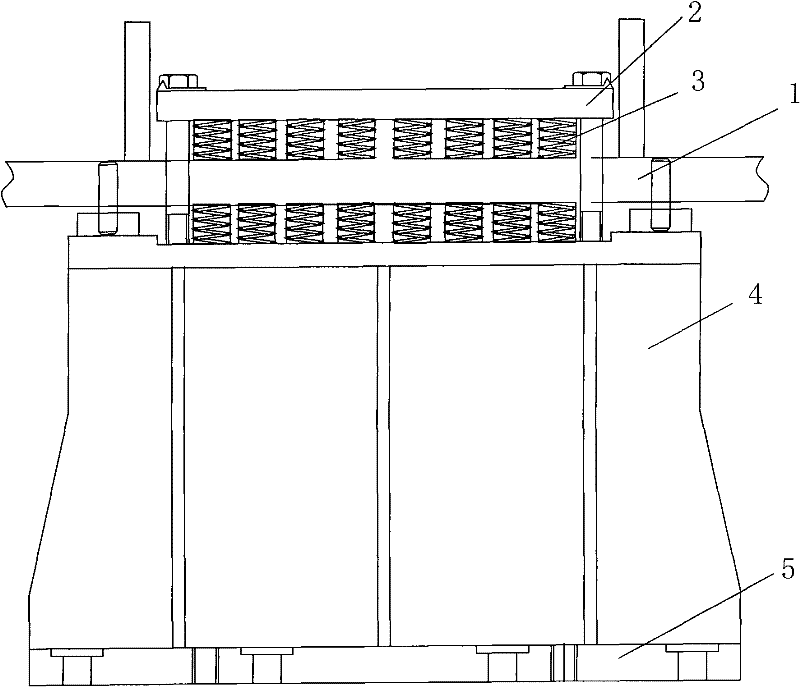

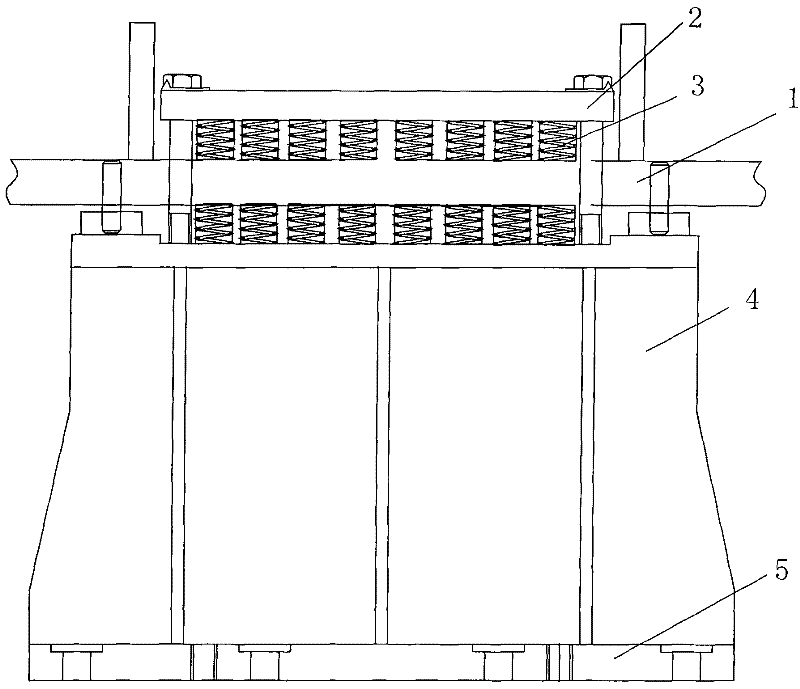

[0009] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] The present invention comprises motor frame protruding part 1, support 4, spring 3 and pressing plate 2, motor frame protruding part 1 belongs to a part of frame, is consistent with the movement of frame, and its upper and lower sides are all processed smoothly. The support 4 is located between the foundation floor 5 and the extension part 1 of the motor base, and the support 4 and the base floor 5 are fixedly connected. There is too much axial and side-to-side movement. The pressing plate 2 is arranged on the top of the extension part 1 of the motor base. The spring 3 is installed between the top and bottom of the extension part 1 of the motor base, the support 4 and the pressing plate 2 . Absorbs the energy of the machine base vibration. The consistency requirements of the spring 3 are relatively high, so that the elastic deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com