Device and method for balancing pressure in a turbojet bearing housing

A technology of turbojet and balancing device, applied in the direction of engine lubrication, jet propulsion device, gas turbine device, etc., can solve problems such as damage and rapid wear of seals, and achieve the effect of reducing weight, size and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

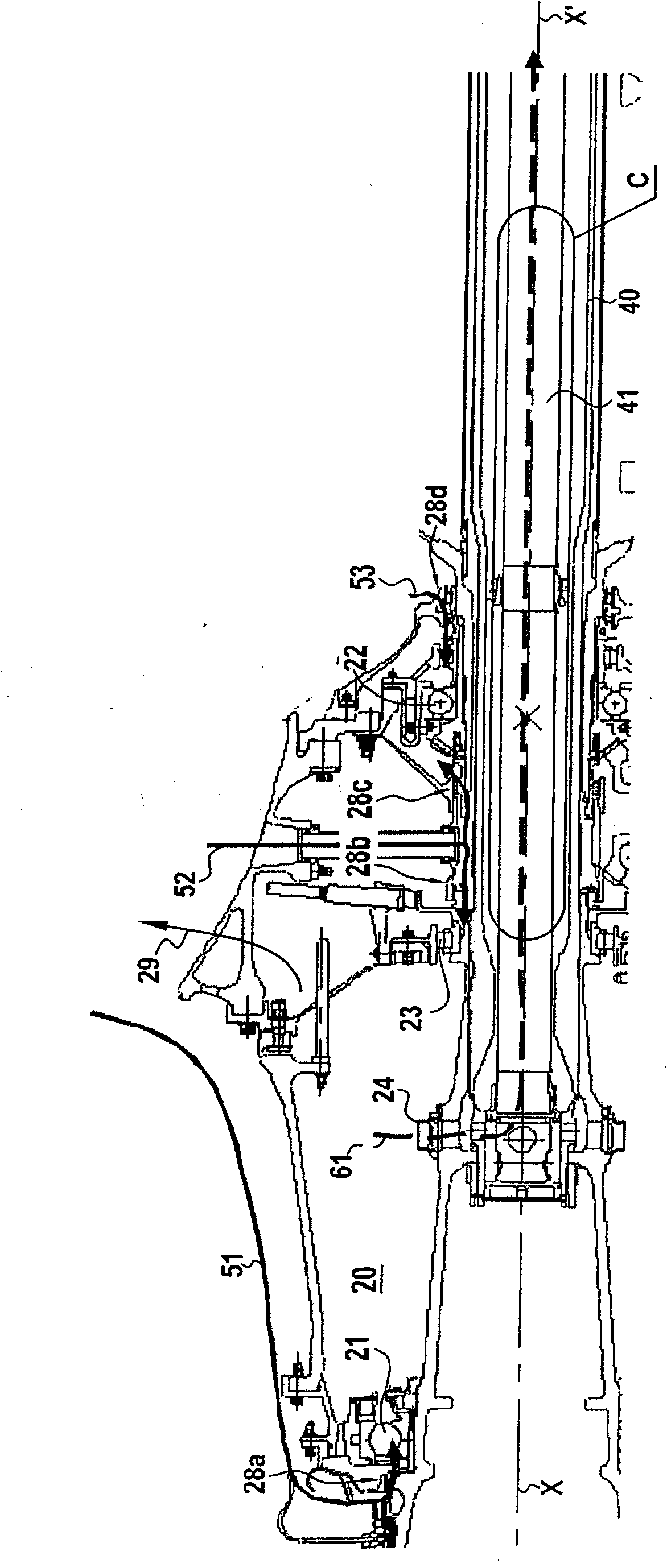

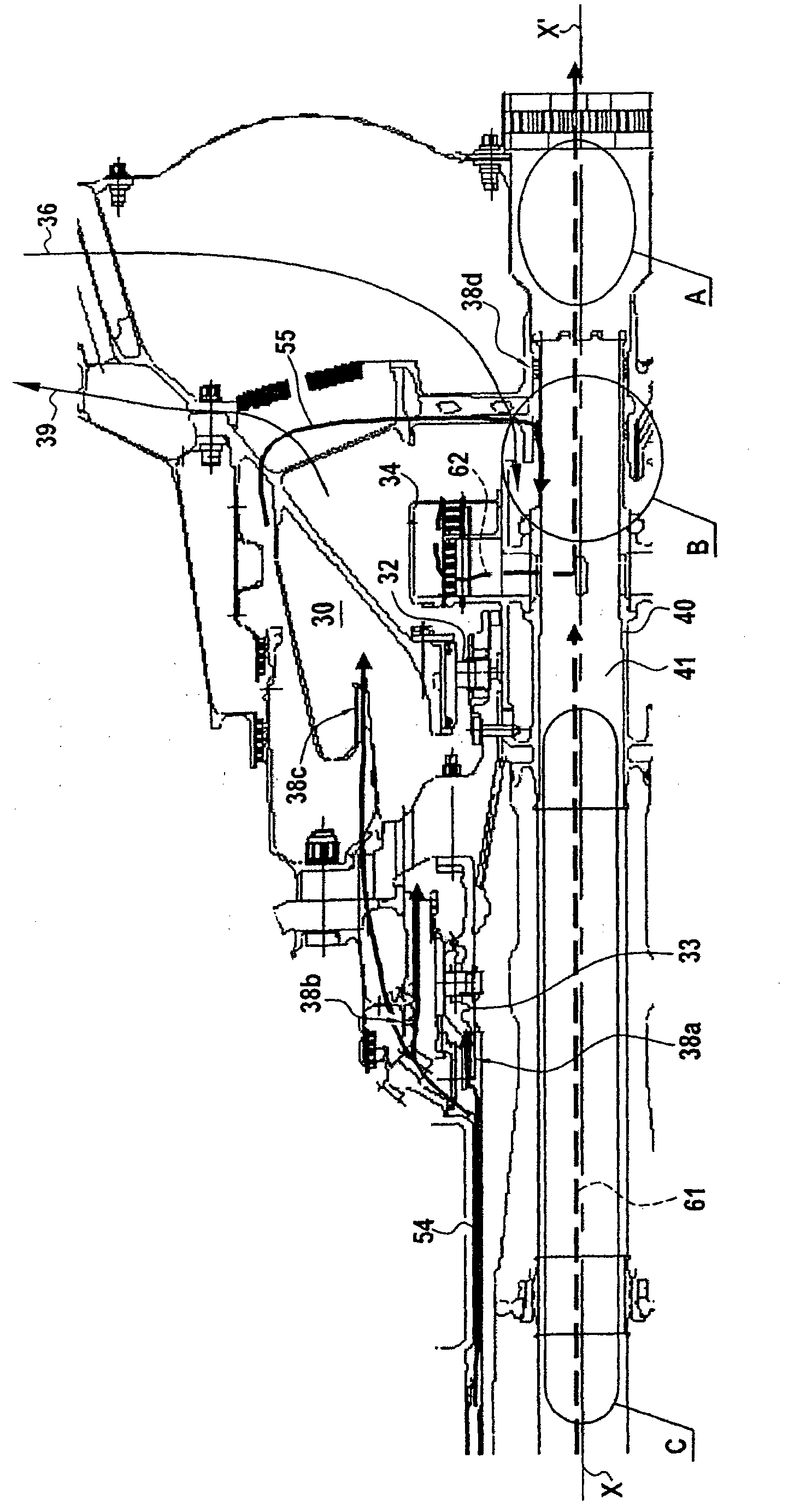

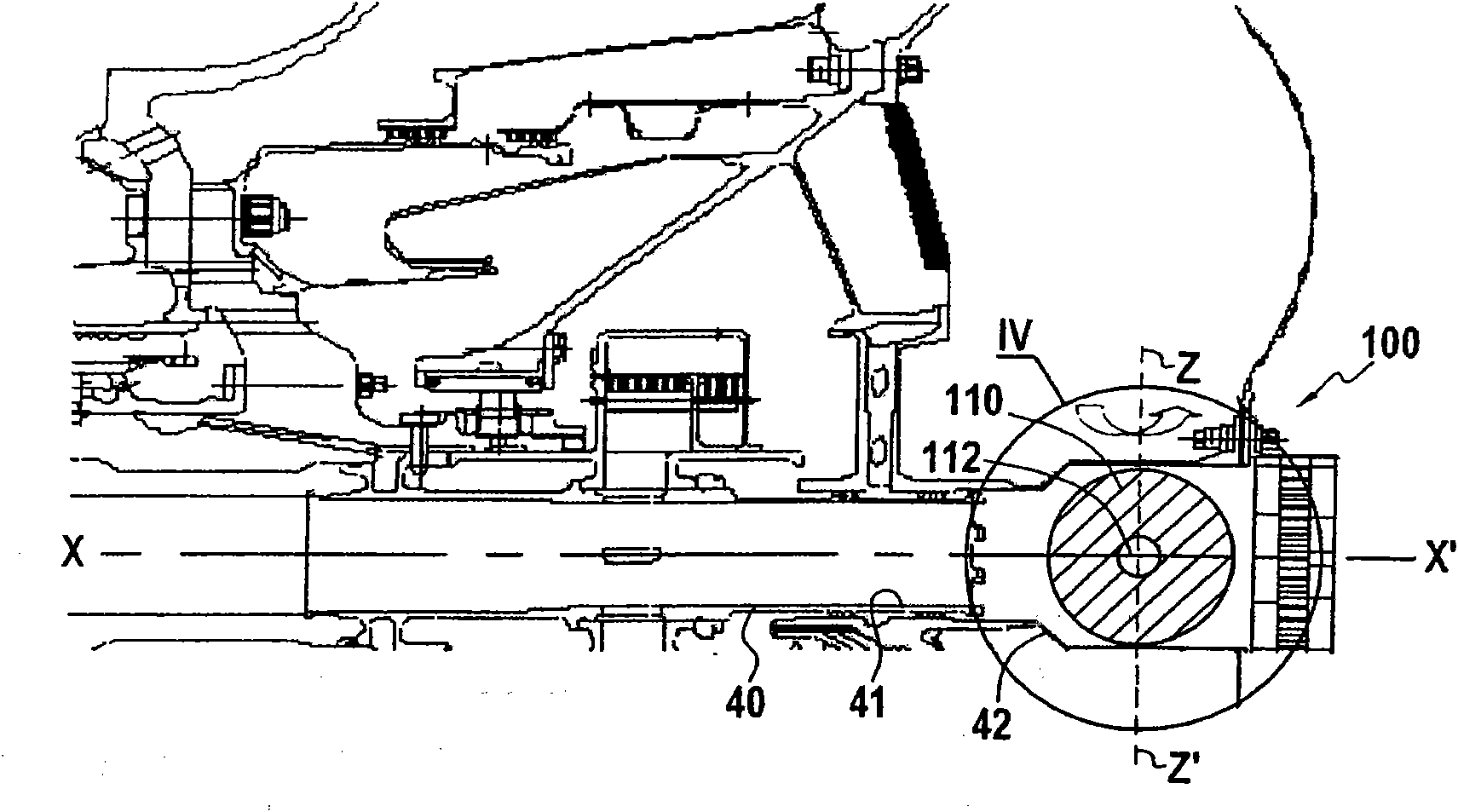

[0049] figure 1 with figure 2 The front casing 20 with the front bearings 21 , 22 and 23 and the rear casing 30 with the rear bearings 32 and 33 of the turbojet engine are shown respectively. As far as these housings are concerned, the low pressure rotor 40 includes ducts 41 to remove air and a portion of the lubricating oil entrained by the air and not trapped by the degreaser, this mixture flows through the front housing 20 and the rear housing 30 .

[0050] The position of these front and rear casings 20 and 30 in the turbojet engine is as follows Figure 14 shown.

[0051] More precisely, as figure 1 As shown, the boost line delivers three lines (arrows 51 , 52 and 53 shown in solid lines) of boost air from the drive airflow to the front housing 20 while the front housing 20 receives lubricating oil via nozzles.

[0052] This lubricating oil is mainly removed via a line that recovers the lubricating fluid (arrow 29 ) from the front housing 20 .

[0053] The chimney d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com