Vibration-damping device

A technology for anti-vibration devices and mounting components, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., and can solve problems such as unstable characteristics, compression deformation of separation components, and reduced sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the anti-vibration device of the present invention will be described based on the drawings.

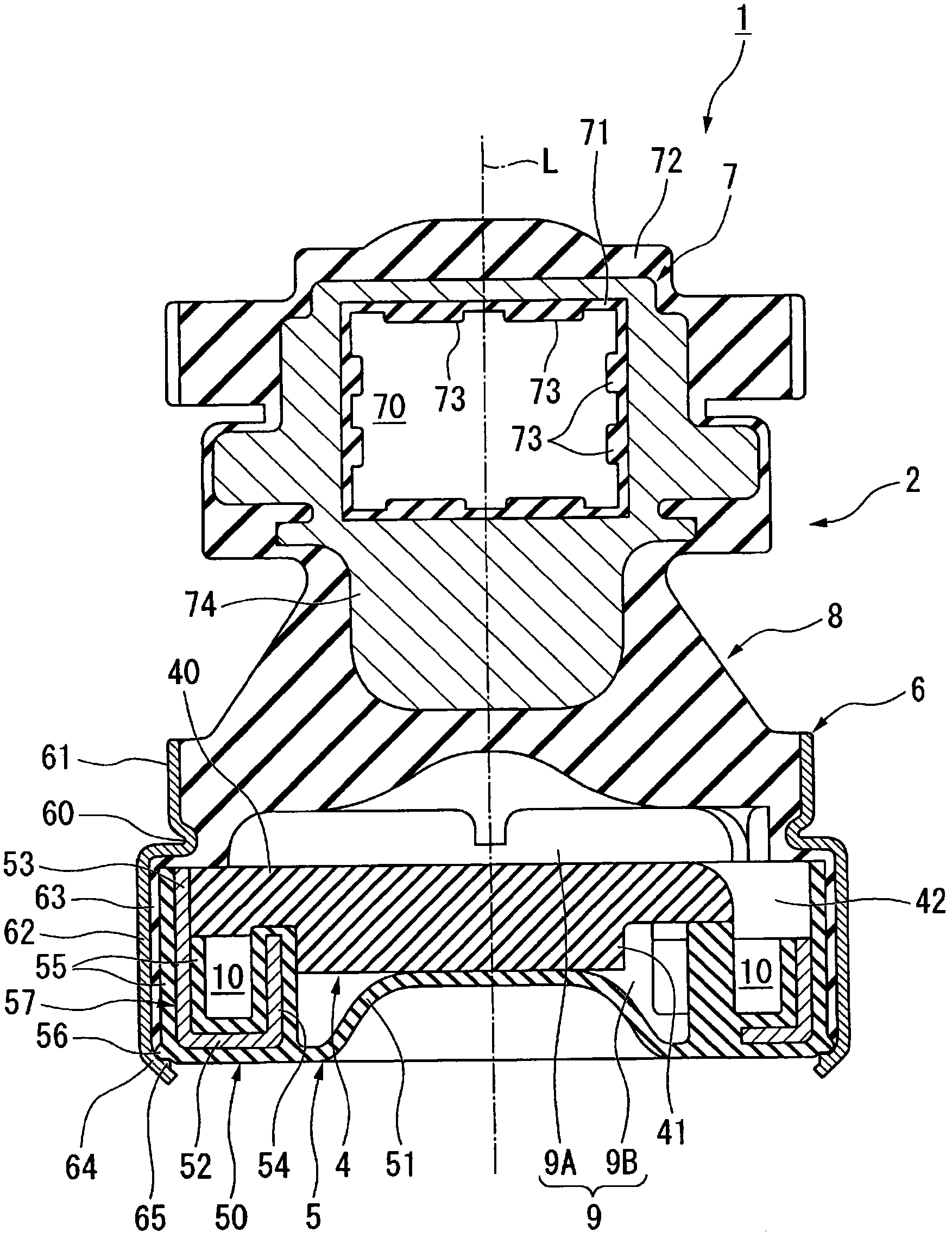

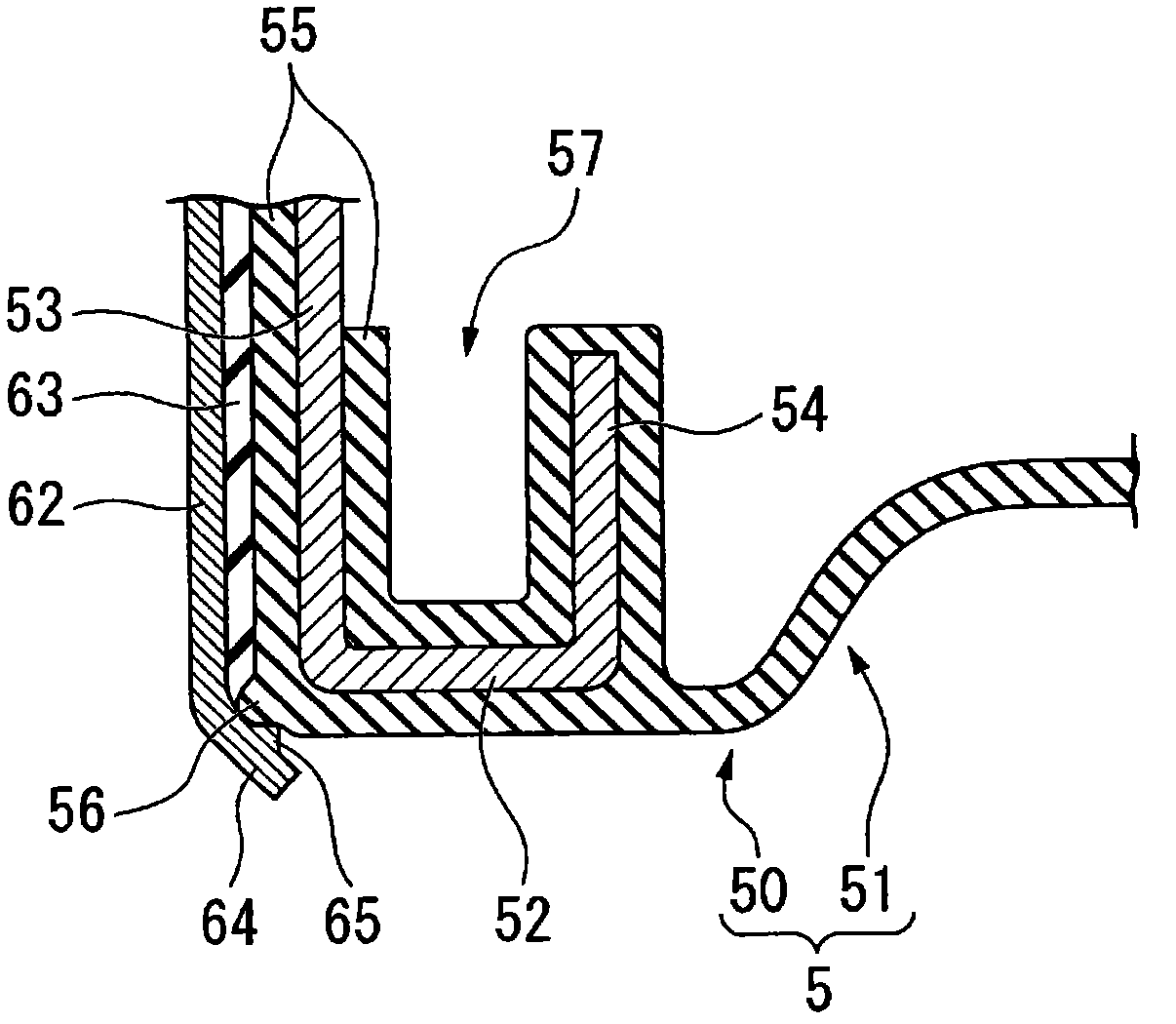

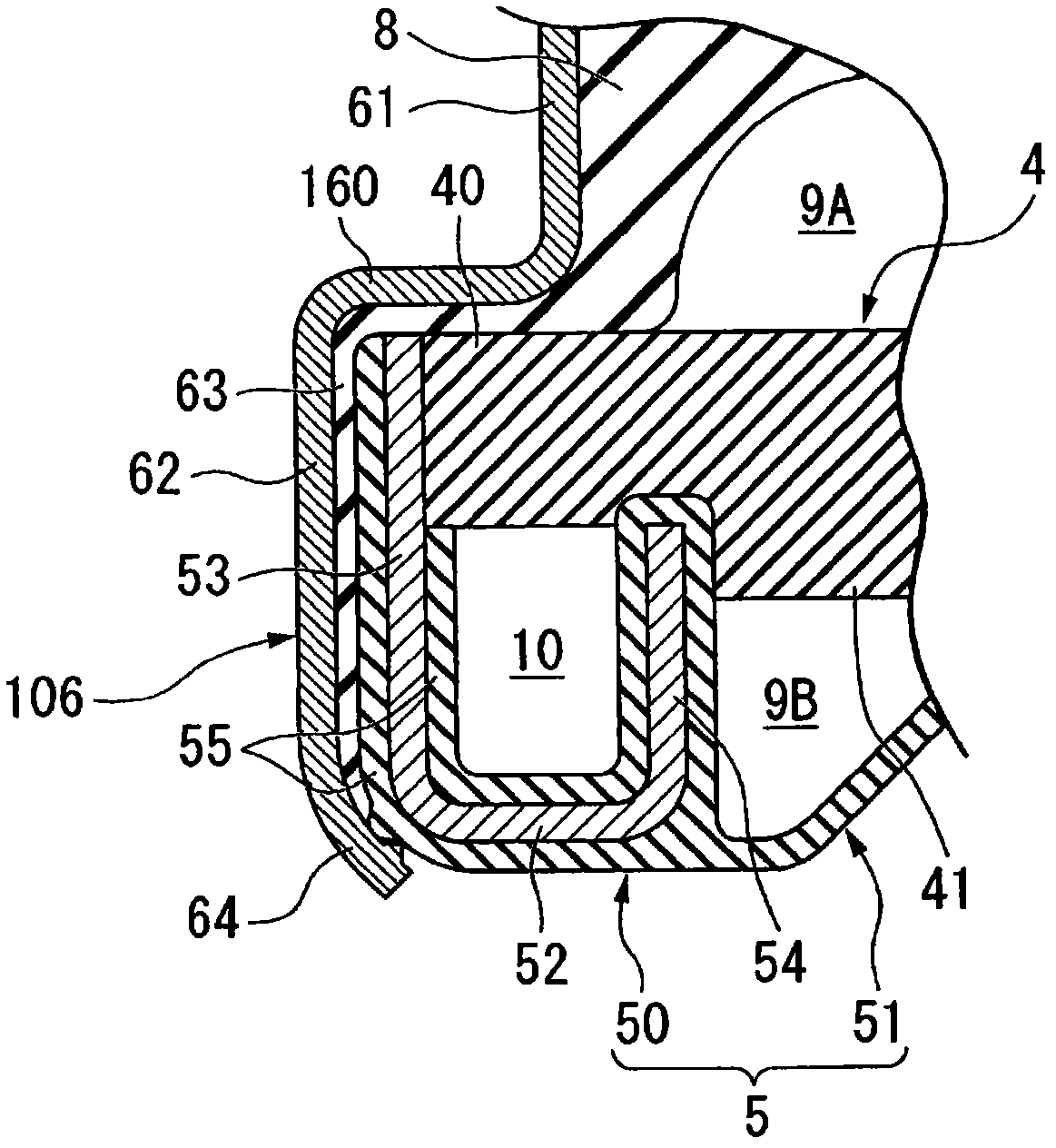

[0029] figure 1 It is a cross-sectional view of the anti-vibration device 1 of this embodiment, figure 2 It is an enlarged cross-sectional view of a part of the anti-vibration device 1 .

[0030] In addition, in this embodiment, in figure 1 The lower side in is the elastic deformation side, that is, the direction in which the static load (initial load) is input when the anti-vibration device 1 is installed. figure 1 The upper side in is the rebound side, that is, the side opposite to the input direction of the above-mentioned static load. In the following description, the elastic deformation side (the other side) is referred to as the lower side, and the rebound side (one side) is referred to as the upper side. In addition, in this embodiment, the axial direction of the inner tube 7 ( figure 1 The direction perpendicular to the paper surface) i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap