Device for measuring screw element at pipe end, system for measuring screw element and method for measuring screw element

一种测量装置、测量方法的技术,应用在测量装置、机械测量装置、采用光学装置等方向,能够解决自动测量困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

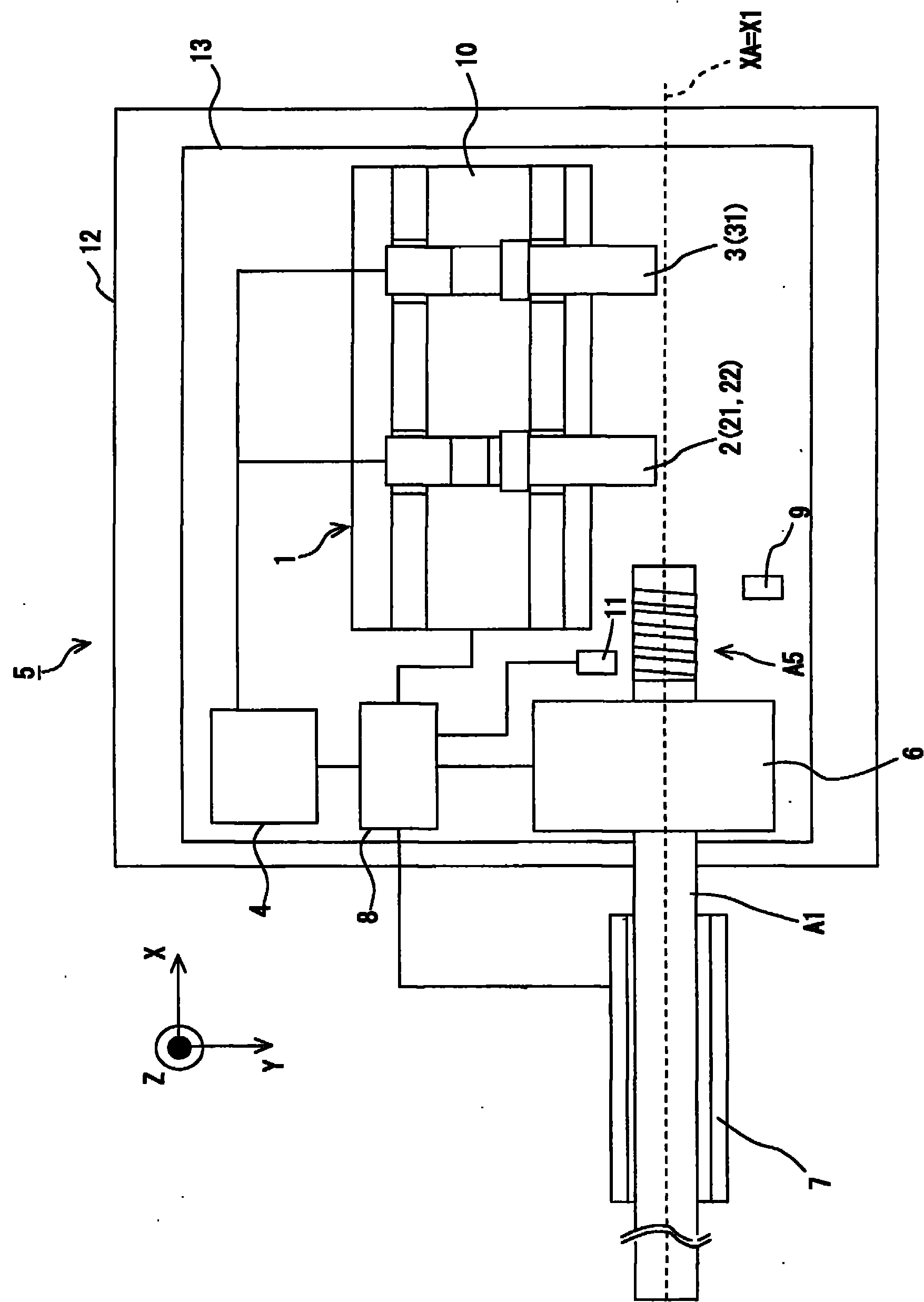

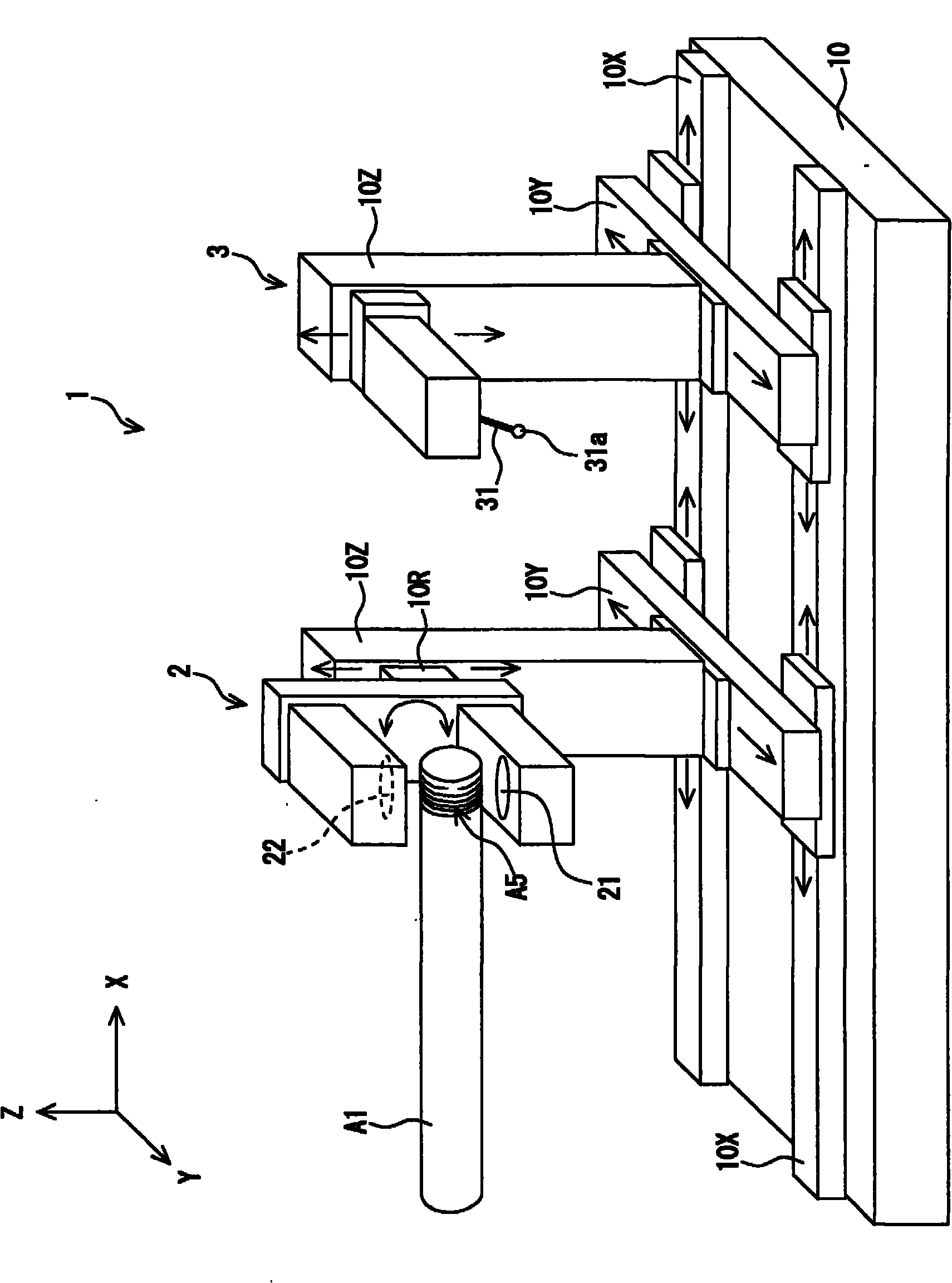

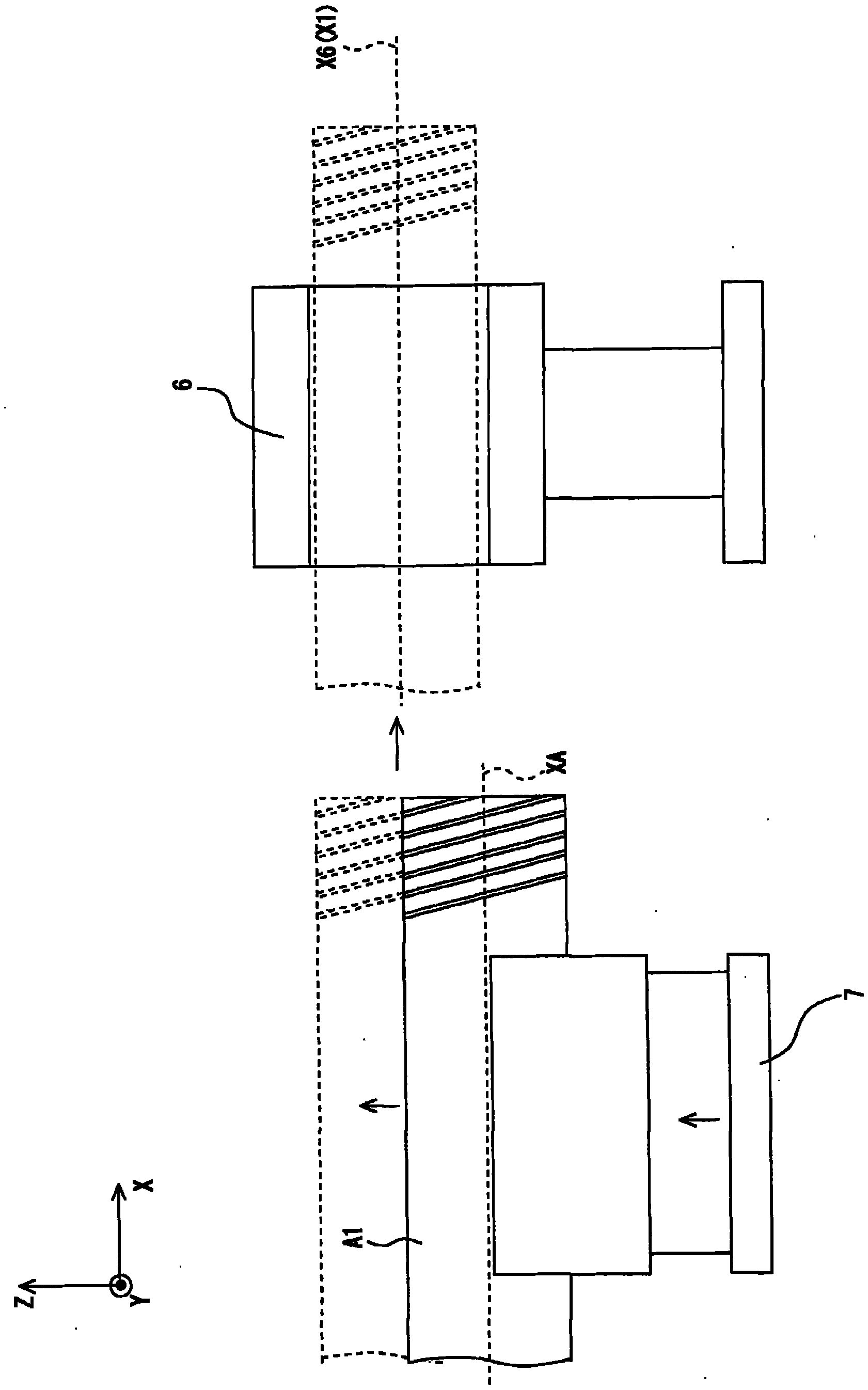

[0092] Below, refer to the attached Figure one The preferred embodiments of the present invention will be described.

[0093] First, a description will be given of the structure of a hook-shaped thread having a hook-shaped flank at the end of a threaded pipe, which is a measurement target of the thread element measuring device of the present invention. In addition, the thread element measuring device of the present invention can also measure threaded pipes having general thread shapes other than hook threads.

[0094] Image 6 Is a schematic cross-sectional view parallel to the axial direction of the pipe end on which the hook thread is formed, Figure 7 Yes Image 6 An enlarged view of one of the threads. In addition, in Image 6 with Figure 7 In order to make it easier to understand, the pitch and size of the thread are deliberately changed to be different from actual ones.

[0095] Formed as Image 6 with Figure 7 The thread A2 on the pipe end of the threaded pipe A1 as shown inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com