Timing control system of diesel engine based on state machine and time processing unit (TPU)

A technology of processing unit and state machine, applied in engine control, electrical control, fuel injection control, etc., can solve problems such as engine failure to run, shorten engine start-up time, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

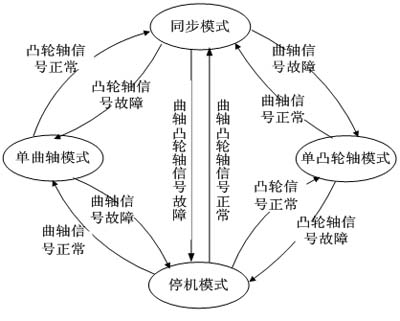

Method used

Image

Examples

Embodiment 1

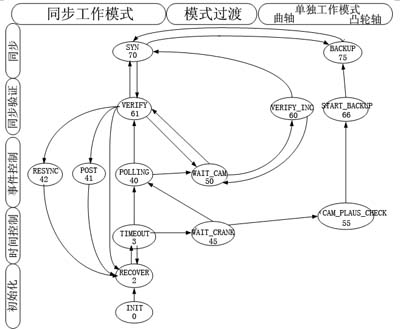

[0021] Example 1: When the crankshaft and camshaft signals are normal, the engine start process:

[0022] When the key switch is in the ON gear, the ECU is powered on, and the system enters the initial state of INIT. Within the set time, the crankshaft overtime fault will first occur, and the system enters the TIMEOUT state. When the key switch is in the START position, the motor drives the engine to rotate. Generally, the crankshaft signal is captured first, and when a valid crankshaft signal is found, it enters the POLLING state; when the cam captures a valid signal, it enters the VERIFY state; when the cam detects a gear increase , verify whether the crankshaft and cam signals are synchronized, if not, continue to wait, otherwise, the system enters the SYN synchronization state, at this time the engine phase management system establishes the engine phase, calculates the current cylinder number, performs engine fuel injection control, and enters SYN at this time state.

Embodiment 2

[0023] Embodiment 2: When the crankshaft signal is normal and the camshaft is faulty, the process of starting the engine:

[0024] When the key switch is in the ON gear, the ECU is powered on, and the system enters the initial state of INIT. When within the set time, the crankshaft overtime fault will occur first, and the system enters the TIMEOUT state at this time. When the key switch is in the START position, the motor drives the engine to rotate. Generally, the crankshaft signal is captured first. When a valid crankshaft signal is found, it enters the POLLING state. At this time, due to a camshaft failure, no valid camshaft signal is found, and the system enters the WAIT_CAM state. , within the set number of faults, the crankshaft and camshaft signals cannot be synchronized normally, and the timing system starts the test spray function. If the acceleration is greater than the set threshold, it means that the test spraying is successful, and the system enters the SYN state...

Embodiment 3

[0025] Embodiment 3: When the camshaft signal is normal and the crankshaft is faulty, the process of starting the engine:

[0026] When the key switch is in the ON gear, the ECU is powered on, and the system enters the initial state of INIT. When within the set time, the crankshaft overtime fault will occur first, and the system enters the TIMEOUT state at this time. When the key switch is in the START position and the motor drives the engine to rotate, under normal circumstances the crankshaft signal is captured first, but at this time due to the crankshaft signal failure, no valid crankshaft signal is found, the system first finds a valid cam signal, and the system enters the WAIT_CRANK state. When the cam gear is increased, the system enters the CAM_PHASE_CHECK state. If the synchronization of the crankshaft and camshaft signals is not completed within the set time, the system enters the START_BACKUP state. The engine phase is established according to the camshaft signal, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com