Variable-displacement gear type oil pump

A gear and displacement technology, applied in the direction of lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of reducing engine economy, oil temperature rise, drainage, etc., to improve efficiency and economy, reduce power loss, Guaranteed safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

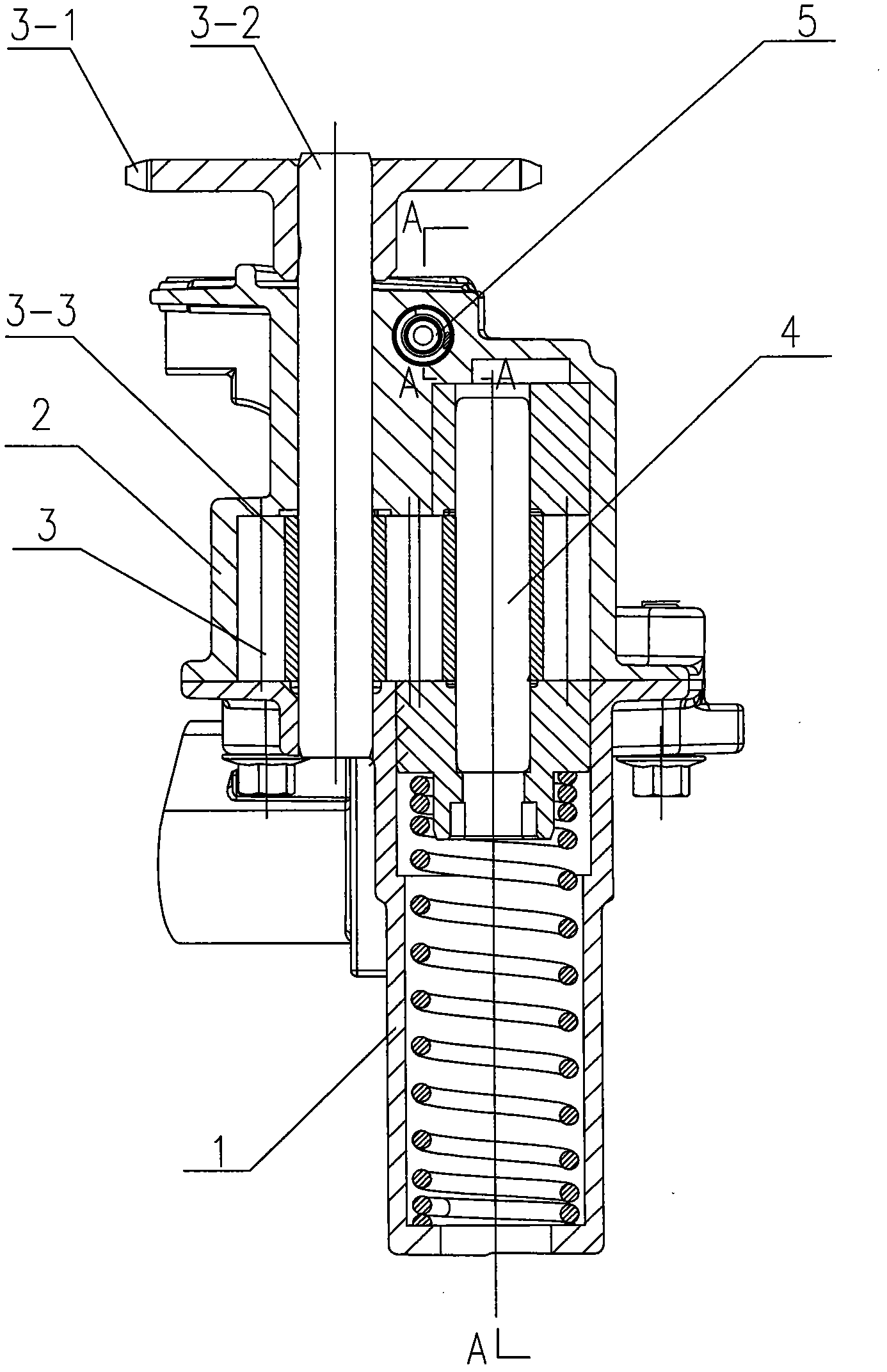

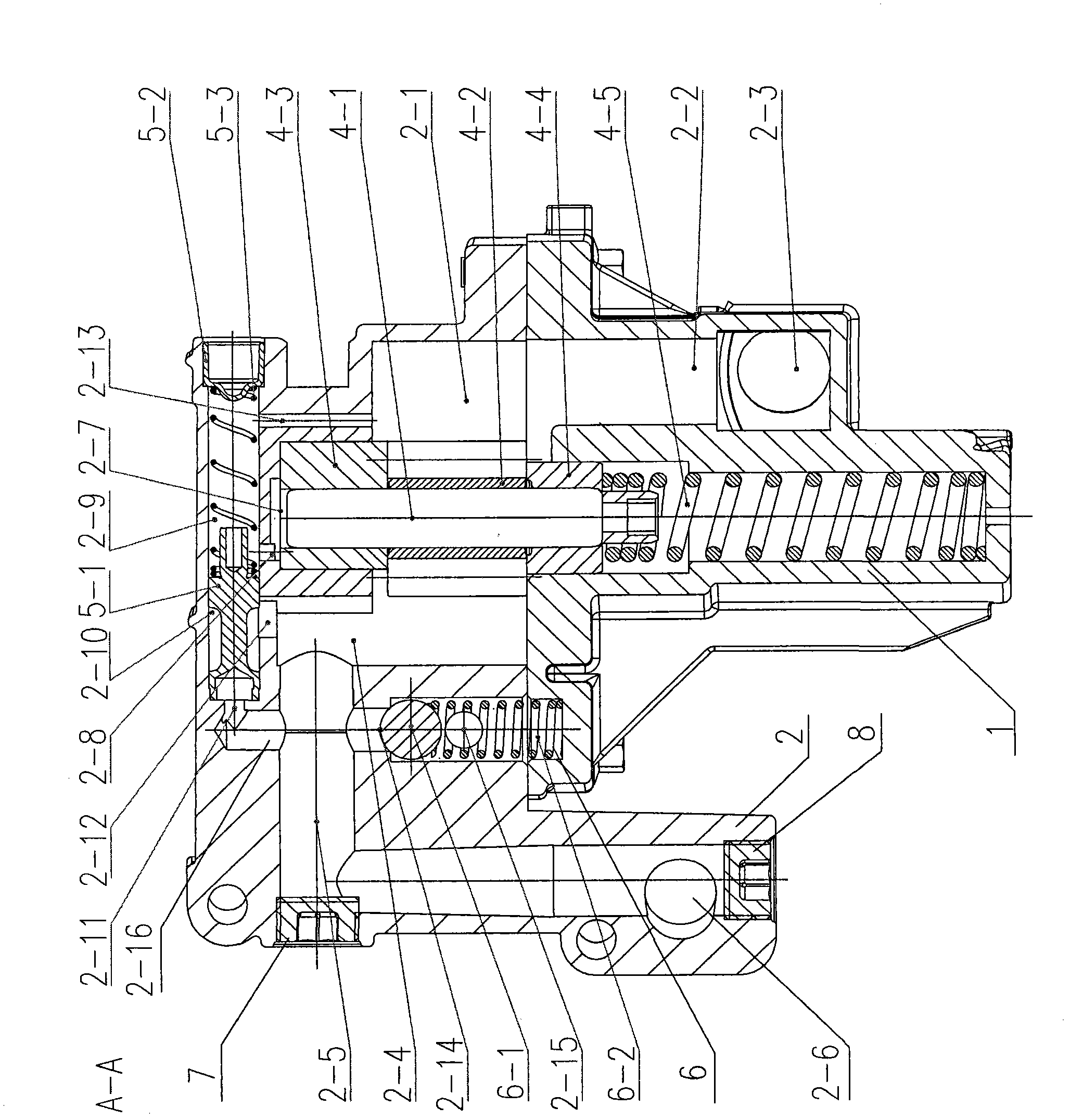

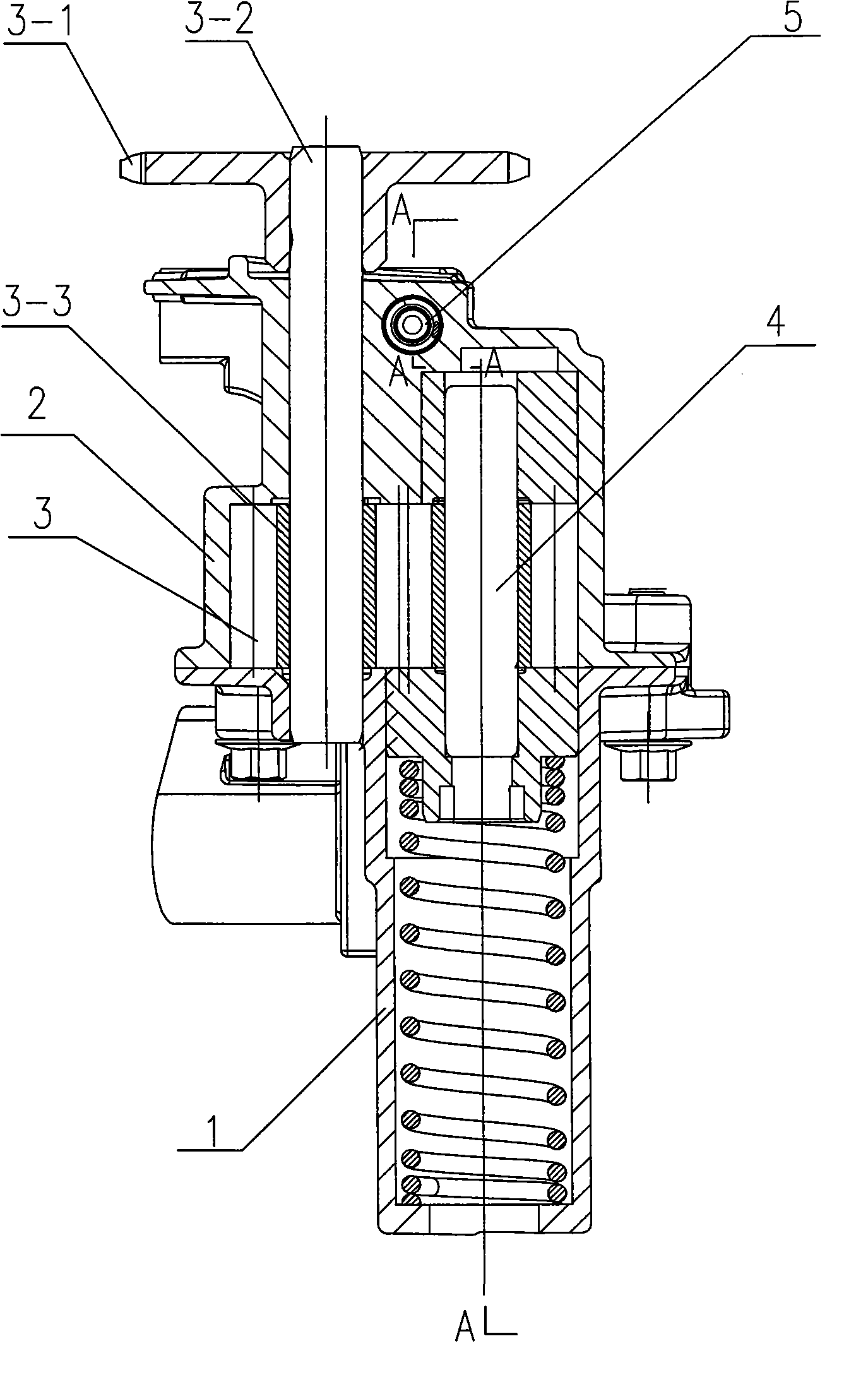

[0016] As shown in the accompanying drawings: a variable displacement gear oil pump, which includes a pump cover 1, a pump body 2, a driving gear transmission part 3, a driven gear variable part 4, a control valve part 5 and a safety valve part 6, The pump cover 1 and the pump body 2 are connected together by bolts.

[0017] The driving gear transmission part 3 is composed of a transmission gear 3-1, a driving shaft 3-2 and a driving gear 3-3. -1 interference connection, the middle part is interference connection with the driving gear 3-3, the driving gear 3-3 has no axial movement, and undertakes the rotation function of the gear pump.

[0018] Driven gear variable part 4 is made up of driven shaft 4-1, driven gear 4-2, missing circle slider 4-3, full circle slider 4-4 and spring 4-5. One end of the driven shaft 4-1 is in interference connection with the half-circle slider 4-2, the middle part is in motion-fit connection with the driven gear 4-2, and the other end is in inte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap