Method for starting motor without sensor

A motor starting and sensor technology, which is applied in the direction of controlling generators, motor generators, and electromechanical transmissions, etc., can solve problems such as poor versatility, failure to start, and inability to operate the motor, so as to improve the success rate of switching and achieve universal The effect of strong resistance and no sudden change of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

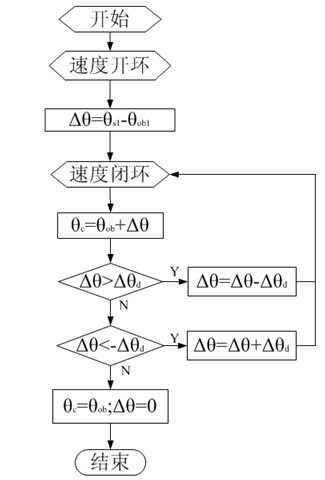

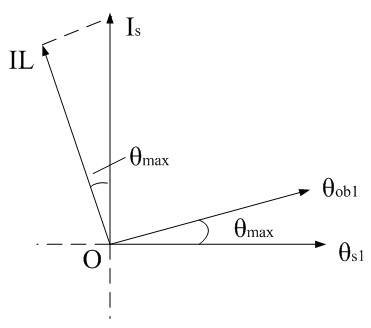

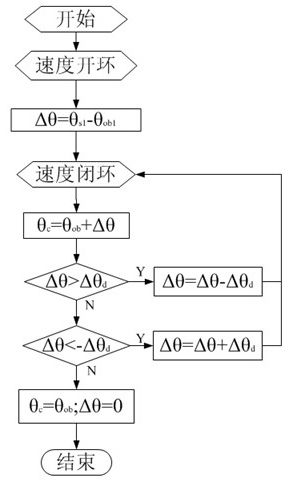

[0023] The gist of the present invention is to solve the problem of sensorless control of permanent magnet motors in the prior art. When the permanent magnet motor is started, the speed open-loop control is switched to the speed closed-loop control. There is an angle difference in the estimated position value. When the estimated value of the rotor position is directly used for speed closed-loop control, the control variable will jump and change continuously and smoothly. A sensorless motor starting method is provided to avoid motor control effects. Abrupt mutation, strong current oscillation, strong vibration of the motor, etc., to ensure the successful start of the motor, and this method is not affected by the load characteristics of the motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com