Hemodialysis concentrated liquid preparing machine

A technology of hemodialysis and concentrated solution, which is applied in the field of hemodialysis, can solve the problems that cannot overcome the pollution of hemodialysis concentrated solution, and achieve the effects of avoiding medical safety accidents, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

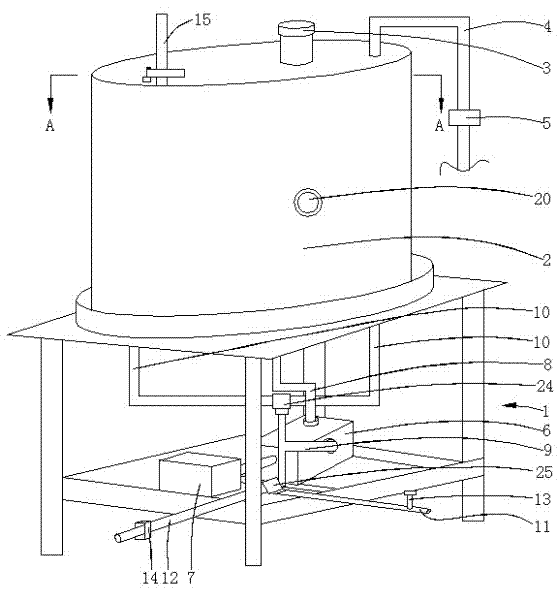

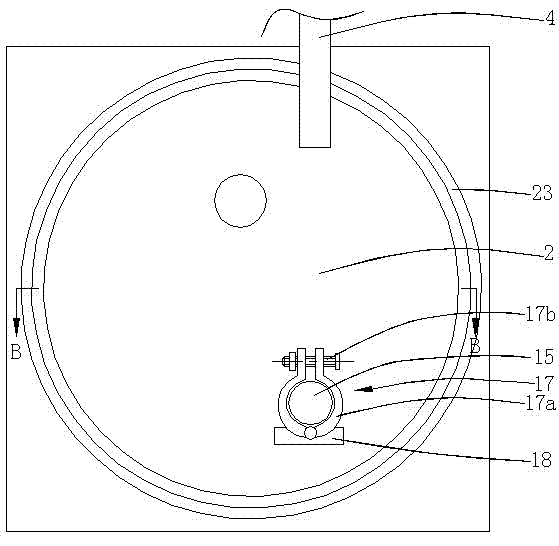

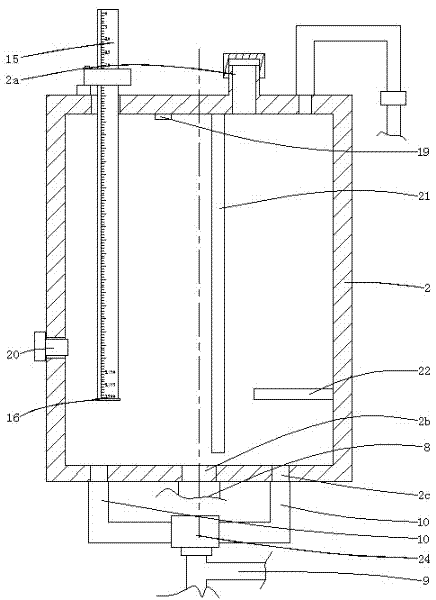

[0022] Such as Figure 1~5 As shown, a hemodialysis concentrated solution dispensing machine consists of a frame 1, a liquid dispensing barrel 2, a sealing cover 3, a water adding pipe 4, a first electromagnetic valve 5, a water pump 6, a motor 7, an outlet pipe 8, and a three-way pipe 9. Water return pipe 10, finished product liquid output pipe 11, disinfectant liquid discharge pipe 12, second solenoid valve 13, valve 14, hollow pipe 15, first liquid level sensor 16, hoop 17, fixed block 18, second liquid level Sensor 19, plugging cover 20, ultraviolet lamp 21, resistance heater 22 and other parts constitute. The frame 1 is composed of four columns 1a, four lower beams 1b, a support bar 1c and a table top 1d, wherein the four columns 1a are distributed in a rectangular shape, and the table 1d is arranged above the column 1a, and the table 1d is below the table 1d. The plate surface is fixed to the upper end surface of the column 1a, and a limit ring 23 is horizontally arrang...

Embodiment 2

[0027] refer to Figure 6 , in this embodiment, the water outlet hole 2b is opened at the center of the circular liquid dispensing barrel 2, and the right two return holes 2c are opened at the bottom of the liquid dispensing barrel 2 on the side of the water outlet hole 2b, and the other water outlet holes 2b A water return hole 2c is provided at the bottom of the liquid dispensing barrel 2 on one side. As an optimization, the centers of the three backwater holes 2c are located on the same circle, and the three backwater holes 2c are evenly arranged on the circle. The rest of the structure of this embodiment is exactly the same as that of Embodiment 1, and will not be repeated here. .

Embodiment 3

[0029] refer to Figure 7 , in this embodiment, the water outlet hole 2b is opened at the center of the circular liquid dispensing barrel 2, and the right two return holes 2c are opened at the bottom of the liquid dispensing barrel 2 on the side of the water outlet hole 2b, and the other water outlet holes 2b Two water return holes 2c are also provided at the bottom of the liquid dispensing barrel 2 on one side. As an optimization, the centers of the four backwater holes 2c are located on the same circle, and the four backwater holes 2c are evenly arranged on the circle. The rest of the structure of this embodiment is exactly the same as that of Embodiment 1, and will not be repeated here. .

[0030] The working principle of the present invention is as follows:

[0031] Before use, first close the second solenoid valve 14 on the disinfectant discharge pipe 12 and the valve 13 on the product liquid output 11, add high-concentration disinfectant into the liquid distribution ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com