Rubber stopper conveying mechanism

A technology of conveying mechanism and rubber plug, which is applied to conveyor objects, threadless plugs, transportation and packaging, etc., can solve problems such as collapse or jamming, and achieve low cost, simple and compact structure, easy guidance and different position limits. The effect of the specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

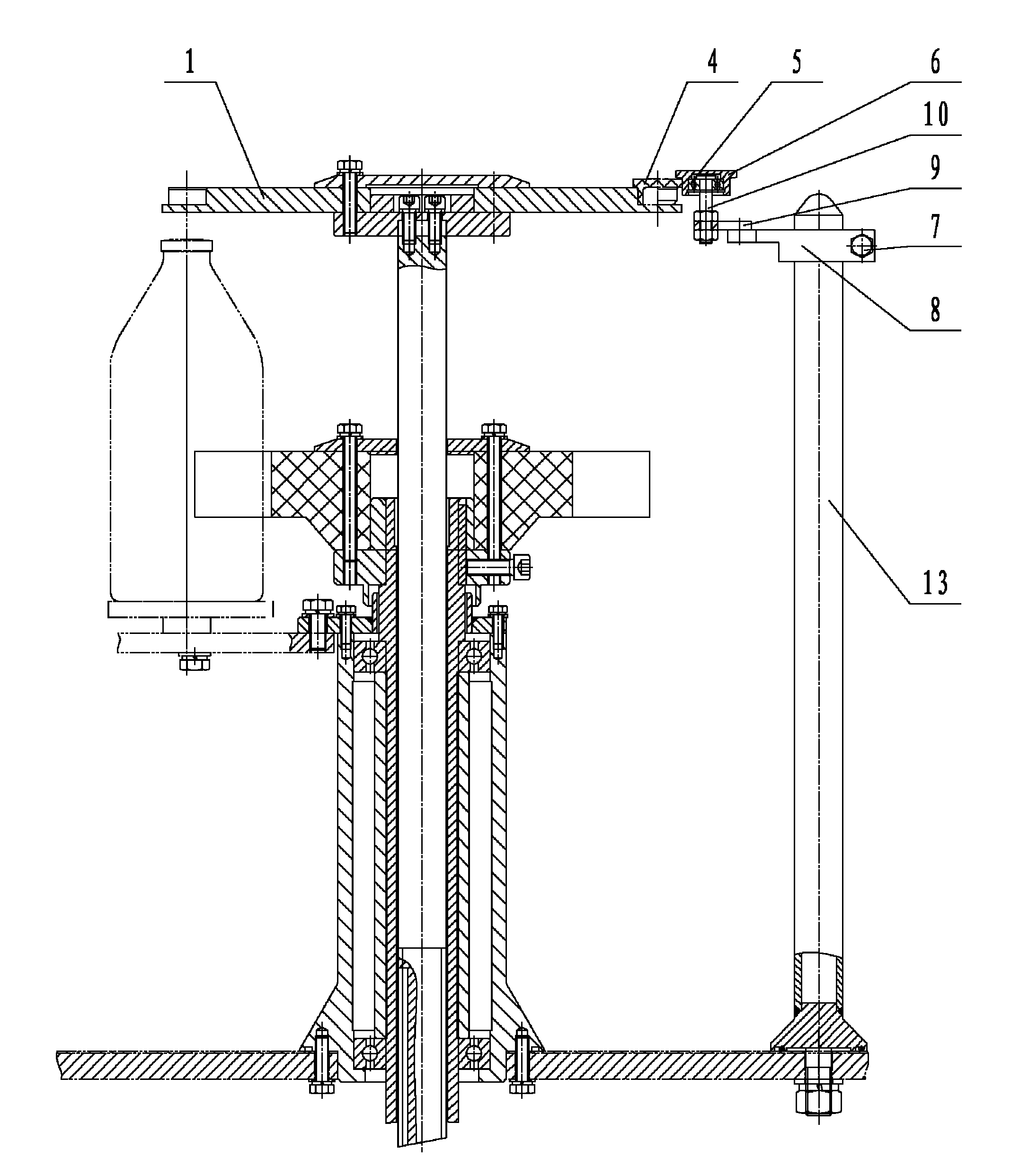

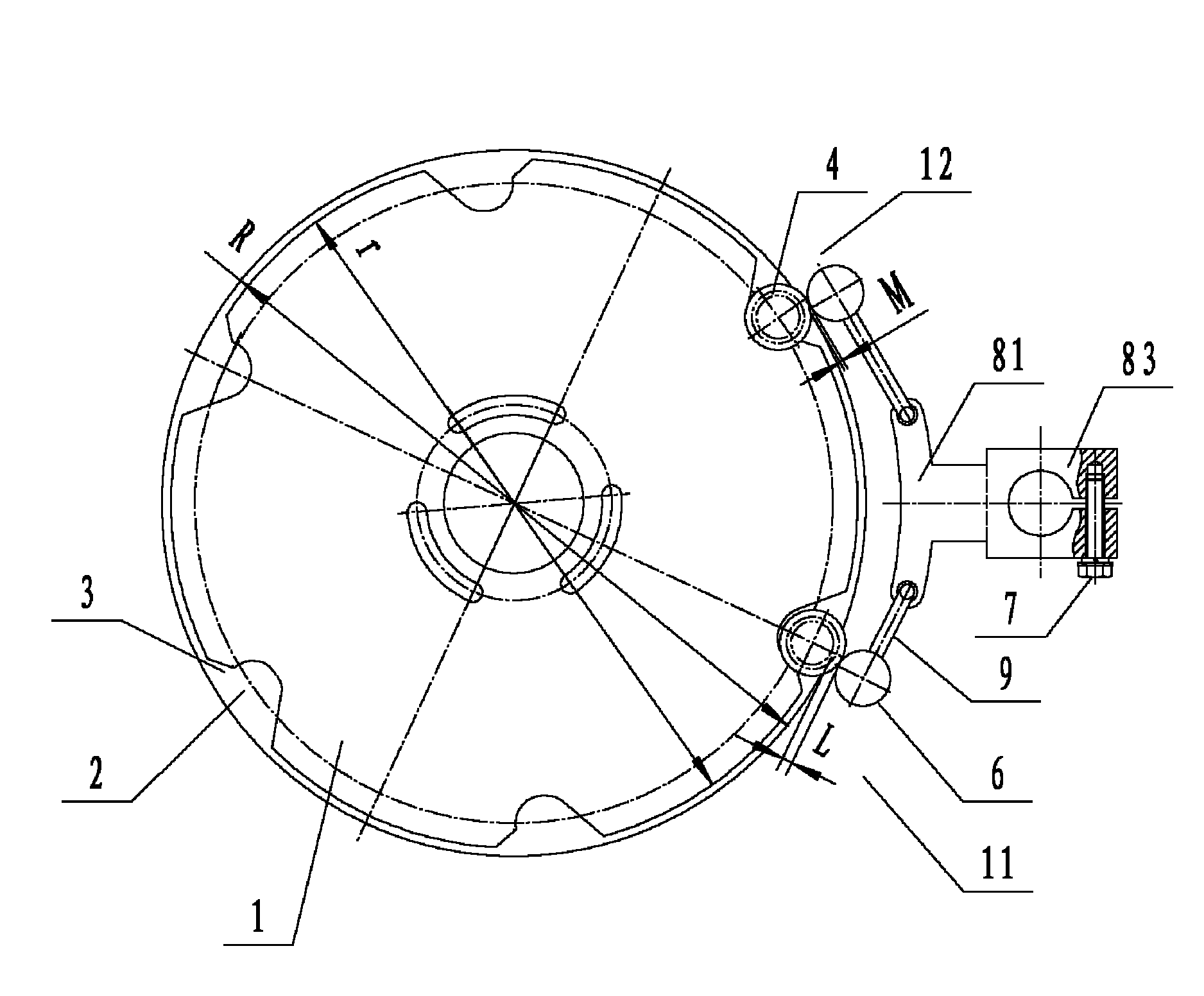

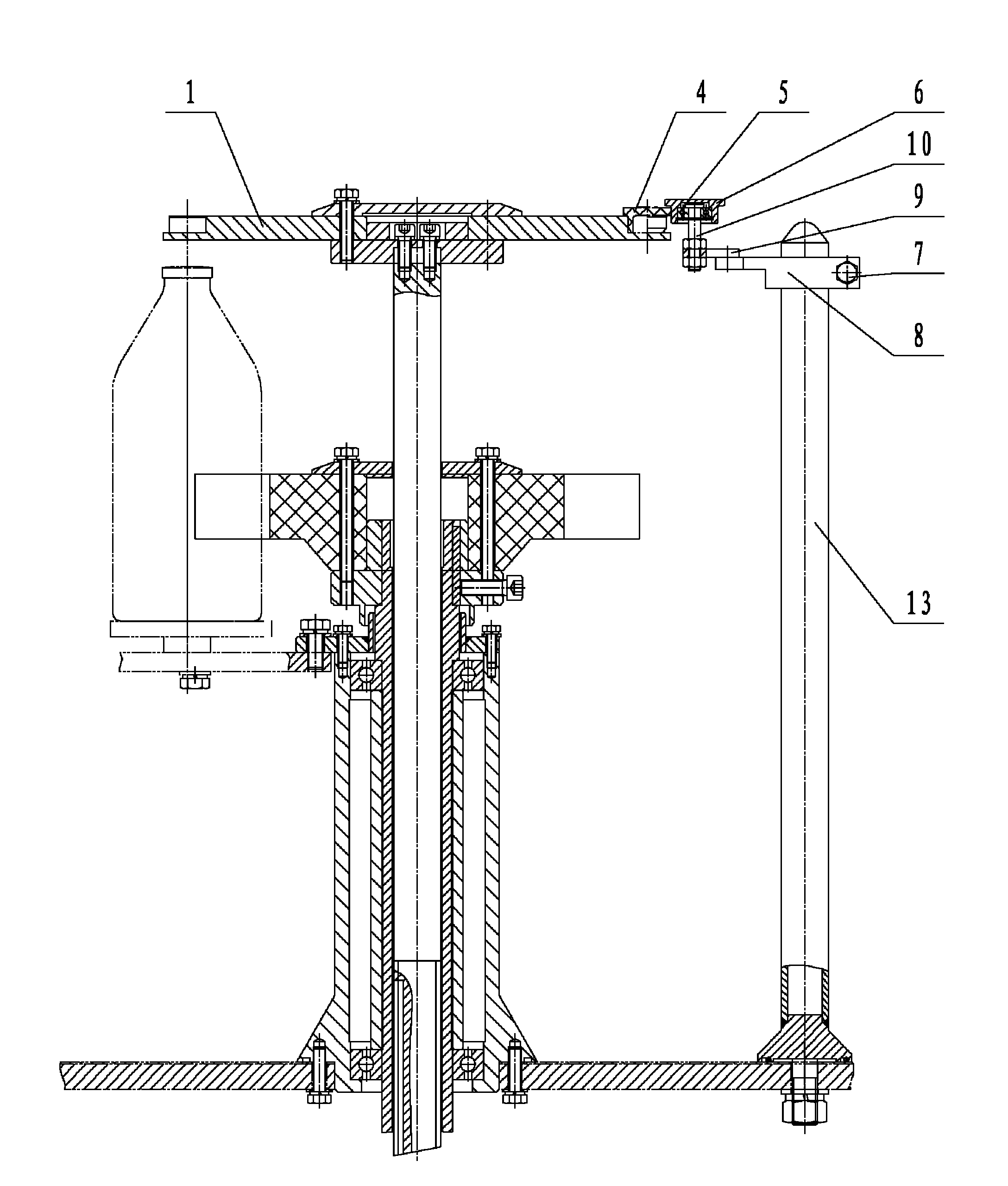

[0020] figure 1 and figure 2 It shows an embodiment of a rubber stopper conveying mechanism of the present invention, the mechanism includes an upper stopper plate 1, and the outer edge of the upper stopper plate 1 is provided with a stopper accommodating groove 2 and an avoidance groove 3 connected with the stopper accommodating groove 2 , The periphery of the upper plug disc 1 is provided with a rolling member 5 for guiding and limiting the rubber plug 4 in the plug accommodating groove 2 . The rubber plug conveying mechanism of the present invention has a simple and compact structure and low cost. During the process of the upper plug plate 1 rotating and conveying the rubber plug 4, only a rolling friction force is generated between the rubber plug 4 and the rolling member 5, and the rolling friction force is relatively small Instead of driving the rubber plug 4 to squeeze into the escape groove 3 with a smaller diameter, the phenomenon of plugging or jamming can be avoid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap