Method for synthesizing (+/-)-9-O-demethyl-alpha-dihydrotetrabenazine

A technology of dihydrotetrabenazine and -9-O-, which is applied in the field of drug synthesis, can solve the problems of inability to be widely used in industry, low conversion rate, and poor repeatability, and achieve reasonable step design, high conversion rate, and economical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

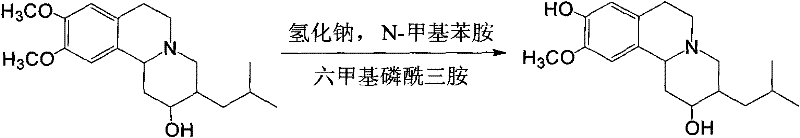

[0029] The synthetic steps of (±)-9-O-desmethyl-α-dihydrotetrabenazine are as follows:

[0030] Add sodium hydride and hexamethylphosphoric triamide to xylene, add N-methylaniline dropwise after heating to 90°C, and stir for 15 minutes; add (±)-α-dihydrobutylbenzene dropwise to the above reaction mixture After the addition of the xylene suspension of nazine is completed, the reaction suspension is continuously stirred at 90°C for 48 hours; an aqueous sodium hydroxide solution is slowly added to the above reaction suspension, and the water phase is separated, and the water phase is neutralized by aqueous hydrochloric acid to After the pH value was 7, it was extracted with ether, and the organic phase was concentrated under reduced pressure to obtain a light brown solid; the above light brown solid was purified by column chromatography to obtain the compound (±)-9-O-desmethyl-α-dihydrobutanol benazine. The column chromatography purification steps are as follows: Weigh the silic...

Embodiment 2

[0033] The synthetic steps of (±)-9-O-desmethyl-α-dihydrotetrabenazine are as follows:

[0034] Add sodium hydride and hexamethylphosphoric triamide to xylene, add N-methylaniline dropwise after heating to 100°C, and stir for 20 minutes; add (±)-α-dihydrobutylbenzene dropwise to the above reaction mixture After the addition of the xylene suspension of nazine is completed, the reaction suspension is continuously stirred at 100°C for 50 hours; an aqueous sodium hydroxide solution is slowly added to the above reaction suspension, and the water phase is separated, and the water phase is neutralized by aqueous hydrochloric acid to After the pH value was 9, it was extracted with ether, and the organic phase was concentrated under reduced pressure to obtain a light brown solid; the above light brown solid was purified by column chromatography to obtain the compound (±)-9-O-desmethyl-α-dihydrobutanol benazine. The column chromatography purification steps are as follows: Weigh the sil...

Embodiment 3

[0037] The synthetic steps of (±)-9-O-desmethyl-α-dihydrotetrabenazine are as follows:

[0038] Add sodium hydride and hexamethylphosphoric triamide to xylene, add N-methylaniline dropwise after heating to 95°C, and stir for 18 minutes; add (±)-α-dihydrobutylbenzene dropwise to the above reaction mixture After the addition of the xylene suspension of nazine is completed, the reaction suspension is continuously stirred at 95°C for 49 hours; an aqueous sodium hydroxide solution is slowly added to the above reaction suspension, and the water phase is separated, and the water phase is neutralized by aqueous hydrochloric acid to After the pH value was 8, it was extracted with ether, and the organic phase was concentrated under reduced pressure to obtain a light brown solid; the above light brown solid was purified by column chromatography to obtain the compound (±)-9-O-desmethyl-α-dihydrobutanol benazine. The column chromatography purification steps are as follows: Weigh the silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com